Furnace Structure | |

Power | 2.5 KW |

Voltage | AC 208-240 Single Phase, 50/60 Hz |

Max. Temperature | 1250° C (<2hrs) |

Continuous Temperature | 1200°C (Continuous) |

Max. Heating Rate | <= 20°C /min |

Tube Size and Materials | |

Thermal Block Placement |  |

Heating Zone length | 440 mm ( single zone ) |

Constant temperature zone | 150 mm (+/-1°C) |

Temperature Controller  | - FA-YD518P-AG temperature controller is included.

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default DB9 PC communication port

|

Temperature controller (optional)

| |

Vacuum Seal & Upgrade | |

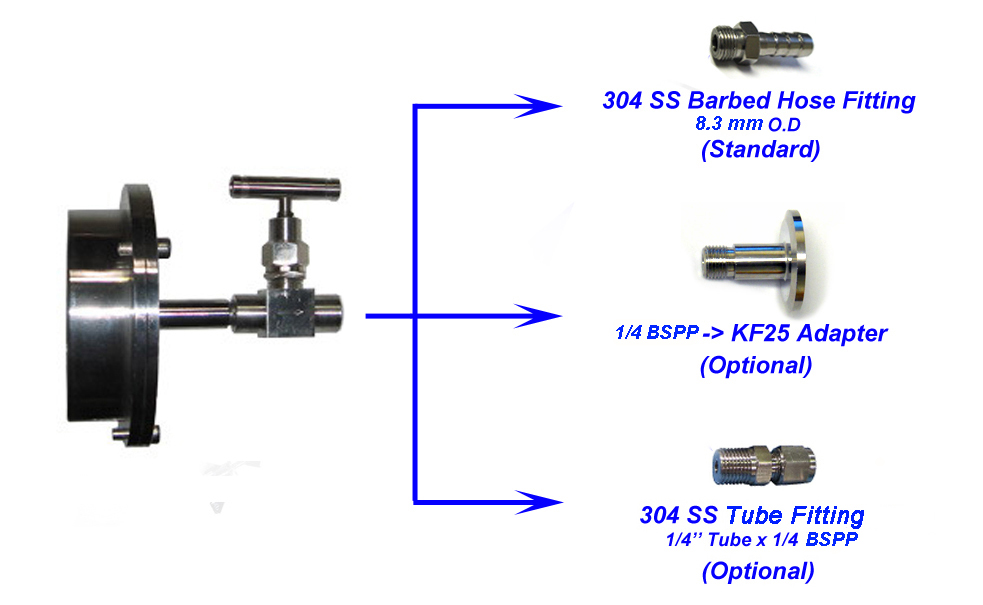

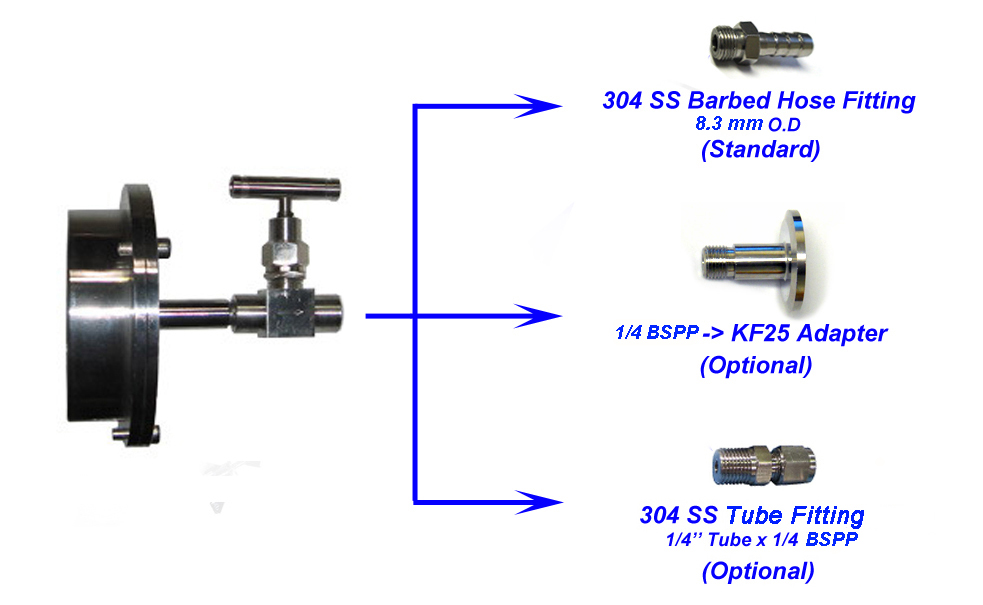

Fitting Ports

| - To achieve a high vacuum, you may replace the standard barbed hose fitting with the KF25 adapter; please click underline to order.

For supplying high purity gas, you may replace the standard barbed hose fitting with the VCR Face Seal Fitting; please click underline to order. |

Vacuum Level |   |

Heating Element | Fe-Cr-Al Alloy doped by Mo |

Dimension | 550 x 380 x 520 mm |

Net Weight | 40 Kg |

Shipping weight | 250 lbs |

Shipping package after crating | 48x40x40 i nch |

Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi

Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature profiles, manage heat-treatment recipes, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000).

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

| Compliance | - CE Certified

- NRTL or CSA certification is available upon request at extra cost.

|

Notice: | |

Application Notes

Click here to learn more about the installation of a gas regulator. | - The tube furnaces with mullite tube are designed for use under vacuum and low pressure < 0.02 MPa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the furnace chamber. The pressure gauge must be used to closely monitor the chamber condition at all times during the heating process; please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages.

- The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

- Vacuum pressures may only be safely used up to 1300°C

- NOTE The mullite tube shall be considered as a consumable part. We strongly recommend user keep spare tubes in order to ensure the continuity of operation. The tube is not covered by Warranty. Use the link to order more.

|

Operation Instructions |  |