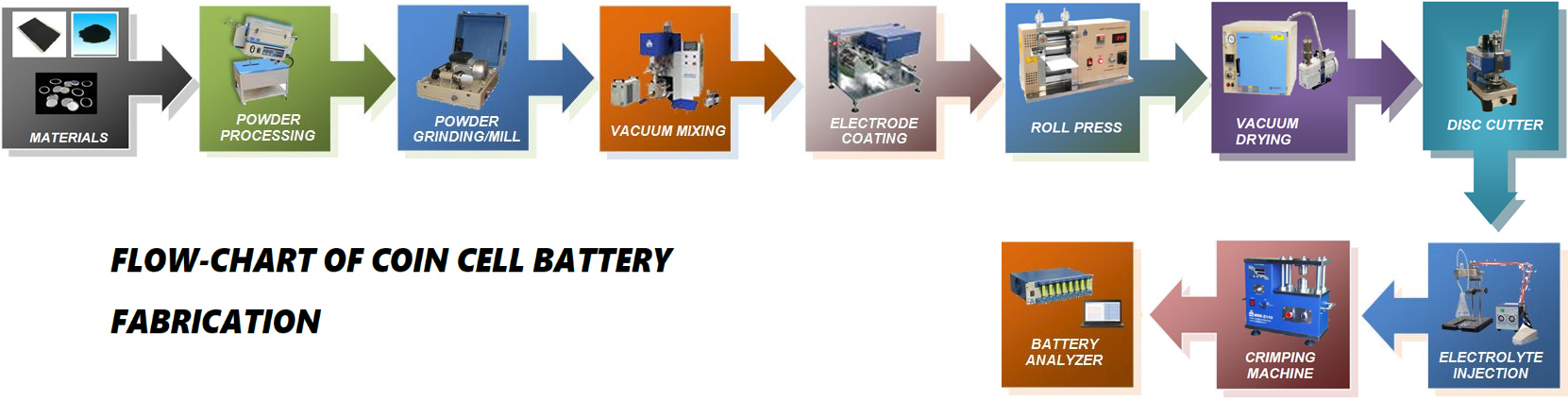

Coin Cell Fabrication Process Overview

The following videos give a general idea of how a coin cell battery is made using MTI's equipment.

Simplified Quick Overview: From Electrode Coating to Cycle Testing

Slurry Preparation:

- Mill and dry the electrode material.

- Mix a slurry solution: Click Here for a Simple Slurry Recipe

Tape Casting Coater for coating slurry on electrode foil.

Dry the coated electrode :

Roll the electrode to reduce its thickness.