Furnace Structure

| - Double-layer steel structure with air cooling to keep case temperature < 65oC

- Vertical and splittable for easy installation.

- Liquid quenching tank is connected to a 4" quartz tube via a gate valve and allow sample drop to the liquid container

- Click the picture left for detail

|

Power | 3 KW |

Voltage | AC 208-240V Single Phase, 50/60 Hz |

Max. Temperature | 1000oC < 1 hrs |

Continuous Temperature | 900oC < continuous |

Max. Heating Rate | <= 20oC /min, recommended heat: <= 10oC /min |

Tube Size and Materials | - One 101 OD x 92 ID x 1000L mm (4" x 40") Stainless Steel Tube is included

|

Heating Zone | - Heating Zone length: 440mm

- Constant Temperature: 150 mm ( within+/- 1oC)

|

Temperature Controllers | - 30 programmable segments for precise control of heating rate, cooling rate, and dwell time.

- Built-in PID Auto-Tune function with overheating & broken thermocouple broken protection.

- Over-temperature protection and alarm allow for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

- One K-type thermocouple.

- RS485 Communications Port.

|

Hydrogen Detector System

(included) (included) | One Honeywell UL Approved Sensepoint Gas Detector is Integrated into the system. Working Temperature Range: 40ºF to +149ºF (-40ºC to +65ºC) Alarm Point: H2 Limited Explosive Line 20% (20% LEL). Once detecting H2 gas beyond the point, it will shut off the inlet valve to the H2 and heating elements automatically. |

Gas-outlet Flowmeter | One 0 -1000 ml/min floating meter is installed on gas-outlet end for adjusting gas flow rate. 1/4" Dia stainless steel tube is installed for burning hydrogen gas during gas flowing. One long lighter is included in the standard package for igniting hydrogen gas manually. Solenoid value automatically shuts down the gas inlet and heating elements in case of system failure.    |

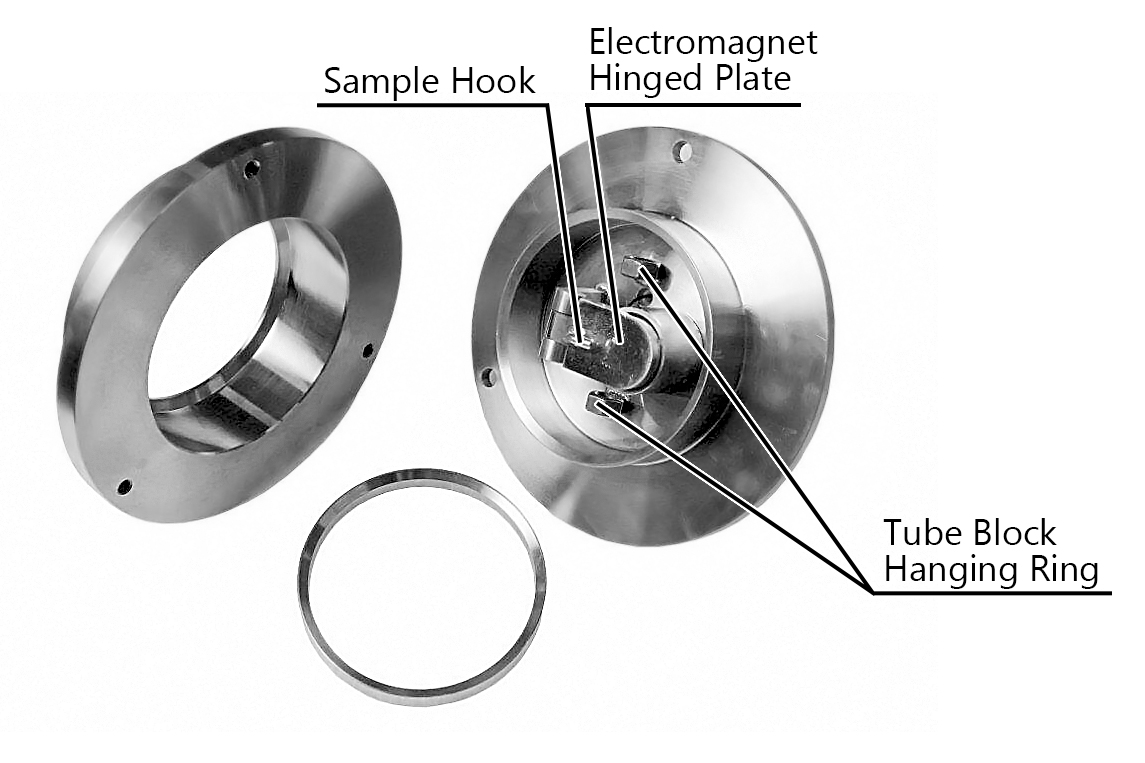

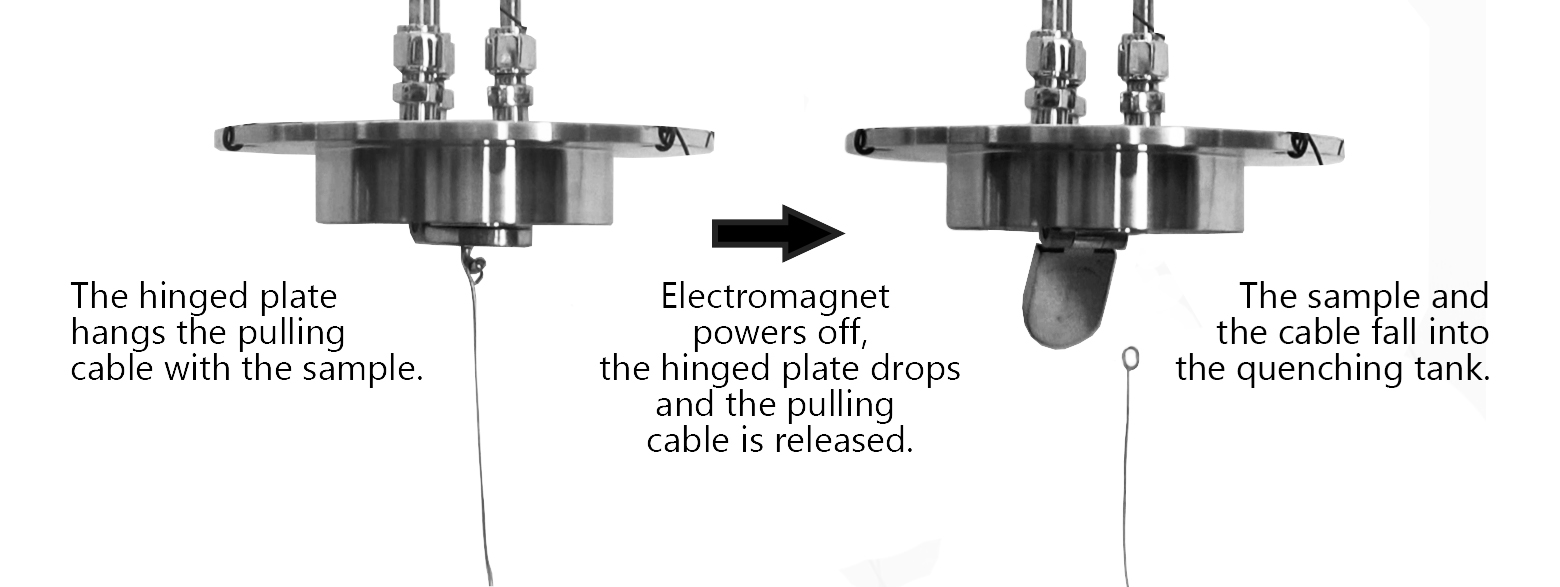

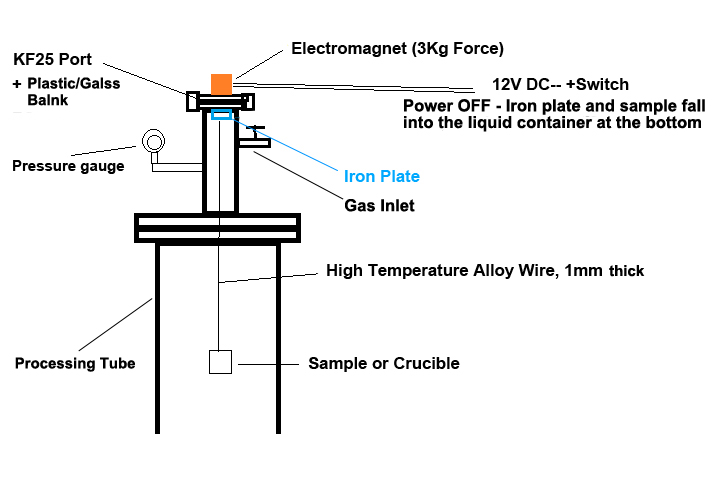

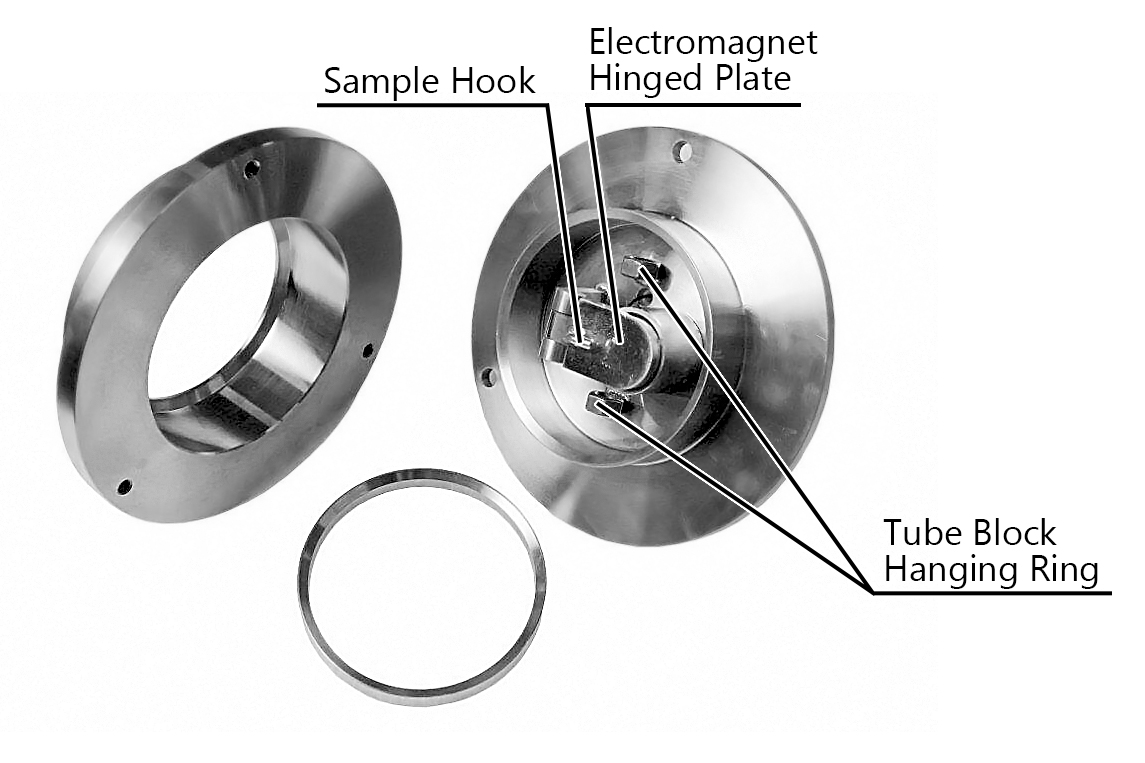

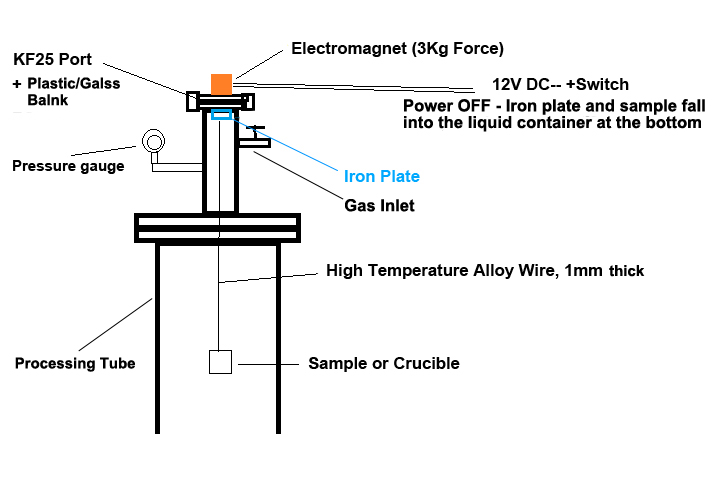

Electromagnet Sample Release Flange & Quenching

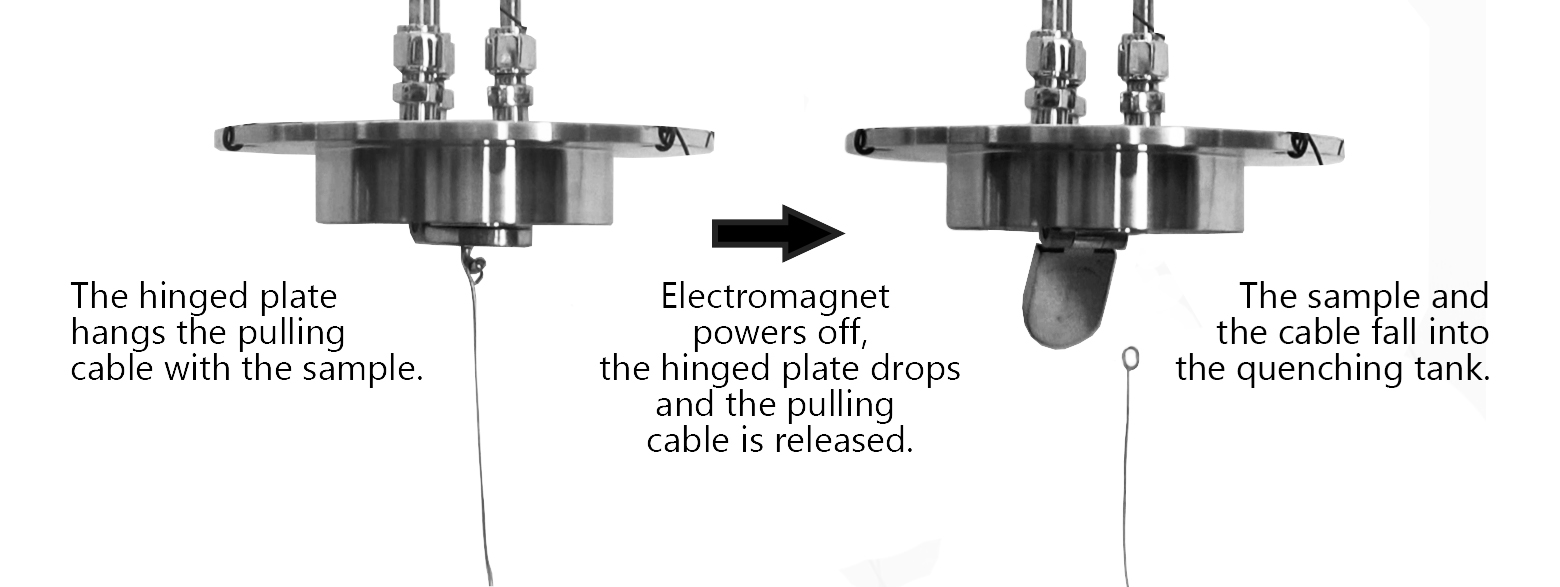

| - Full automatic electromagnet sample release flange

- Hinged plate hooks the cable, which pulls the sample.

- Hinged plate drops when the electromagnet powers off. The sample and the cable fall into the quenching tank.

- Rings are available for hanging the tube block with cables.

- Bottom flange is connected with a 4" gate valve ( manual operated ) via CF-100 adaptor

- The gate valve is connected with a quenching media container in size 400 x400 x 200 H ( mm )

- Caution: You must use ice water or cooled oil as a quenching agent if quenching under vacuum.

|  |  |  |  |  | | 1. Flange Structure | 2. Flange Operation | 3. Gate Valve | 4. Quenching Tank | 5. Quenching | 6. Pulling Cable |

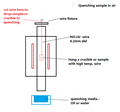

- Compared to electromagnet cable drop quenching, traditional approach (Cable Cut Quenching) consumes cables.

|  | | Trad. Quenching in Air | Trad. Quenching in Vacuum |

|

Gas Purification and Circulation

(Optional)

| - EQ-RMP-1 is an automatic recirculating moisture and oxygen purification system, which can provide an environment with moisture and oxygen concentration lower than 1 ppm for MTI's furnaces and gloveboxes.

- Two-columns of Molecular sieves are Built-in in the system. One is for removing oxygen and another is for removing moisture up to < 1 PPM

- The automatic pressure control system is built in to keep the pressure at a constant level

- 6" color PLC touch panel is included which can set and display the humidity and pressure level

- Oxygen sensors and moisture sensors are included.

|

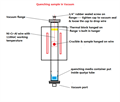

Hermetic Quenching Tank

(Optional) | - Hermetic quenching tank is optional for air-sensitive materials, which enables the entire quenching process under atmosphere control

- Please contact MTI for further inquires.

|

Vacuum Level | - 0.05 torr (Depends on the vacuum pump)

- Click Picture below to order vacuum pump separately

|

Heating Element | Fe-Cr-Al Alloy doped by Mo |

Dimension | 660L × 400 W × 1450 H (mm) |

Net Weight | ~85Kg (excluding mobile cart) |

Shipping weight | 500lbs |

Warranty | |

Laptop, software (Optional)

| - Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature profile, manage heat-treatment recipes, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

|

Compliance | - CE Certified

- All electric components ( >24V) are UL / MET / CSA certified

- NRTL or CSA certification is available at extra cost.

|

Application Notes

Click here to learn the installation of a gas regulator | - The flow rate for gasses should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

|

Operation Instructions | |