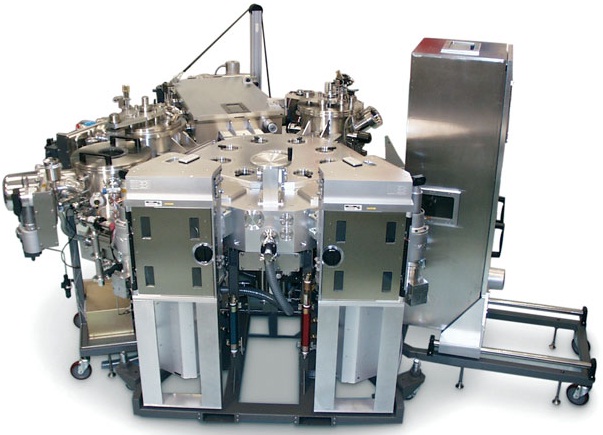

Kurt J. Lesker OCTOS®—A fully automated cluster tool for pilot production scale processing of substrates requiring in-vacuum substrate transfer between chambers

Leading display device manufacturers use Kurt J. Lesker OCTOS to advance OLED technologies.

Kurt J. Lesker OCTOS®—A fully automated cluster tool for pilot production scale processing of substrates requiring in-vacuum substrate transfer between chambers

Leading display device manufacturers use Kurt J. Lesker OCTOS to advance OLED technologies.

- Offers exceptional layer thickness uniformity, repeatability, and reliability sought by OLED/PLED and GMR customers alike

Typical Applications

- OLED/PLED R&D or Production

- GMR Magnetic Films R&D or Production

- Photovoltaic R&D or production (PV, OPV)

- Organic Electronics

Deposition Techniques Available

- Magnetron Sputtering (RF, DC, or Pulsed DC)

- Thermal Evaporation, including Metal Inorganic Evaporation

- Organic Evaporation, including OLED/PLED, organic photovoltaic, organic TFT applications

- ALD

- Electron Beam Evaporation/li>

Process Options

- Heating

- Cooling

- Bias

- Ion Source for Substrate Cleaning/Assisted Deposition

- UHV Option

Features

- Automated entry and exit locks with multi-sample cassette

- Fully automated robotic sample transfer system

- Available with up to 6 process chambers for standard HV OCTOS platform

- Linear Sputtering Chamber – Available with Linear Magnetron Sputter Sources

- Organic Evaporation Chamber – Available with up to 9 low-temperature organic evaporation sources

- Metal Evaporation Chamber – Available with up to 4 thermal evaporation sources

- Reactive Plasma Chamber – Features parallel plate RF etching

- Mask-Changing Module – 20-mask storage capacity with mask holders

Lesker OCTOS - Automated Cluster Tool