Furnace Structure | -

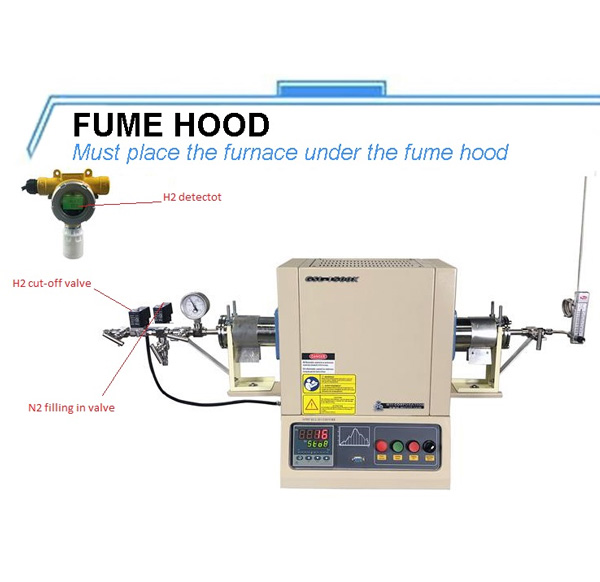

Double layer steel casing with air cooling to keep furnace surface temperature lower than 60°C. High purity fibrous alumina insulation for Max. energy saving. Hydrogen detector and solenoid valve are included for safe operation The hydrogen gas furnace must be placed under fume hood which is not included. Please click to view the spec of MTI EQ-FH-36 fume hood. |

| Power | |

| Working Temperature | - 1400 °C continuous operation

- 1500 °C (< 1 hour )

|

| Max. Heating Rate | |

| Processing Tube | Material: High purity Alumina Tube Tube Size: 50 O.D x 38 I.D. x 700 Length. (mm ) Two fibrous ceramic tube blocks are included for blocking heat radiation from inside tube.

(Ceramic blocks must be fully inserted into the furnace chamber before heating)

|

Heating Zone and Tempearture Uniformity | |

Temperature controller | PID automatic control via SCR (Silicon Controlled Rectifier) power control. Self-tuning and built-in protection from the overheated and broken thermocouple. Please click here to learn why SCR is more accurate than SSR (Solid State Relay) MET certified 30 programmable segments for precise control of heating rate, cooling rate, and dwell time. Over-temperature protection and alarm allow for operation without attendant(s). +/- 1 ºC temperature control during dwelling. RS485 Communications Port. Computer-access Temperature Control (Optional) MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar. Click for the detail information about the MTS02-Y software kit. You may upgrade the temperature controller to the Eurotherm 3004 Temperature Controller which is compatible with LabVIEW. This package includes a Eurotherm 3004 programmer, and a communication cable (RS485 - USB). (Optional - LabVIEW program and OPC service are not included) |

| Temperature Control | - +/ - 1°C during dwelling.

|

Flanges and Gas Inlet | - One pair of stainless steel vacuum flange is pre-connected for the two ends of the tube, which allows high vacuum up to 10E-5 torr and 5 PSI positive pressure.

- Two solenoid valvs are installed on the left of the flange for Hydrogen gas and N2 gas inlet. It connects with hydrogen detector. Once hydrogen gas leak is detected (20% lower explosive limit (LEL)),H2 gas inlet valve will be closed and N2 gas valve will be opened, and heating elements will be shut down immediately

- One pressure gauge and a needle valve is installed to control the Hydrogen gas pressure, which must be less than 0.03 MPa.

|  | | Left flange side | Right flange side | |

Hydrogen Detector System

(included) (included) | One Honeywell UL Approved Sensepoint Gas Detector is Integrated into the system. Working Temperature Range: 40ºF to +149ºF (-40ºC to +65ºC) Alarm Point: H2 Limited Explosive Line 20% (20% LEL). Once detecting H2 gas beyond the point, it will shut off the inlet valve to the H2 and heating elements automatically. |

Gas-outlet Flowmeter | One 0 -1000 ml/min floating meter is installed on gas-outlet end for adjusting gas flow rate. 1/4" Dia stainless steel tube is installed for burning hydrogen gas during gas flowing. One long lighter is included in the standard package for igniting hydrogen gas manually. Solenoid value automatically shuts down the gas inlet and heating elements in case of system failure. |

| Heating Element | |

| Furnace Dimension | 400 x 300 x 530 mm (15.7" x 12" x 21") |

| Net Weight | 140 lbs |

| Shipping Weight | 200 lbs |

| Shipping Dimension | 45" x 25" x 37" |

| Warranty | One year limited warranty for electrical and mechanical parts

Attention: A free course of safety operation training at MTI field is required to purchase this furnace. A customer's side training is also available upon request at extra cost. If the users believe that they have sufficient experience and knowledge to handle the furnace in the dangerous or emergent situation, a liability release agreement must be signed at the purchase. MTI Corp. is not responsible for any damages caused by misuse without the safety operation training. Any damages caused by the corrosive and acidic gases are not under the coverage of the MTI One Year Limited Warranty. |

| Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables user to edit temperature profile, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters operating range.

- Above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

| Compliance |

|

Warning

Click here to learn more about the installation of a gas regulator.

| - The tube furnaces with alumina tube are designed for use under vacuum and low pressure < 0.02 MPa / 0.2 Bar/ 3 PSI

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Never heat the furnace while the gas release valve is closed and a positive pressure shall keep within the furnace chamber.

- The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

- The hydrogen gas furnace must be placed under fume hood Please click here to view the spec of MTI EQ-FH-36 fume hood.

- Vacuum limit definition for all alumina tube furnaces: * Vacuum pressures may only be safely used up to 1500°C

|

| Operation Instructions |   |

(included)

(included)