| - One high thermal conductivity Alumina flat sample holder (2" Lx1"W) is fixed on K type sample, and the thermal couple with the sample holder can be moved inside quartz tube driven by a magnet manually to find desirable temperature position inside the tube for evaporation or deposition.

- One NIST certified precision temperature monitor is connected to thermal couple and sample holder via feedthrough on the vacuum flange.

- One magnet is embedded inside the thermal block, and another magnet is placed outside the tube. move the outside magnet can move the sample holder with the thermal couple inside the tube in or out

- 30 segment programmable temperature controller is installed in furnace to set up Max. working temperature up to 1200oC at the center of the furnace

- One small quartz crucible is included, which can be used to contain evaporation material, or please wafer on top for deposition based on your application.

|

Furnace Power | - 110VAC or 208 - 240 VAC, 50/60Hz (Please confirm voltage when place order )

- 1.5 KW

|

Max. Temperature | 1200°C (<1 hour) |

Continuous Temperature | 1100°C ( continuous) |

Max. Heating Rate | <= 20 °C/min |

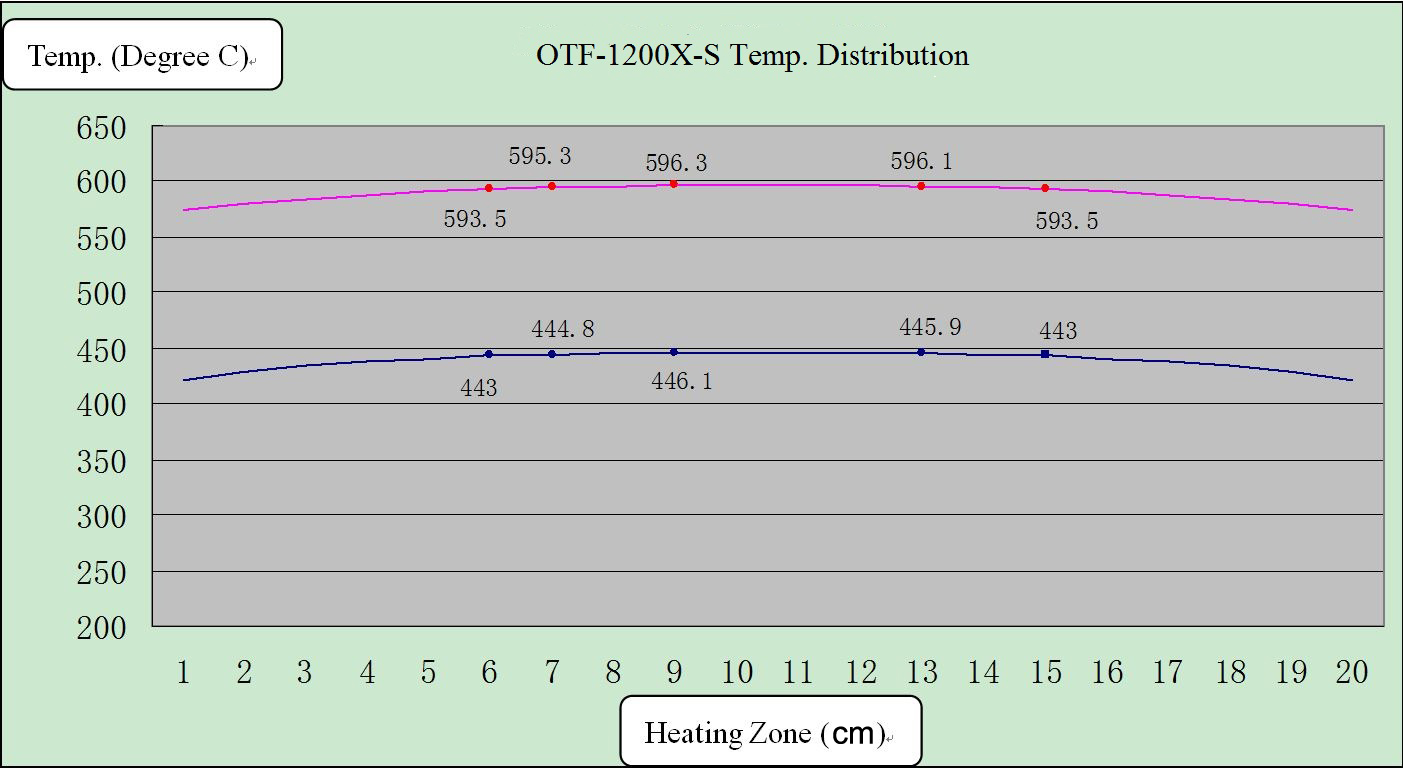

Heating Zone  | - Heating Zone Length: 8" (200mm), single zone. The following picture shows the temp. distribution across the heating zone, please click to enlarge.

- Constant Temp. Zone: 2.3" (60mm) (+/-1°C) @ 1000 °C

- You shall measure the furnace temperature profile for your own application before making film growth.

|

Temperature Controller   | |

Temperature Accuracy | +/- 1°C |

Heating Elements | Fe-Cr-Al Alloy doped by Mo |

Tube Size | |

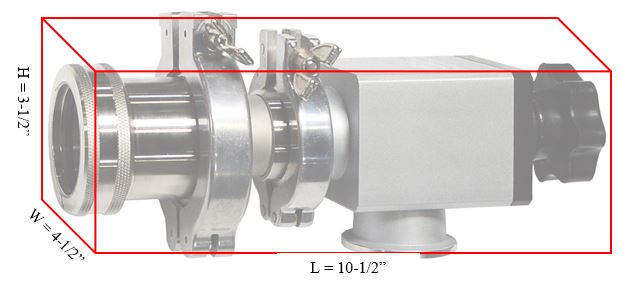

Vacuum Flanges  | 2" default flange with 1/4'' Bard fittings, 1/4'' tube feedthrough port (for 1/4" O.D thermocouple insert) and a KF25 vacuum port(click picture below to see details ) |

Vacuum Level | 10-2torr (by mechanical pump) |

Fitting Ports

&

Optional Parts | - You may need a vacuum valve at the end of vacuum port ( click picture left to order )

- You may consider ordering quick connecting flange at extra cost.

- You may order a multi-channel gas delivery system for DVD or CVD operation.

-

|

Dimensions  | With lid close: 1055mm (L) × 300mm(W) × 400mm(H)

With lid open: 1055mm (L) × 300mm(W) × 560mm(H) |

Net Weight | 22 Kg |

Shipping Package Size | 48''(L) x 24''(W) x 28''(H) |

Shipping Weight | 120 lbs |

Warranty | One year limited warranty with lift time support (Consumable parts such as processing tubes and O-rings are not covered by the warranty. |

Laptop, software & WiFi Control(Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipes, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance | - CE Certified

- NRTL or CSA certification is available at extra cost. ( please click marks below to learn details )

|

Application Notes

Click here to learn the installation of a gas regulator | |

| Operation Instructions |    |