Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1200C Max. Ultrasonic Spray Pyrolysis 3-Zone Furnace for Nano Particles Synthesis - OTF-1200X-III-PGEP

Description

OTF-1200X-PGEP is a versatile ultrasonic spray furnace system designed for nano, core-shell structured particle synthesis. The system consists of three major modules: 1.7MHz ultrasonic enhanced bubbler, 1200ºC Max. 3 zone heating tube furnace, and Electrostatic Precipitator. The processing steps of a particle includes aerosol generation, thermal decomposition, and nanopowder collection. Such a system enables advanced synthetic method that provides control over particle size, morphology, nano/microstructure.

SPECIFICATIONS

System Structure  |

| |

| Tube Furnace - Thermal Decomposition  | Voltage & Power |

|

| Working Temperature |

| |

| Max. Heating / Cooling Rate | < 20oC / min | |

| Heating Zone & Constant Temperature Zone |

| |

| Heating Elements |

| |

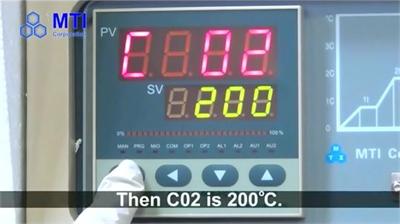

Temperature Controller |

| |

| Processing Tube |

| |

| Sealing Flanges & Fittings | ||

Aerosol Generation  | Ultrasonic atomizing bubbler |

|

Nanopowder Collection  | High Voltage Supply  |

|

Electrostatic Precipitator |

| |

| Net Weight | ~150Kg | |

| Dimensions |  ( click the picture to see details) ( click the picture to see details) | |

| Warranty | One-year limited manufacturer warranty with lifetime support (consumable parts such as furnace liner, processing tubes, and O-rings are not covered by the warranty, please order replacements at related products below). | |

| Laptop, software & WiFi Control (Optional) |

| |

| Compliance |

| |

Application Notes    |

| |

| Operation Video & Instructions |  | |