Today, at the request of customers, Calibrating the FSM 128 that they bought。

The FSM 128 is an automated stress measurement tool. This tool measures wafer curvature, bow and other important information using a non-contact technique that will not damage the wafer. FSM 128 is designed to measure the amount of curvature of semiconductor wafers in a production environment requiring high reliability and performance.

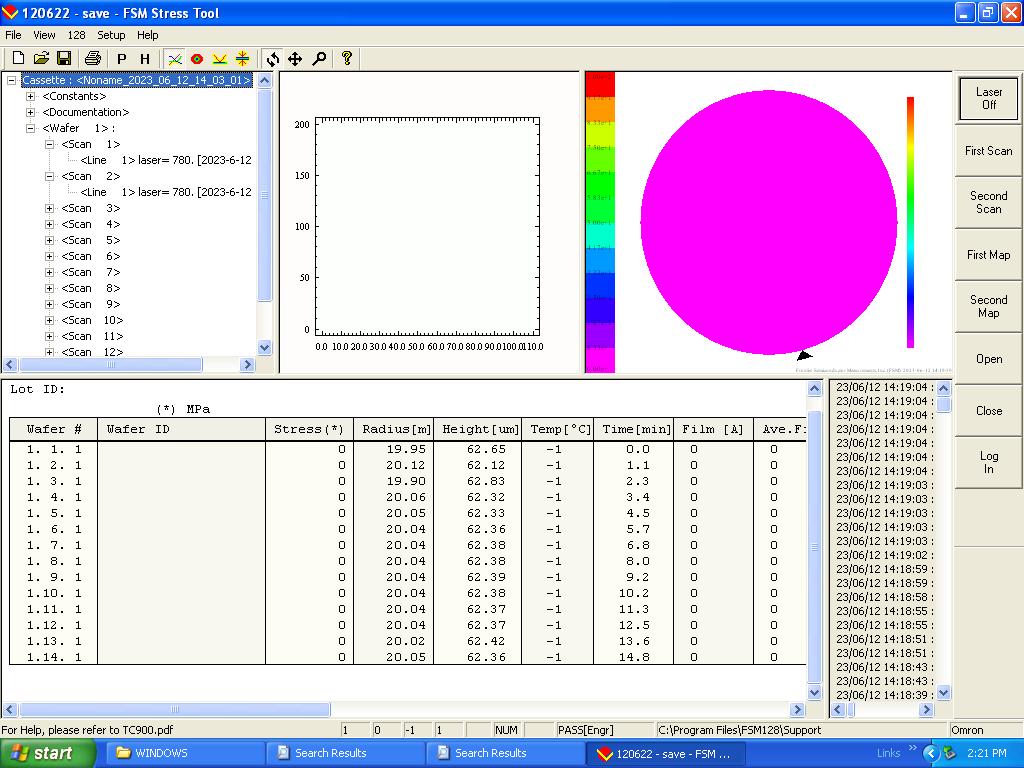

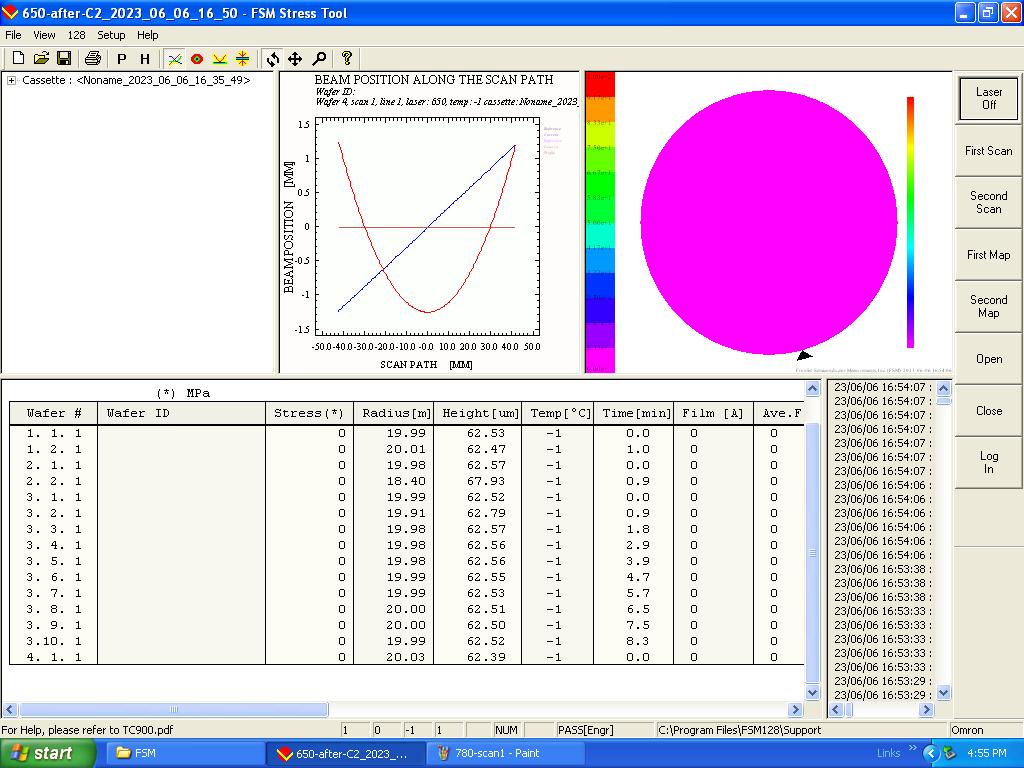

We calibrated the two laser heads of FSM128, which are 780 and 650 wavelengths respectively. The calibration is done by scanning the 20 meter mirror and measuring 20 meters +/-0.1 meters. Each wavelength of the laser makes 14 scans,

780 wavelengths

650 wavelengths

The scan results of 14 times after calibration meet the requirements, and the customer is satisfied with the acceptance!