| Structure | |

| Working Pressure Vs Temp. | - 200 bar Max. at 650 °C

- 140 bar Max. at 800 °C

- 80 bar Max. at 900 °C

- 50bar Max. at 1000 °C

- 2.5 bar Max. at 1100 °C

- 1.2 Bar Max. at 1150 °C

- Never heat up above 1200°C

|

Working Gases | - Inert gas or oxygen

- No hydrogen or any flammable gas is allowed

|

| Heating Temperature | - 1100 °C max.for < 1 hour

- ≤ 1000 °C continuous

|

| Heating Rate | - 0 – 200 °C: ≤ 10 °C/min

- 200 – 700 °C: ≤ 6 °C/min

- 700 – 900 °C: ≤ 3 °C/min

- 900 – 1100 °C: ≤ 1 °C/min

|

| Cooling Rate | - 1100 – 800 °C: ≤ 5 °C/min

- 800 – 200 °C: ≤ 10 °C/min

- 200 – 0 °C: free cooling

|

| Heating Zone | - Three heating zones: 150 mm + 150 mm + 150 mm

- Total heating zone length: 450 mm

- Constant temp. zone: 280 mm ±1°C

|

Temperature Gradient

| - The furnace is able to achieve a temperature gradient up to 19 °C/inch (150 °C / 200 mm), if

- The Center zone is heated up to 1000 °C

- Left and right zones remain idle

|

| Heating Element | - Fe-Cr-Al Alloy doped by Mo

|

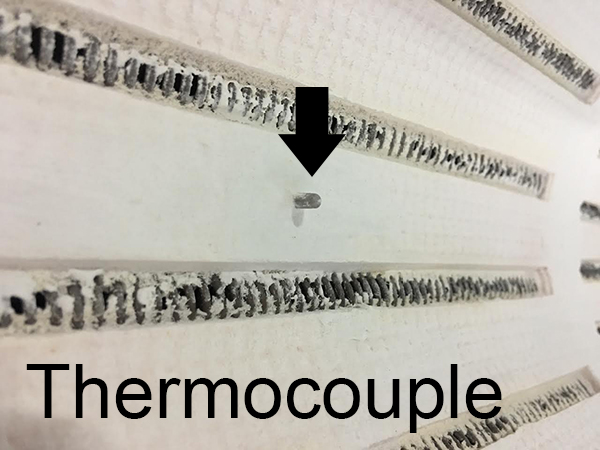

| Thermocouple | |

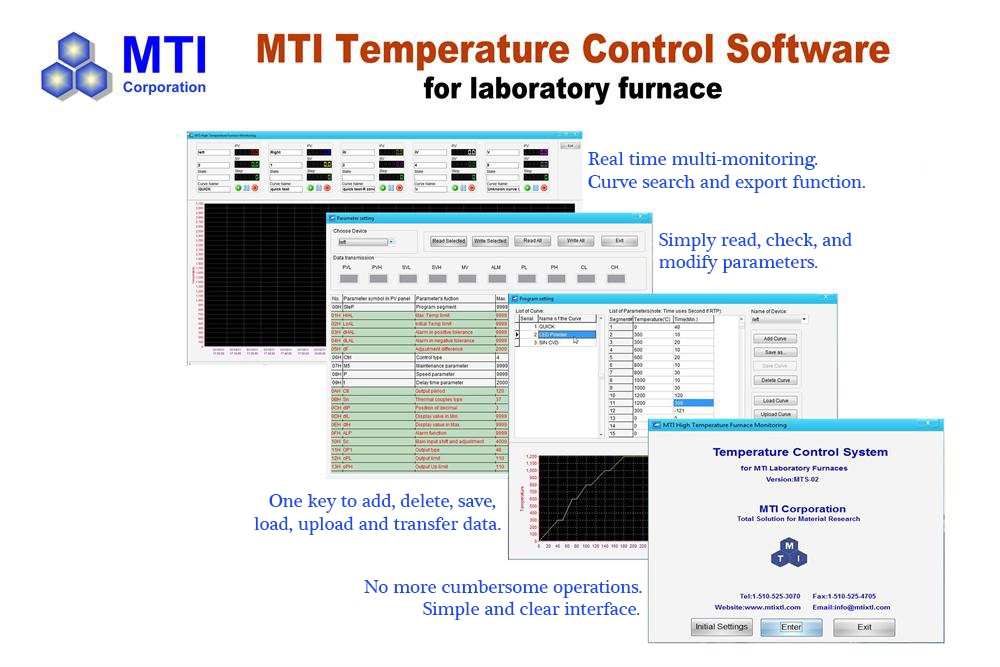

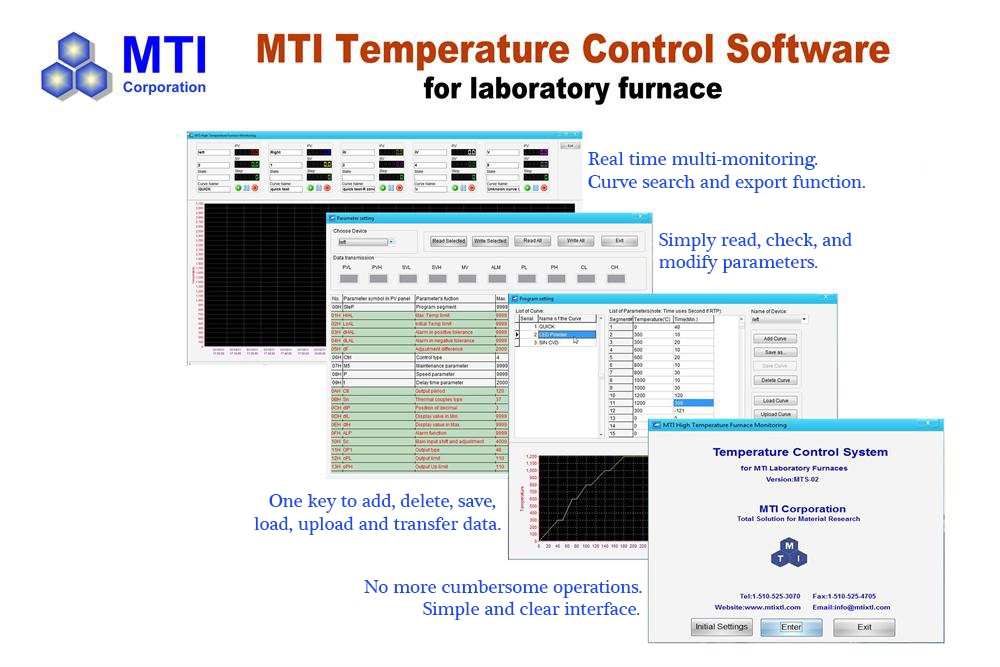

| Temperature Control | - Three precision digital temperature controllers with 30 programmable segments and +/- 1 ºC accuracy

- Safety protection of over-temperature and broken thermocouples are integrated

- PC control software is available at an extra cost

- Eurotherm 3000 controller with +/-0.1°C accuracy is available upon request at the extra cost.

|

| Process Vessel | - Made of Nickel-based superalloy GH747(Click to download GH747 nickel-based alloy datasheet)

- Size: 85 mm OD x 50 mm ID x 1000 mm L

- Working gasses: O2 and inert gasses such as N2, Ar, and He

- Small quartz or alumina boat should be used to load the sample inside the tube. Never place the sample directly onto the tube without a crucible, which may greatly shorten the processing tube service-life

- Warning: Never put the sample inside the tube directly without crucible or isolated foil to avoid sample react with tube alloy.

- You may use gold or nickel foil to wrap the crucible to minimize the contamination to the pressure vessel.

- Attention: The processing tube is consumable. Pls click the photo below to order a spare one

|

Pressure Sensor and Valve

| - A pressure gauge with a range of 0 – 25 MPa and an over-pressure alarm is installed (downstream side)

- A pressure control valve with a working range of 0.2 – 15 MPa is installed (the upstream side with a 1/4" BSPP venting port)

- If the measured pressure reaches the high-pressure alarm value, the pressure control valve will be opened until the pressure drops 0.2 MPa (2 bars) below the alarm value

- The manual pressure relief valve is installed for manual pressure control and relief (the downstream side with 1/4" BSPP gas outlet port)

|

High-pressure relief valve

| - A safety pressure relief valve is recommended (the upstream side with 1/4" NPT venting port)

- Please info us of your application temperature and we will pre-set the release pressure for you. For example, you need to heat to 800C, the Max working pressure should be 140 bars, we will pre-set the relief valve to 140 bars.

|

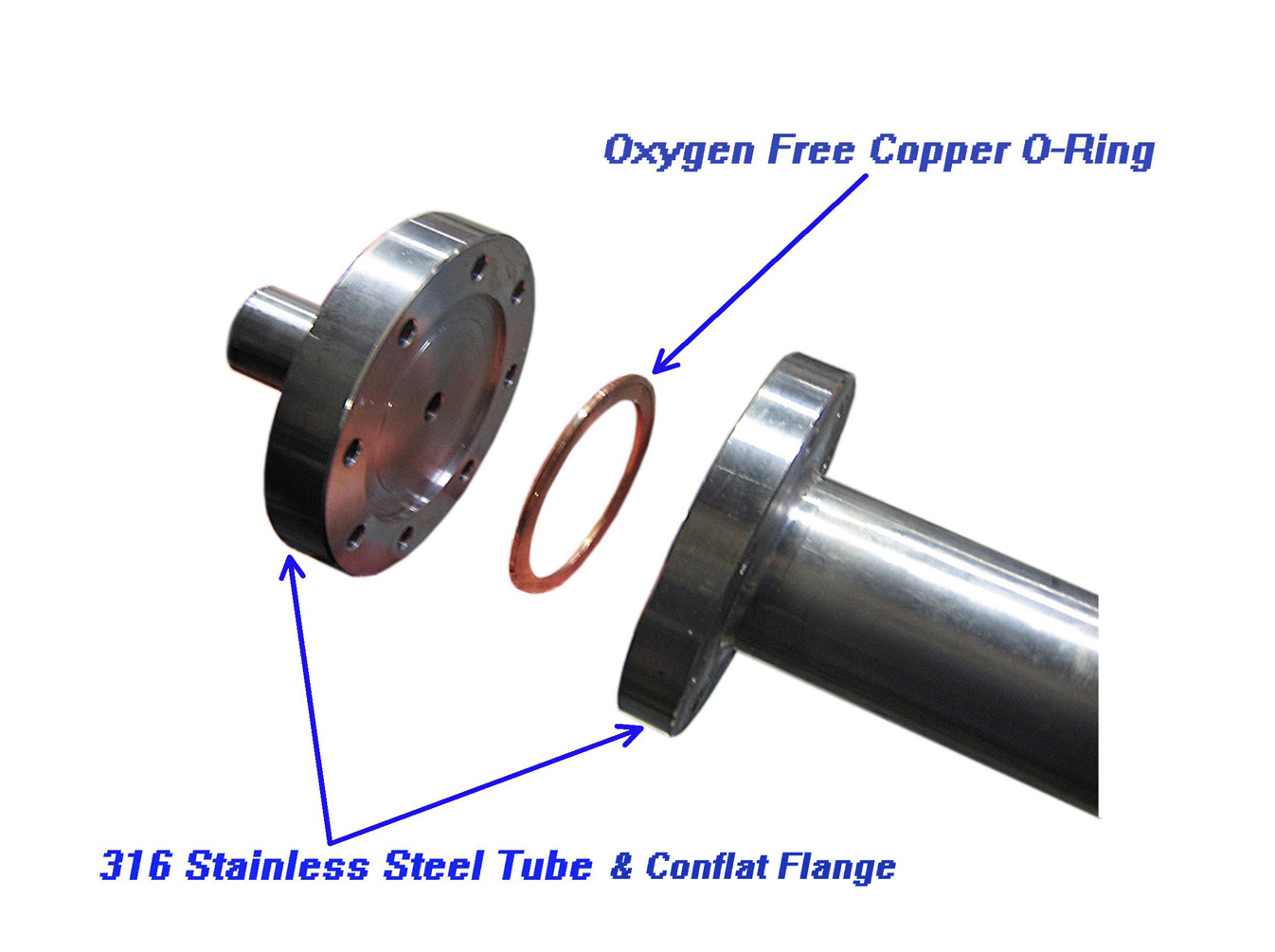

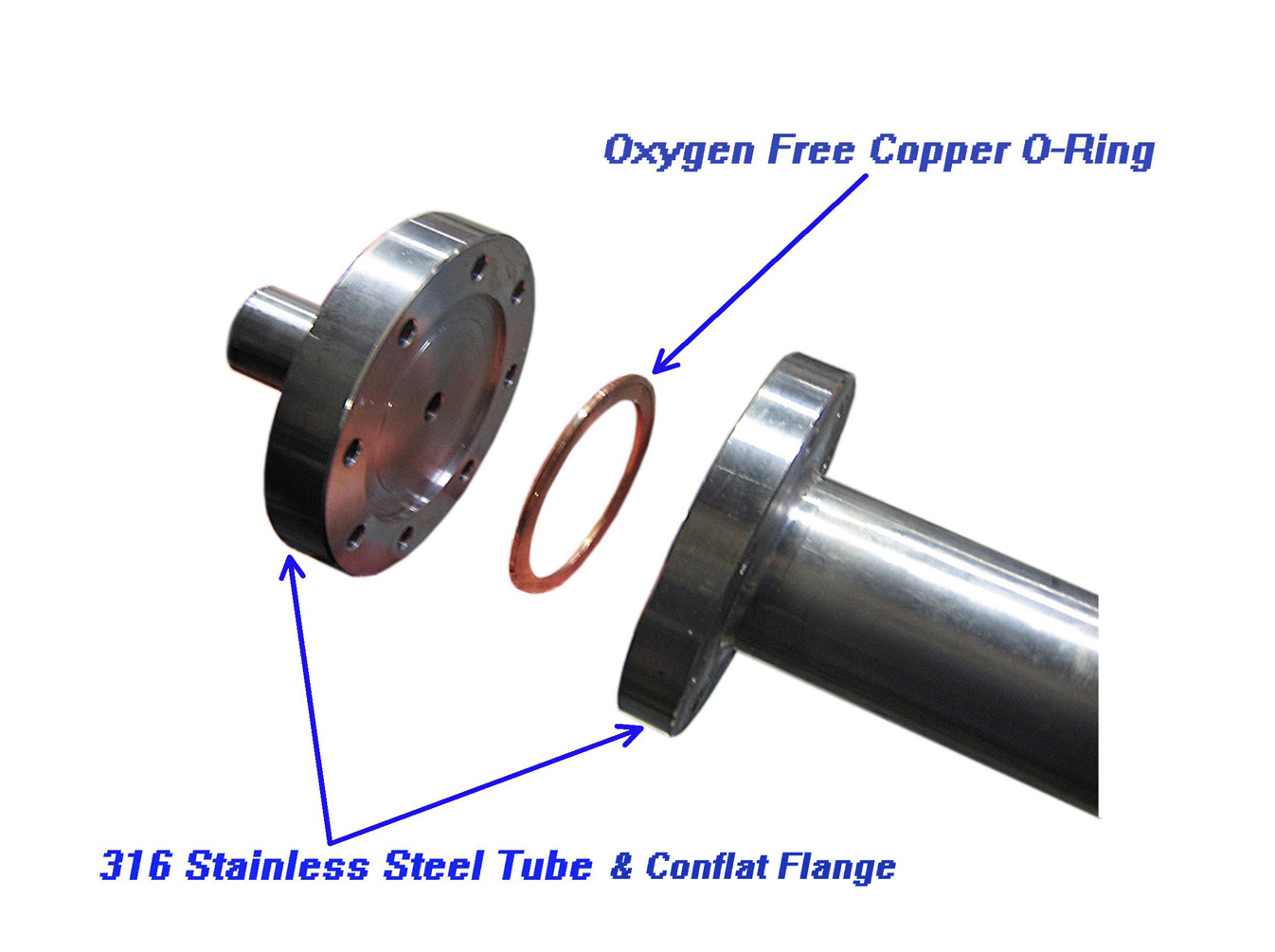

| Flange and Fitting | - A pair of 63 mm CF-type flanges are included. Please use a torque wrench (optional, not included) to avoid over-tightening the flange bolts.

- 2 pieces of copper O-rings (99 mm OD x 82 mm ID x 2.2 mm thickness) are included. Please order extra copper O-rings as consumable parts

- A pair of cooling fans are included for air cooling the flanges

- One mobile cart with installation holes is included for easy setup and immediate use

|

Optional Parts

(with extra cost) | - Please order heavy-duty rotary vane vacuum pump EQ-YTP-50 for low vacuum operation (Pic #1)

- If a high vacuum is needed, please use the turbopump station – EQ-PV-HVS2 (Pic. #2), which can reach 10-6 torr vacuum

- Gas flow control system is available upon request (Pic. #3)

- Please use a torque wrench (optional, not included) to avoid over tightening the flange bolts (Pic. #4)

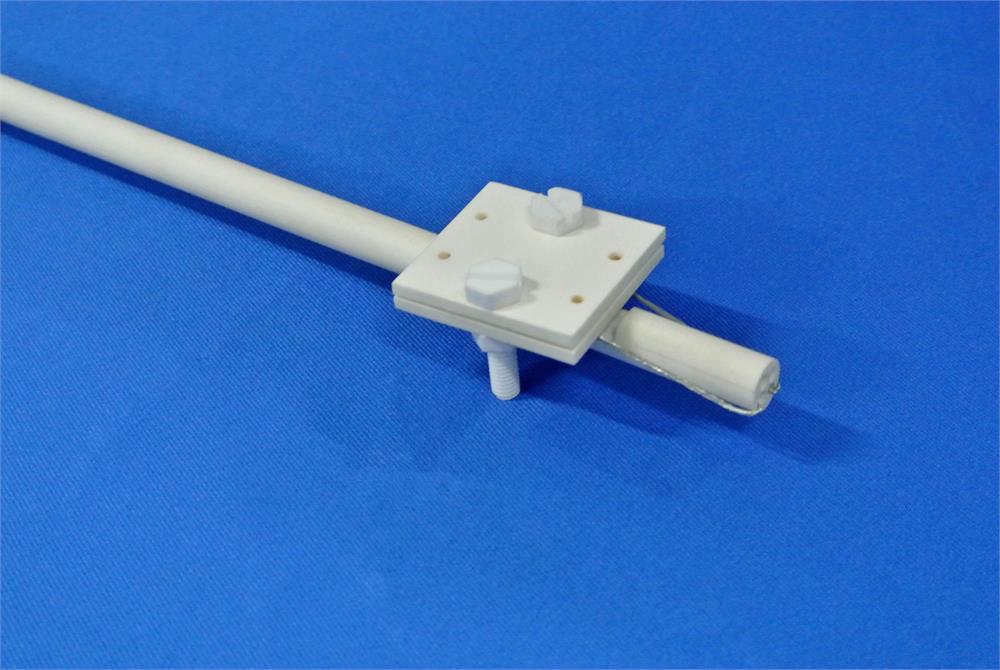

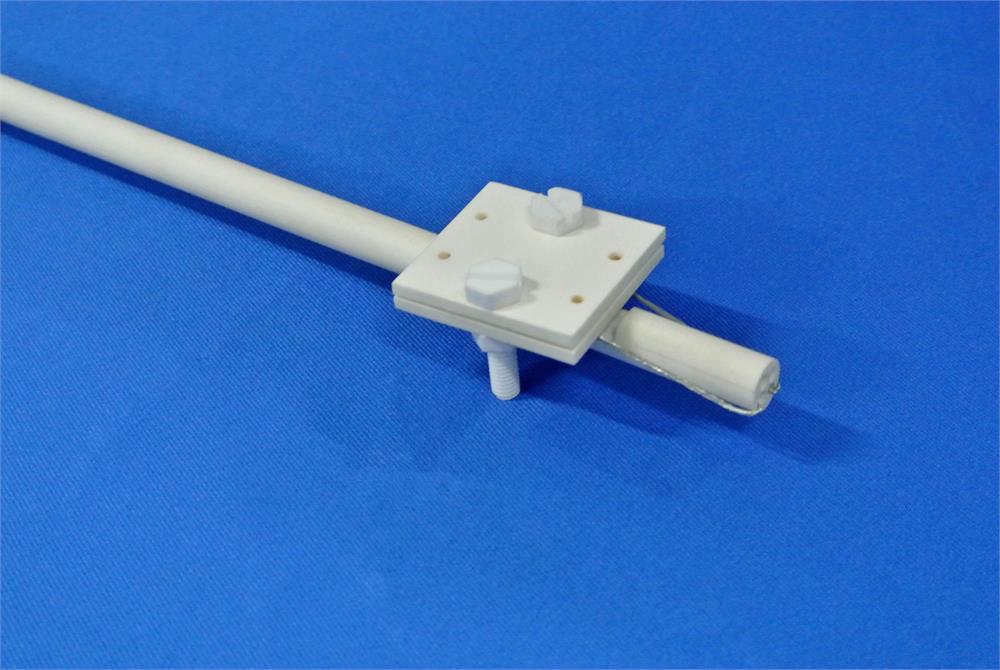

- To measure the electric properties of thermoelectric ceramics under high pressure & high temperature, please order alumina fixture and high-pressure electrical feedthrough (10 MPa max) with the furnace at extra cost (Pic. #5 & #6)

1 1 2 2  3 3  4 4  5 5  6 6 |

| Power | - AC 208 - 240V 50/60Hz, single phase

- 4.2 KW (32 A breaker required)

|

| Operation Instruction |   |

Compliance and Warranty

| - CE certified

- NRTL or CSA certification is available upon request at the extra cost.

- One year limited warranty for lifetime support

|

Safety Notes

| - Ni-based Superalloy ( Waspaloy or equivalent) is a reliable processing tube, which has excellent ductility and tensile property so only creep deformation happens under overpressure before a cracking.

- Please see pics left to see Ni-based Super-alloy ( Waspaloy or equivalent) processing tube under overpressure test

- Attention: For the use of flammable, toxic, or corrosive gases, you must contact the MTI engineering group for a consultation to know all the prerequisites and precautionary measures.

|

1

1 2

2  3

3  4

4  5

5  6

6