System Structure  | |

| Two-Zone Rotary Furnace | - Working temp: 1100ºC Max(<1hrs)., and 1000ºC for continuous heating.

- Two PID temperature controllers with 30 segments programmable.

- Input Power: 208 – 240 VAC, single phase at max. 1.5KW.

- High purity Alumina fibrous insulation for max. energy saving.

- Gear DC motor drives quartz tube with variable speed 2 - 10 RPM.

- Two zones: each zone length 4" (100 mm), total 8" (200 mm) heating zone.

|

Plasma RF Power Supply | - Output Power: 5 -300W adjustable with ± 5% stability.

- RF frequency: 13.56 MHz ±0.005% stability.

- Reflection Power: 100W max.

- Matching: Automatic.

- Power: 208-240VAC, Single Phase, 50Hz.

|

Evaporation Boat

| - Working temp: 1100ºC Max(<1hrs)., and 1000ºC for continuous heating

- 0.7ml alumina crucible with tungsten heating coil surrounded.

- K type thermocouple inserted for accurate temperature measurement of the source material.

- Working current: <= 30 A.

|

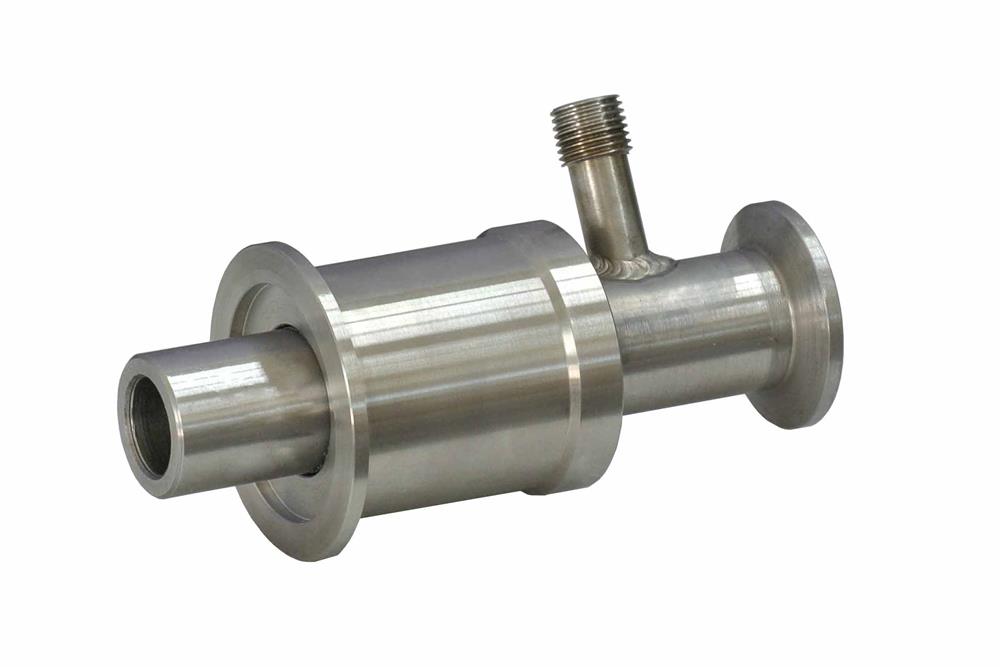

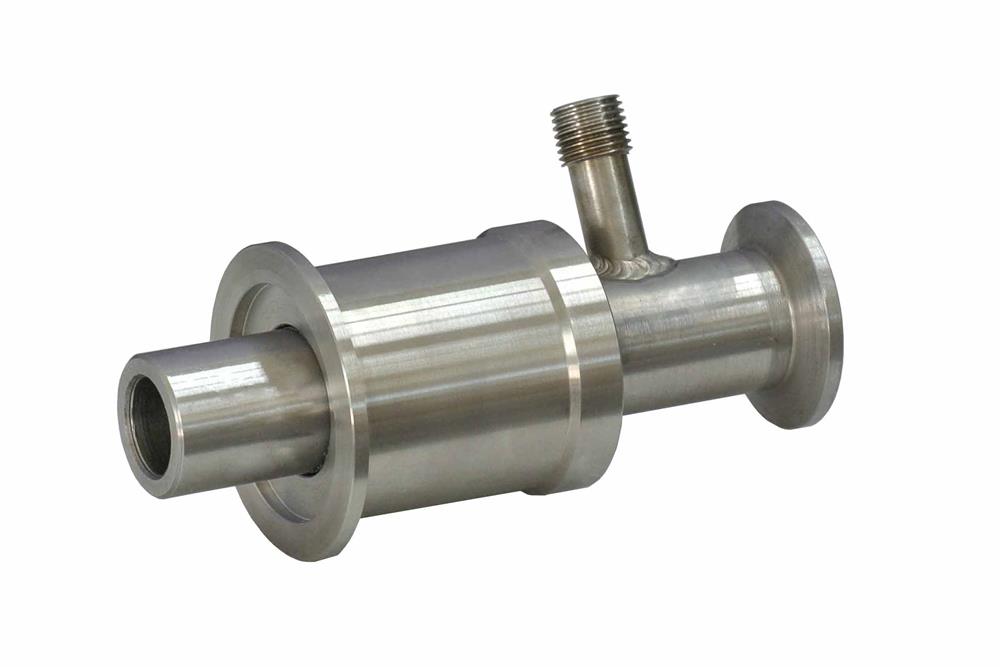

Sealing Flanges  | - Standard: 2'' O.D Fused quartz processing tube, please click the pic on the left for details.

- One pair of 1'' SS sealing flange with rotatable gas connector needle valves and are included for immediate use.

|

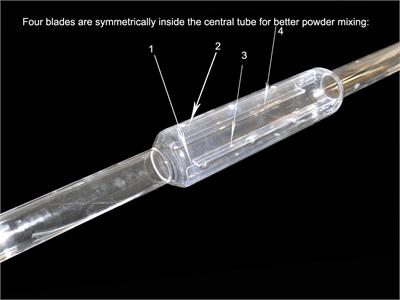

Sealing Flanges  | - A pair of 1'' O.D quick disconnect flange with KF25 port are installed on each end of the tube.

- Magnetic fluid seal swivel coupling is used to enable the tube rotation without twisting the fireline or downstream attachments (such as gas, powder, and electrical delivery lines).

|

Tube Rotation Speed | |

Vacuum Pump & Gauge | |

MFC Gas Mixing Station | - Four precision mass flow meters (0.02% accuracy) with digital displays are installed on the bottom case to control the gas flow rate automatically.

- MFC 1: Gas flow range from 0~100 SCCM

- MFC 2&3: Control range from 0~200 SCCM

- MFC 4: Control range from 0~500 SCCM

- Gas inlet/outlet fittings: 6mm O.D tube fitting

- Power: 208-240VAC 50/60Hz

- Stainless steel needle valves for manually ON/OFF control of gas supply.

- Large PLC touch screen control enables easy flow rate settings

|

| - Two heating zone design with an individual temperature controller.

- Precise PID control of heating, cooling rate, and dwell time, 30 programmable segments.

- Built-in overheating & broken thermocouple protection.

- Over-temperature protection and alarm allow for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

- Three K-type thermocouples (one for each zone).

- RS485 Communications Port.

- Optional:

- The furnace may be operated by PC by installing a control module. Please order an MTS-02 control module at extra cost.

- If you order the PC control module together with the furnace, we will install and test it before shipping. We recommend you to order a computer laptop from us to avoid software installation problems. For more information please click here.

|

Dimensions & Weight  | - Furnace: 1400mm L x 600mm W x 1250mm H (with lid opened); Gas Mixing Station: 600mm L x 850mm W x 700mm H

- Net weight: 400 Lbs.

- Shipping Weight: 500lbs.

|

Warranty | One year limited warranty with lifetime support (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order replacements at related products below). |

Volumetric Feeder and Collector Tank (Optional)   pic. 1 pic.2 | - EQ-PF-1S automatic feeder includes a motor-driven agitator and stainless steel hopper with a built-in vibrator. It is designed for feeding solid powder into a furnace for continuous firing/heat treating. Please click the pic.1 on the left to order.

- Stainless steel collection tank ( 2 Liter Capacity ) can be installed on the other end of processing tube to gather the fired powder without exposure to air. Please click the pic.2 on the left to see details.

- Note: contact us for customization details.

|

Laptop, software & WiFi Control (Optional)   | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables a user to edit temperature profile, manage heat-treatment recipe, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000).

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance  | - CE Certified

- NRTL or CSA certification is available at extra cost. (pls click marks below to learn details )

|

Application Notes

| - The tube furnaces with mullite tube are designed for use under vacuum and low pressure < 0.02 Mpa (Relative)

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Never heat the furnace while the gas release valve is closed.

- The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

|

Operation Instructions | |