| Part No. | OTF-1200X-4-HNG |

| Fused Quartz Tube Size | O.D: 101 x I.D: 92 x Length: 1000 mm |

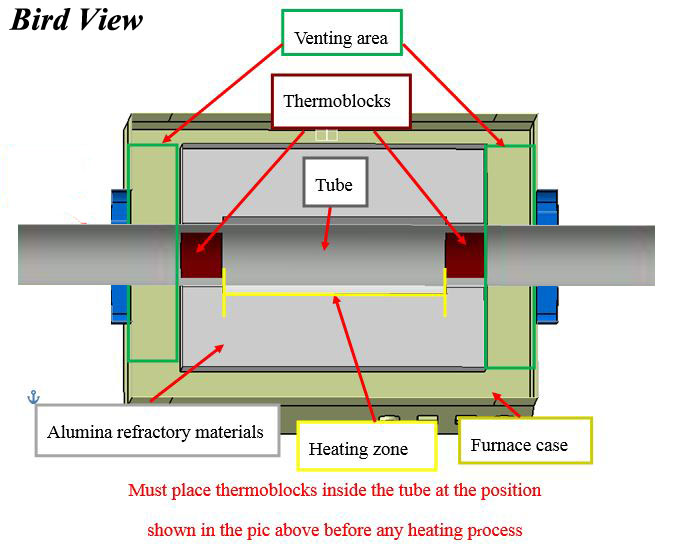

| Furnace Structure | Double-layer steel casing with air cooling to keep furnace surface temperature lower than 60°C. High purity fibrous alumina insulation for Max. energy saving. The special refractory coating on the inner and heating element to increase furnace life. Two Quartz tube blocks are included for blocking heat radiation from the inside the tube. ( blocks must be fully inserted into the furnace chamber before heating) |

| Input Voltage | 208 - 240VAC SINGLE PHASE, 50/60Hz |

| Power | 2.5KW |

| Heating Elements | Fe-Cr-Al Alloy doped by Mo |

| Heating Temperature | - Max. heating temperature: 1200°C < 1 hour ( inert gas must be filled inside the tube to resist deformation)

- Continuously heating temperature: 1100°C

- Heating rate: 20°C /min Max.

|

| Heating Zone | Total heating zone length: 440mm

Constant temperature zone: 150mm (+/-1°C) |

| Temperature Controller | - MET certified 30 programmable segments for precise control of heating rate, cooling rate, and dwell time.

- Built-in PID Auto-Tune function with overheating & broken thermocouple protection.

- Over-temperature protection and alarm allow for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

- RS485 Communications Port.

|

Advanced Temperature Control (Optional)

| - MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar. Click for detailed information about the MTS02-Y software kit.

- You may upgrade the temperature controller to the Eurotherm 3504 Temperature Controller which is fully compatible with LabVIEW. This package includes a Eurotherm 3504 programmer, a communication cable (RS485 - USB), and a software CD. Click the pic below to view the full spec of the Eurotherm 3504 temperature controller.

|

Hinged Type Vacuum Flange

& Fitting | |

| Vacuum Level | - 10^-2 torr by the mechanical vacuum pump.10^-5 Torr by a molecular pump.

- Leak rate < 5 mtorr / min.

|

| Optional | You may order a vacuum pump and accessories to build a complete vacuum furnace system as the pictures below, and please click Furnace Accessories to order these parts.

|

| Product Dimensions | Furnace: 590×380×520mm |

| Net Weight | 40Kg |

| Shipping Dimensions | 45 x 45 x 35 inch |

| Shipping Weight | 300lbs |

| Warranty | One year limited warranty

Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty

Please order the replacement at related products below |

| Laptop, software & WiFi Control(Optional) | - Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature profiles, manage heat-treatment recipes, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

|

| Compliance | - CE Certified

- NRTL or CSA certification is available at extra cost.

|

| Notes | Please click here to see our typical temperature profile calibration result at various temperatures. |

Application Notes

Click here to learn the installation of a gas regulator Click here to learn the installation of a gas regulator | - The tube furnaces are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 MPa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum pressures may only be safely used up to 1000°C

- The flow rate for gasses should be limited to<200 SCCM for reducing thermal shocks to the tube

|

| Operation Instructions |  |

Click here to learn the installation of a gas regulator

Click here to learn the installation of a gas regulator