Furnace

| - Splitable Three heating zone tube furnace with air cooling layer

- High quality fibrous insulation and reflective coating for max. energy saving.

- Power: 208 - 240VAC 50/60Hz , 4KW max.

|

| Heating Zone | - Three heating zones: 150mm + 150mm + 150 mm

- Total heating zone length: 450mm

- Constant temp. zone: 300mm ±5°C

|

| Working Temperature | - 1100°C max.for < 1hr

- 1000°C for continuous

- Heating rate: ≤10°C/min

|

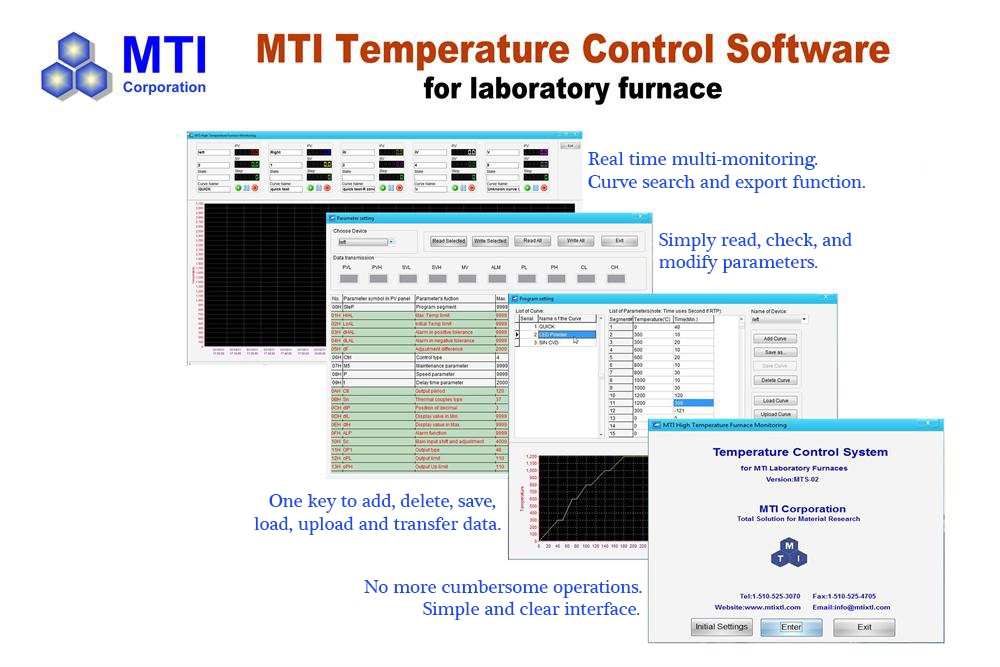

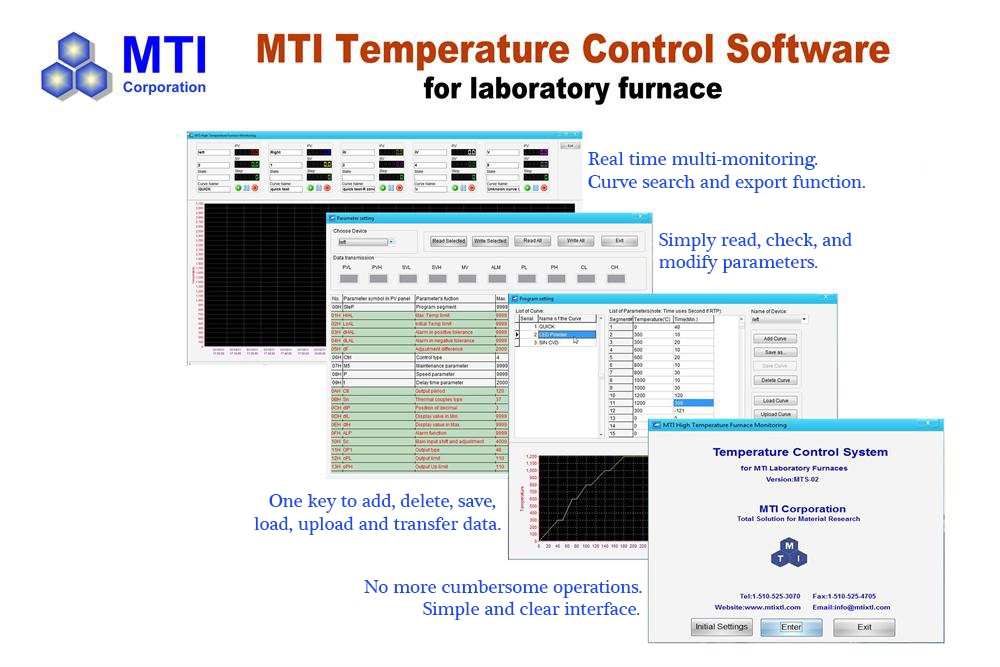

| Temperature Control | - Three precision digital temperature controller with 30 segments programmable

- PID control method with the protection of over-temp. and a thermal couple broke

- Temperature stability: ±1°C

- PC control software and laptop computer are included for PC operation

|

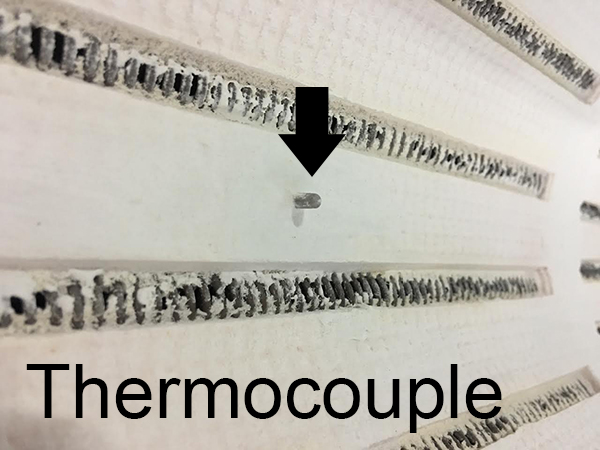

Thermocouple

| |

Process Vessel &

Safety Frame  | - The pressure vessel is made of Nickel-based superalloy GH747 (Click to download GH747 nickel-based alloy datasheet)

- Vessel size: OD 85 x ID 50 x Length 1000 (mm)

- The pressure vessel is located inside a steel frame to avoid flange flying out by accident ( see picture below ) and ensure safe operation.

- Optional: torque wrench is available here to avoid over-tighten the flange bolts.

- Warning: Never put a sample inside tube directly without crucible or isolated foil to avoid sample react with tube alloy.

|

| Working Pressure vs. Working Temperature | - 140 Bar max. at 800°C

- 80 Bar max. at 900°C

- 40 Bar max. at 1000°C

- 2.5 Bar max. at 1100°C

- 1.2 Bar Max. at 1150 °C

- Never heat up above 1200°C

|

| Working Gases | - Inert gas and oxygen

- No hydrogen or any flammable gas

|

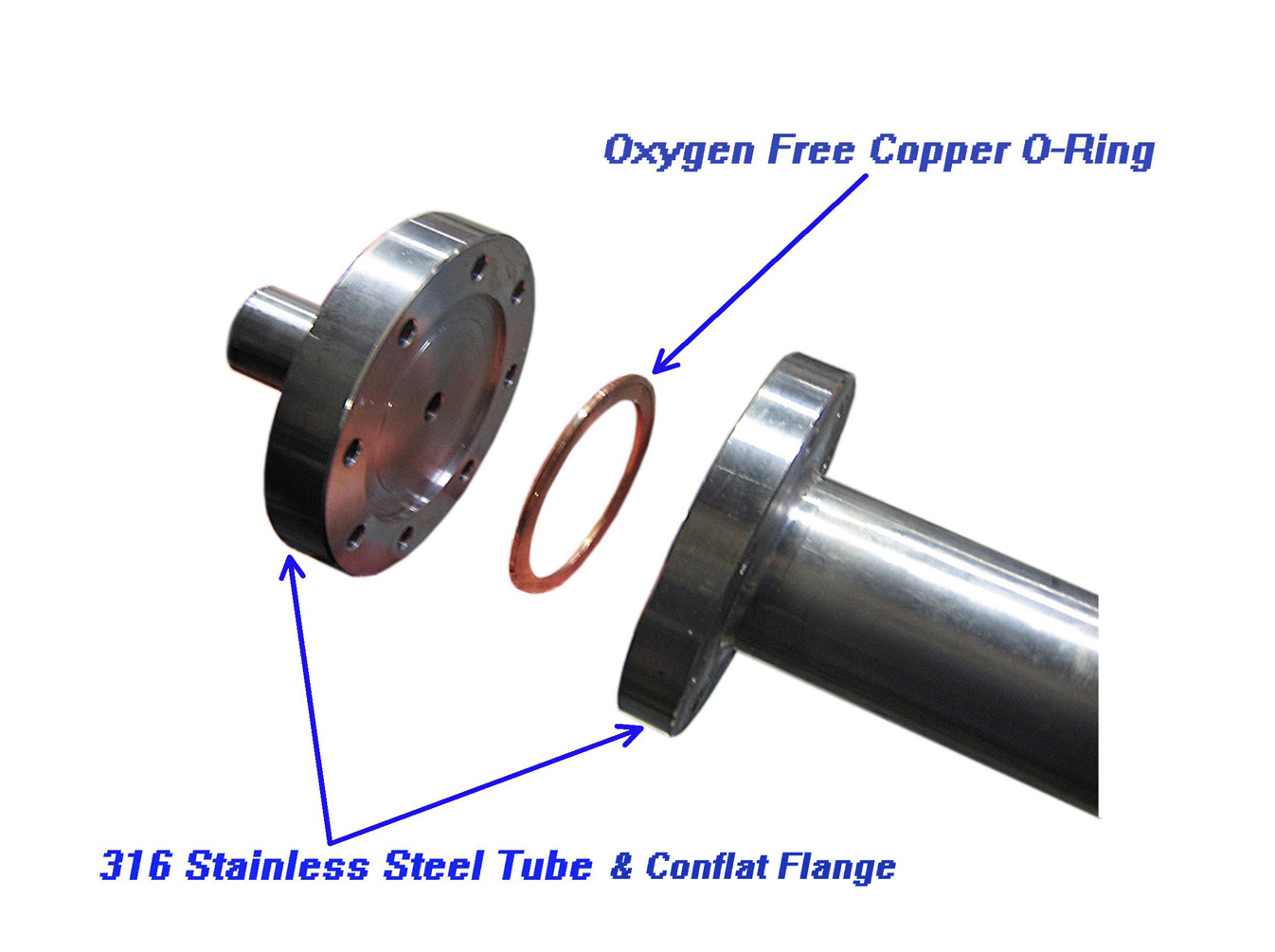

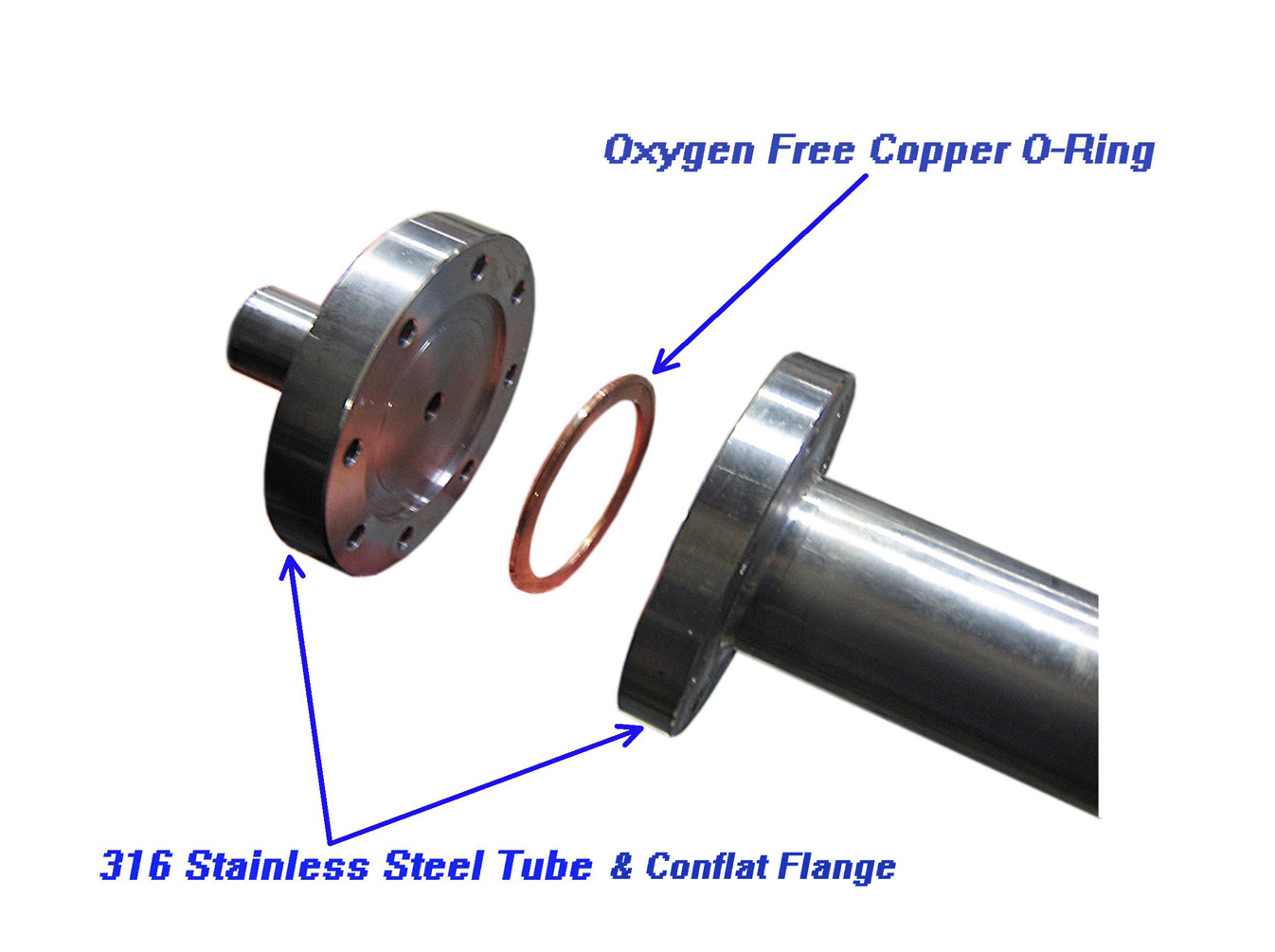

| Flange and Fitting | - Two CF type flanges are weld with female 1/4"NPT fitting to connect the high-pressure tube

- 2 pcs Copper o-rings are included ( spare copper O-ring is available as consumable )

- One pair of water cooling ring, made of copper tube, is installed on two ends of the tube ( > 16 liters/min water flow is required)

- One 16L/min flow rate recirculating water chiller is included as a cooling system to save water.

|

| Gas Flow System

| - The gas control system is built in a heavy-duty mobile table under furnace and safety frame

- Three pressure sensors and digital displays are installed to monitor furnace pressure for gas inlet, inside tube and gas flow end separately

- One high-pressure mass flow controller is a built-in gas outlet to control gas flow rate with max. 10Mpa working pressure and 500 MCC flow rate laptop via included software for remote monitoring and controlling

- Three adjustable pressure release valves are installed to ensure safety. The valve will release gas when the pressure reaches the setting point.

|

| Dimension & Weight | - Dimension: 1200 L x 600 D x 1540 H,mm ( includes furnace, pressure control table and safety frame

- Net weight: 180 kg

|

| Operation Instruction |  |

Compliance and Warranty

| - CE certified

- NRTL or CSA certification is available upon request at the extra cost.

- One year limited warranty for lifetime support

|

| Application Notes | - Hytort Application, or named Hydroretorting of Shale Oil is a process developed by IGT to double the yield of shale oil and hydrocarbon gases. MTI High-Pressure furnaces with Ni-based superalloy tube is an ideal tool for conducting related experiments. Please click underlined to view research paper.

|

| Safety Notes | - Ni-based Superalloy ( Waspaloy or equivalent) is a reliable processing tube which can be used under high temperature and high pressure.. It has excellent ductility and tensile property so only creep deformation happens under overpressure destruction test and following by a crack formed (usually at the hot zone at the center of tube) to release the pressure. Brittle fracture won’t happen in the overpressure destruction test which means no tube explosion will happen under overpressure of inert gas or safe gas or under other accidents causing overpressure of inert gas or safe gas.

The pics show Ni-based Super-alloy processing tube under overpressure test The pics show Ni-based Super-alloy processing tube under overpressure test

- Warning:

- Never put a sample inside the tube directly without crucible or isolated foil

- For the use of flammable, toxic, or corrosive gases, you must contact the MTI engineering group for the consultation to know all the prerequisites and precautionary measures.

- A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Please click here to learn how to install the gas regulator.

|

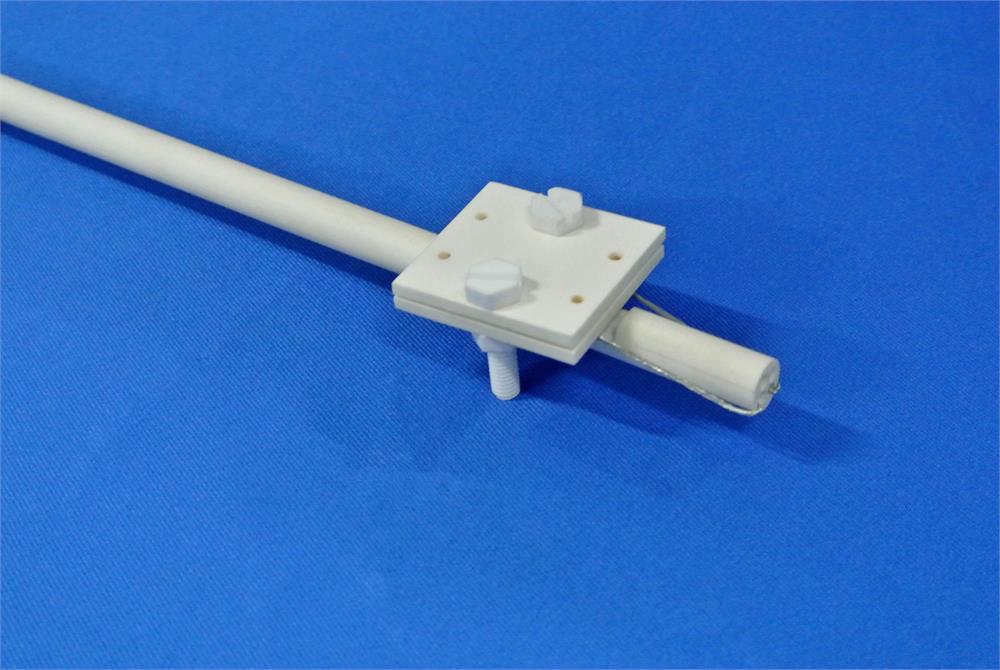

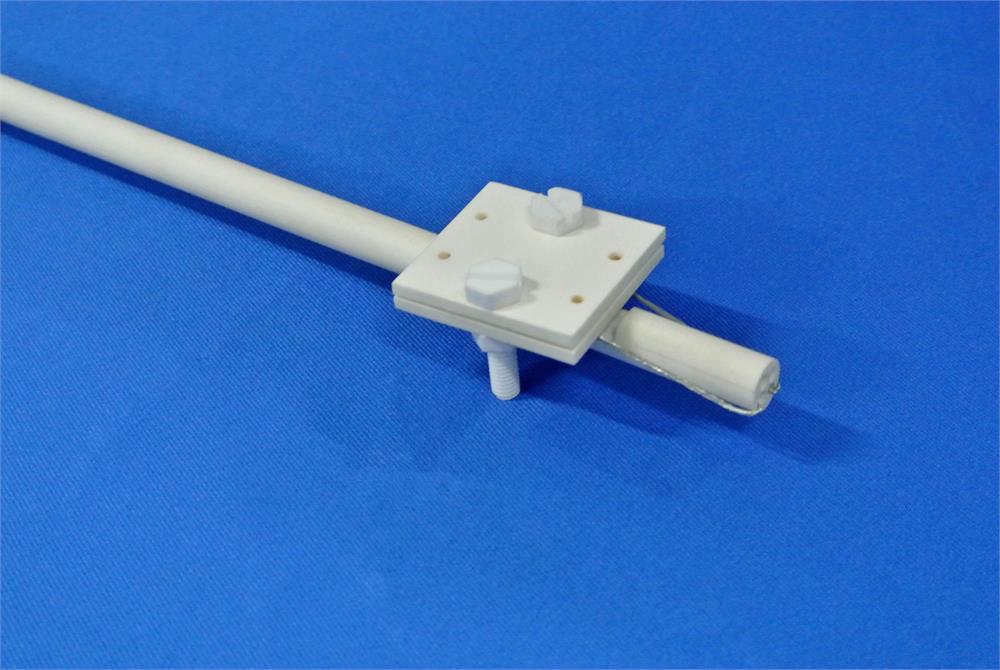

| Optional Accessories | - To measure the electric properties of thermoelectric ceramics under high pressure & temperature conditions, please order alumina testing fixture and high-pressure electrical feedthrough (10Mpa Max.) with the furnace (additional fee will apply).

|

The pics show Ni-based Super-alloy processing tube under overpressure test

The pics show Ni-based Super-alloy processing tube under overpressure test