Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1100C Dual Zone High Pressure Vertical Furnace w/ Super-alloy Tube- OTF-1200X-HP-70-V

Description

OTF-1200X-HP-70-V is a high-pressure verticle split tube furnace with two heating zones. The processing tube is made of 70 mm OD. Ni-based superalloy with 1100oC max working temperature, which is designed for growing crystal via the high-pressure hydrothermal method. SPECIFICATIONS

| Working Pressure vs. Working Temperature |

|

| Working Gases |

|

| Heating Temp. |

|

| Heating Rate | ≤10°C/min |

| Heating Element | Fe-Cr-Al Alloy doped by Mo |

Heating Zone |

|

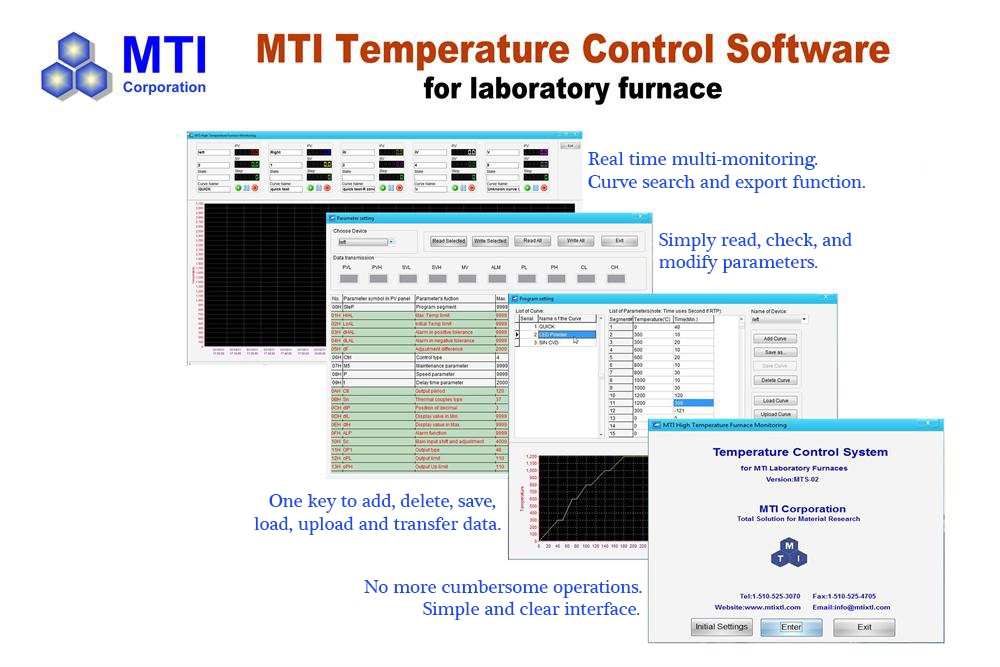

| Temperature Control |

|

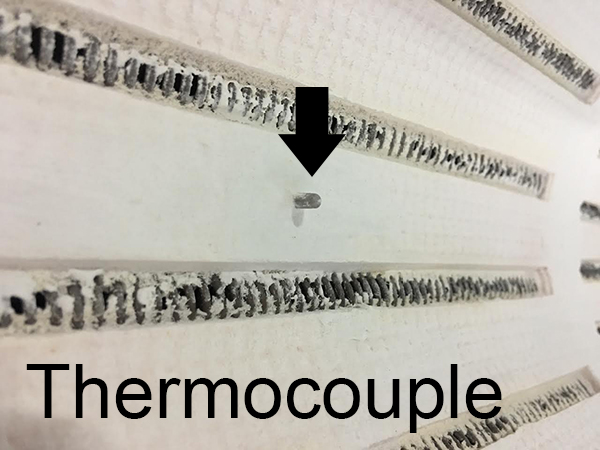

Thermocouple |

|

| Positive Pressure Sensor |

|

| Process Vessel |

|

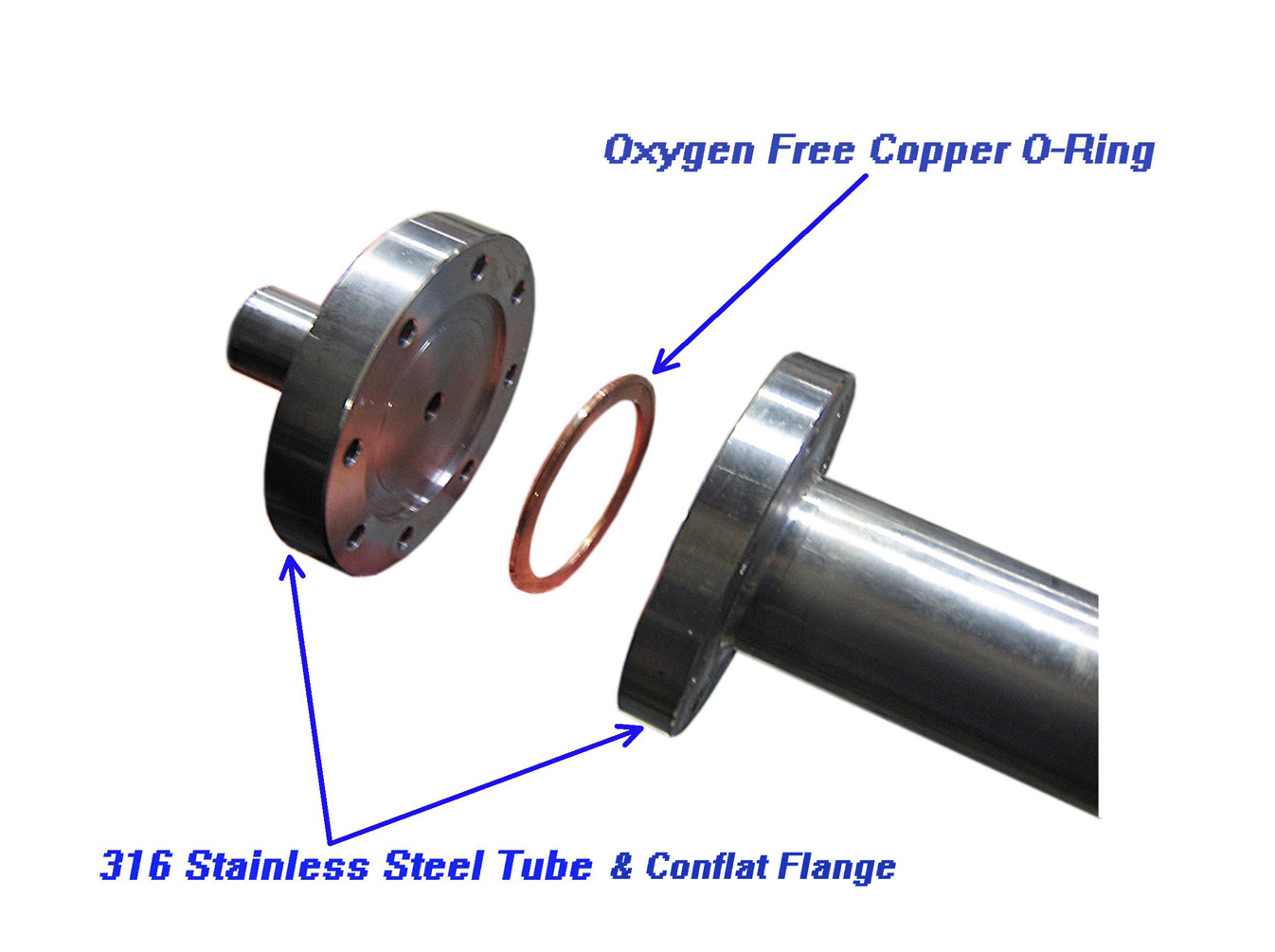

| Flange and Fitting |

|

| Optional Parts ( with extra cost ) |

|

| Voltage | AC 208 - 240V 50/60Hz |

| Power | 3 KW (20A breaker required) |

| Dimension |  900×600×1330 mm 900×600×1330 mm |

| Operation Instruction | |

| Application Notes |

|

Safety Notes  |

|