Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

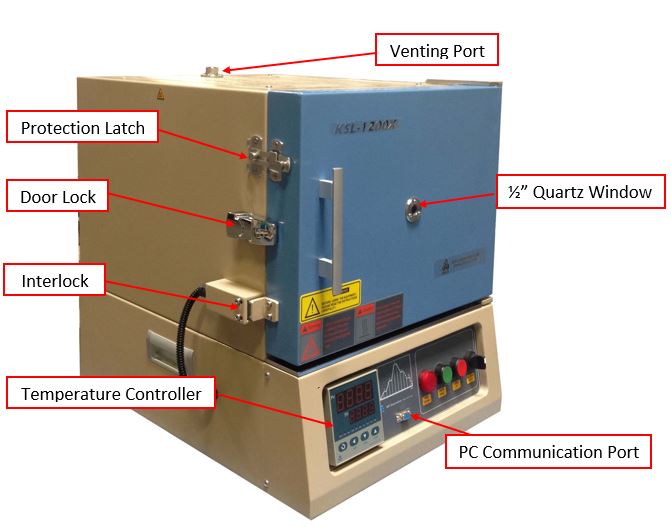

1200C Muffle Furnace (12x12x12", 27 L) w/ Programmable Controller- KSL1200X-M

Description

KSL-1200X-M-UL is a muffle furnace that offers 12" x 12" x 12" high purity fibrous alumina chamber, gas inlet and outlet ports and a 30 programmable segments temperature controller and UL / MET / CSA Certified electric components. It is the ideal muffle furnace for preparing samples with temperatures up to 1100 ° C in research and dental labs with maximum energy saving.

SPECIFICATIONS

Structure |

|

| Chamber Dimensions | |

| Power |

|

| Max Operating Temperature | 1200 ° C continuously |

| Temperature Stability | ±1 °C |

| Temperature Uniformity |

|

| Max. Heating Rate | 10 ° C/min |

Temperature Controller |

|

Temperature controller (optional) |

|

Laptop, software & WiFi Control (Optional)  |

|

| Gas Fitting & Exhaust |

|

| Product Dimensions | |

| Shipping Dimensions | 48" x 40" x 50" (D x W x H) |

| Shipping Weight | 320 lb |

| Warranty |

|

| Compliance |

|

| Application Notes |

|

| Operation Instructions |  |