Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

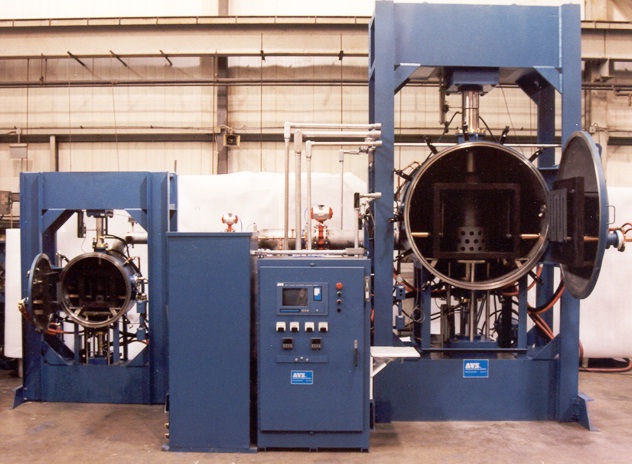

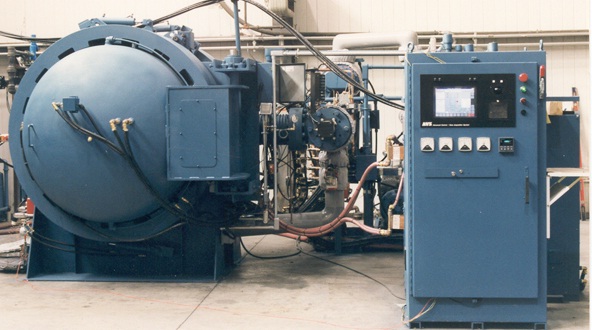

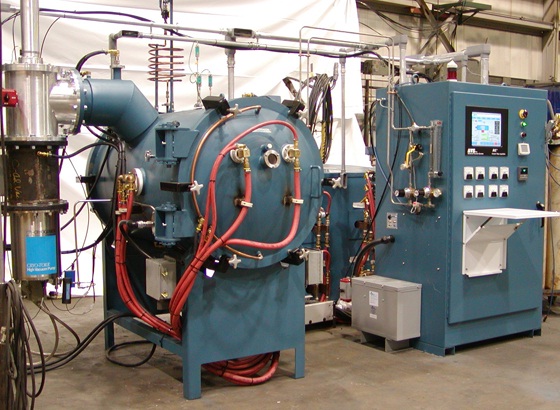

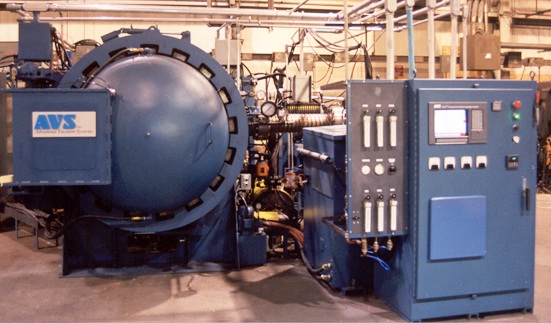

AVS Inc , USA

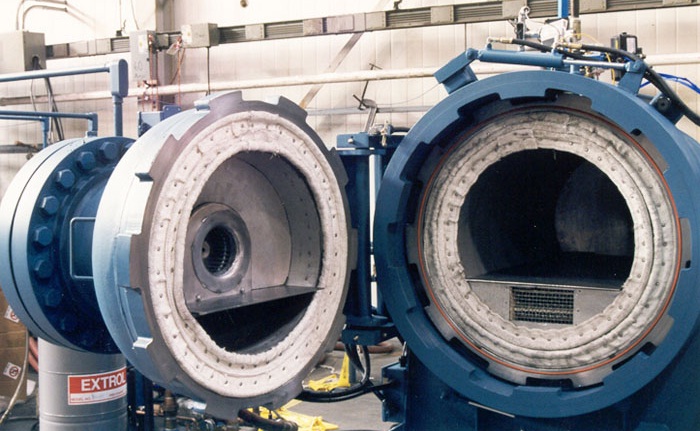

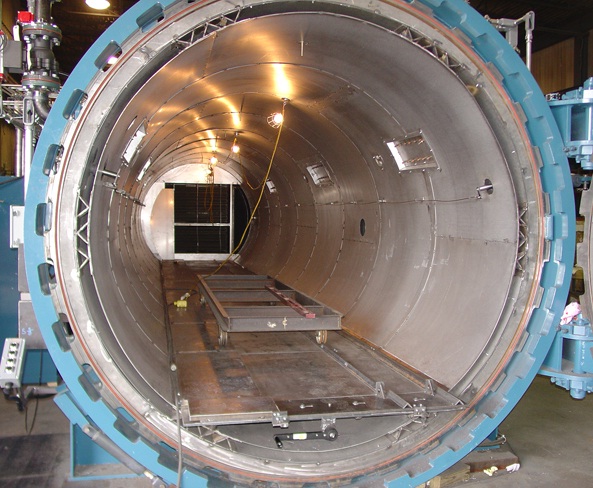

Since 1967, AVS has been providing custom vacuum furnaces and pressure furnaces to customers around the world. AVS primary manufacturing facility in Ayer, Massachusetts, has in-house capabilities that include furnace design, engineering, ASME certified welding, controls engineering, design, and complete integration of complex, fully customized furnace systems. From inception through manufacture, final assembly, and technical support, every AVS / Premier Solutions employee is invested in your success and dedicated to engineering your complete furnace solution. AVS collaborative partnerships with customers worldwide have resulted in thousands of success stories. Put our 40 years of experience to work for your product success.

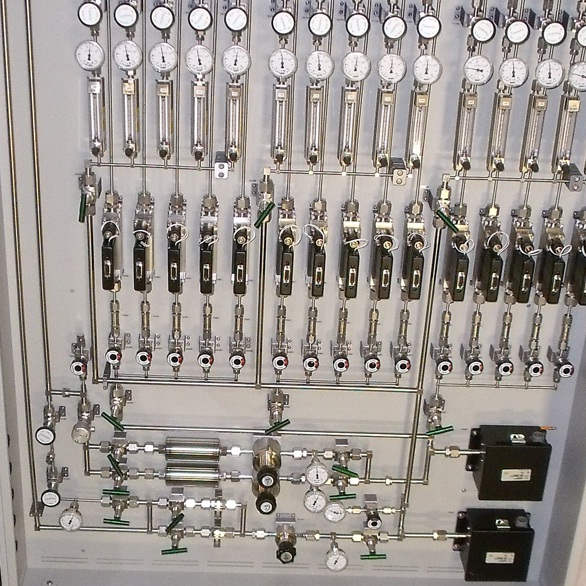

AVS supplies total furnace solutions. Whether heated by resistance or induction, AVS furnace specifications originate with the customer. To provide the right furnace, AVS utilizes the customer’s intimate process knowledge to determine the ideal performance criteria. The customer specifications of size, weight, temperature, uniformity, vacuum, pressure, and gas atmosphere conditions are the foundation of the final AVS furnace.

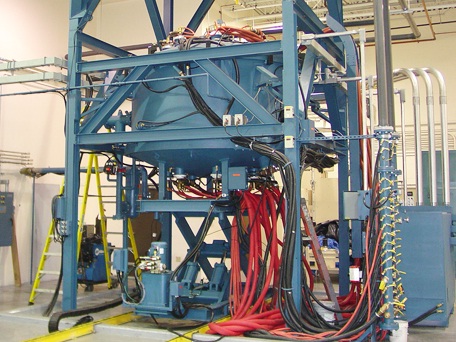

AVS fabrication capabilities can accommodate furnaces ranging in size from 4 inch (100mm) diameter mini furnaces to hot zones in excess of 12 feet (4 meters). AVS has in-house capabilities to fabricate graphite hot zones or metal hot zones. AVS manufactures furnaces for applications involving combinations of high temperatures to 3000°C, high vacuum to 10-6 torr, and gas pressures up to 3000 psig (200 bar). AVS hot presses have ranged from 5 tons to more than 2000 tons of hydraulic force.

AVS stands alone in the industrty, willing to build custom furnaces that enable customers to combine several processes for the most advanced, customer-confidential applications.