Furnace structure

| - Double layer flange with water cooling

- Total 24" heating zone length and 300 mm constant temperature zone.

- Two water cooling flange installed to keep the temperature low on the flange, water chiller needs to purchase separately. Please contact us for more information.

- High purity alumina fibrous insulation structure for max energy saving

- Hinged type flange for easy sample loading

|

| Input voltage | 208 - 240V AC Single phase |

| Power | 8kW (50Amps Air Breaker is required) |

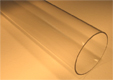

| Fused quartz tube size | - One quartz tube is included:279 O.D x 269 I.D x 1000mm Length (11" O.D x 10.6" I.D x 40" L)

- The tube can hold an 8" wafer boat, pls click the picture below to order quartz boat or flat sample order

Click here to choose a crucible Click here to choose a crucible |

| Heating element | NiCrAl Resistance Wire |

| Working Temperature | - Max. heating temperature: 1100°C (< 60min) ( under flowing inert gas without vacuum)

- Continuous working temperature: 400 -1000°C ( Under vacuum and flowing gas)

- Max. heating/cooling rate: 20°C/min

- Optional: If upgrade to GE 214 tube, Max. working temperature can reach 1150°C

|

| Heating zone | - Two heating zones, each zone 300mm ( 12" ) long

- Total heating zone length: 600mm (24'')

- constant temperature zone: 300mm at the center (with +/-1°C) ( if set up two zones at the same temperature )

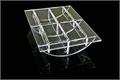

- Two foam ceramic blocks with alumina coating are included, which must be placed inside the tube as shown in the picture below (Optional quartz block is available at extra cost, please click here to order)

|

Temperature controller

| - Two Precision digital controllers with PID function and 30 segments programmable

- Secondary temperature monitor has the function of protection from over-temperature and broken T/C

- K type T/C

- Temperature accuracy: +/-1°C

- Software and PC interface module is available at extra cost

- The Eurotherm controller is available at the extra cost, which can reach +/- 0.1°C accuracy.

|

| Vacuum &Fitting Ports | - One pair of hinged type stainless steel vacuum seal flange with water cooling

- One mechanical gauge is included

- Two stainless steel needle valves & 1/4" hose fittings, KF25 vacuum port, and 1/4'' feedthrough. Vacuum pressure limit: depending on the vacuum pump. (Usually 10-2 torr by the mechanical pump, and 10-4 torr by the turbopump).

|

Water Chiller (Optional)

| - Cooling water is required.

- Please make sure the flow rate of cooling water is ≥ 10L/min, water temp. < 25ºC; pressure > 25 PSI.

- We suggest using the EQ-KJ5000 Series recirculating water chiller as a cooling system (please order separately here) to save water.

|

| Product dimension |  55"L x 27"W x 38" H mm 55"L x 27"W x 38" H mm |

| Net weight | 250Kg |

| Shipping dimension | 68" x 60" x 55" |

| Shipping weight | 350Kg |

| Warranty | One year limited warranty for the electronic and mechanical parts, excluding consumable parts such as heating elements and quartz tube. |

| Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipes, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000).

|

| Compliance | - CE Certified

- NRTL or CSA certification is available upon request at an extra cost

|

Application Notes

Click here to learn the installation of a gas regulator. | - Tube furnaces with quartz tubes are designed for use under vacuum and low pressure < 0.2 bar / 3 psi

- Vacuum pressures may only be safely used up to 1000°C.

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

|

| Operation Instructions & Video |   |

55"L x 27"W x 38" H mm

55"L x 27"W x 38" H mm