Phone(+65) 6284 3818 |

sales@premier-sols.com |

Enquriy |

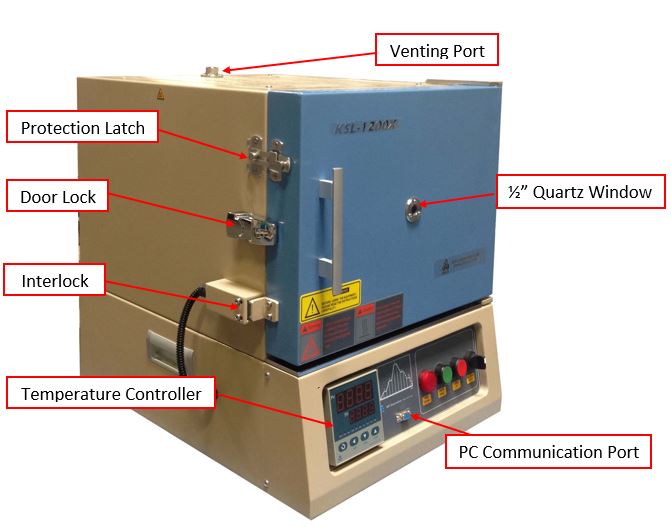

1200C Hybrid Furnace (12x8x5", 7.2L), Dual 2” Tube / Muffle 3-In-1 - KSL-1200X-H-UL

Description

KSL-1200X-H-UL is a newly designed hybrid tube/muffle furnace, which is built with two 2“ quartz processing tubes with a vacuum flange and one 7.2L box chamber. The furnace can process different samples at the time under various atmospheres. It is the most cost-effective furnace for material research.

KSL-1200X-H-UL is a newly designed hybrid tube/muffle furnace, which is built with two 2“ quartz processing tubes with a vacuum flange and one 7.2L box chamber. The furnace can process different samples at the time under various atmospheres. It is the most cost-effective furnace for material research.

SPECIFICATIONS

|

|||||||||||||||

| Muffle/Tube Hybrid Furnace |

|

||||||||||||||

| Vacuum Flange & Optional |

|

||||||||||||||

|

Chamber Dimensions

|

|

||||||||||||||

| Power | 3.5KW | ||||||||||||||

| Voltage | 208 -240V Single Phase 50/60 Hz Note: Power cable included without a plug. Please install a plug by yourself or click the link below the picture to choose a plug according to your country or your lab requirement |

||||||||||||||

| Maximum Working Temp | 1200°C Max continuously | ||||||||||||||

| Stability at 1000 °C | +/- 0.5 ° C | ||||||||||||||

| Uniformity at 1000 °C | +/- 2.0 °C | ||||||||||||||

| Max. Heating Rate | 30°C/ min. | ||||||||||||||

Temperature Controller |

|

||||||||||||||

|

|||||||||||||||

| Net Weight | 150 Lbs | ||||||||||||||

| Shipping Weight & Dimensions |

|

||||||||||||||

Dimensions |

|

||||||||||||||

| Warranty |

|

||||||||||||||

| Compliance |

|

||||||||||||||

| Application Notes |

|

||||||||||||||

| Operation Instructions |  |