Furnace Structure

| - Double-layer steel casing.

- High purity 1800oC grade fibrous alumina insulation

- Alumina processing tube, vacuum & gas sealing flange with valves, vacuum gauge, thermal blocks are included

- Quenching liquid tank is built on the bottom for immediate use

- Quench sample up to 50mm dia, x 65 mm L under inert gases and vacuum

|

Power Input | - Single Phase, 220V AC +/- 10%, 50/60 Hz

- Max. 4000W (4 KW )

- 20A air breaker required

- 10 feet length 10-3 AWG heavy duty UL approved power cable is included. Extra length cable can be ordered by click picture below-left

- The plug is not included. Browse our catalog for compatible plugs or obtain one from a local hardware store.

|

Working Temperature: | - Max. working temperature: 1700 oC (3092 oF) for < 1 hours

- Continous working temp.: 800-1600 oC (3002 oF)

|

Heating / Cooling Rate | - 5 oC / min above 1200 oC

- 10 oC/min below 1200oC

|

Heating Elements &

Heating Zone | - 4 pcs of U-shaped 1800 grade MoSi2

- Heating Zone Length: 130mm

- Constant Temperature Zone: 60 mm within +/- 5 oC

|

Temperature Controller

Temperature controller interface

The optional PC control module

Optional Eurotherm 3000 | - Standard temperature controller:

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default DB9 PC communication port (PC control module and software are sold separately. See optional.

- Optional:

- MTS-02 PC control module (also including cable and software) is an add-on option for PC control.

- It is recommended to purchase the module together with the furnace. We install and test it before shipping.

- It is recommended to purchase the laptop (with software pre-installed) from us to avoid software conflict.

- Please note the module is not sold solely in the future.

- Eurotherm 300 Temperature Controller with +/- 0.1ºC accuracy is optional for an additional $950 including installation and testing. This package also includes the communication cable (RS485 - USB) and software CD. Click here to view the full spec.

|

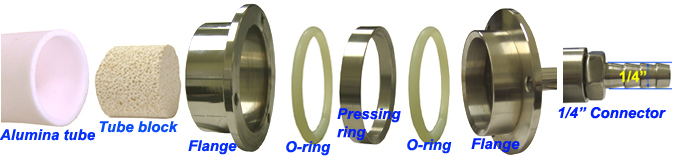

Processing Tube  | - 99.8%High purity Al2O3 Ceramic, ID: 54mm; OD: 60 mm x Length 800 mm

- Two fibrous ceramic tube blocks are included for blocking heat radiation from the inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating)

- You may consider using a tungsten wire to hang up a crucible or sample to quench sample ( click Pic right to learn )

|

Vacuum Sealing and Valve | - Vacuum pressure can reach 50 mTorr by a quality mechanical vacuum pump and 10^-5 torr by turbo molecular pump. Please click the picture below to see the flange assembling details.

- Optional: You may consider using the parts below to increase the vacuum efficiency

|

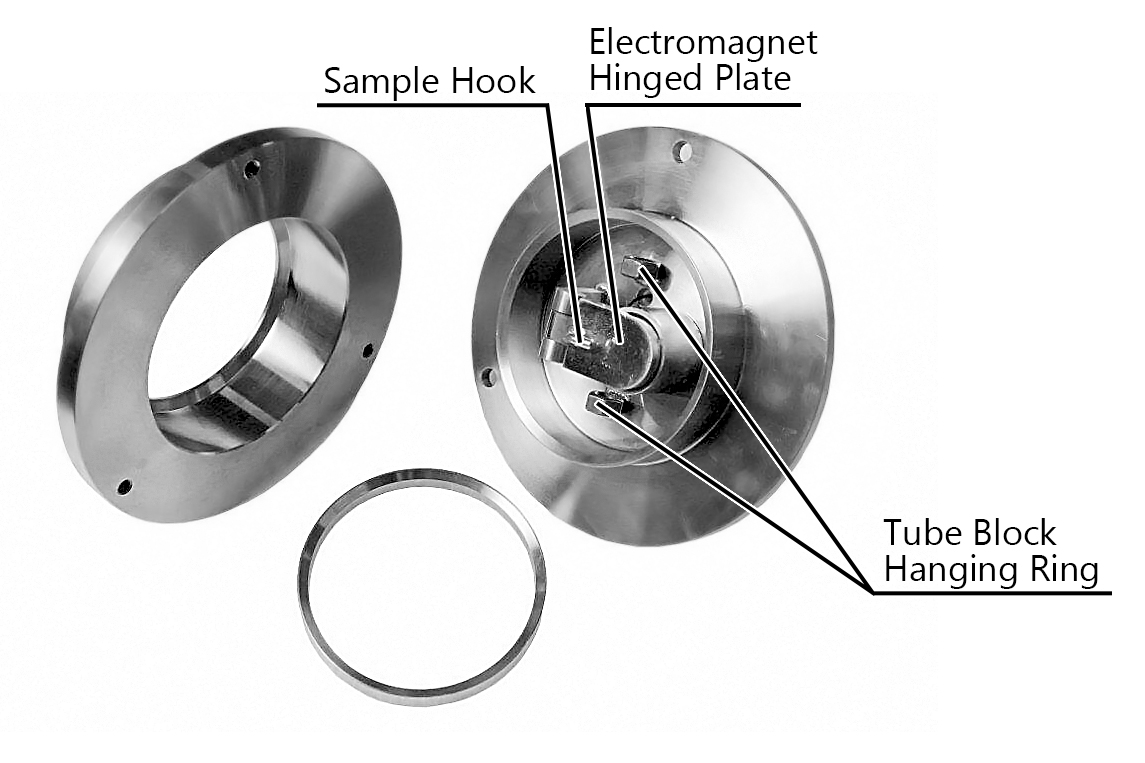

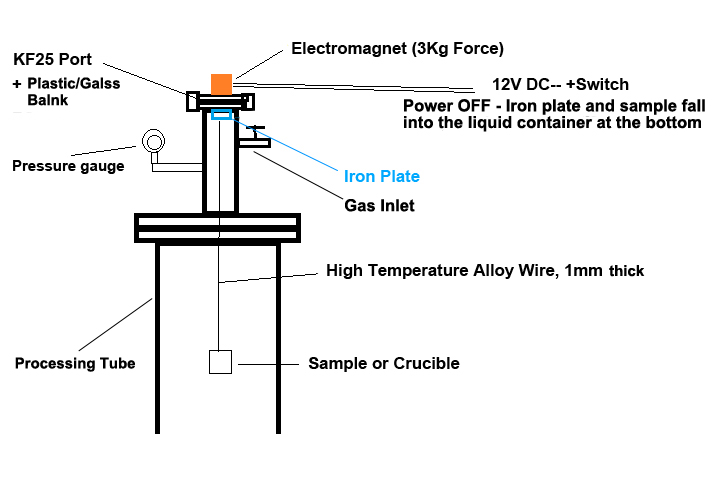

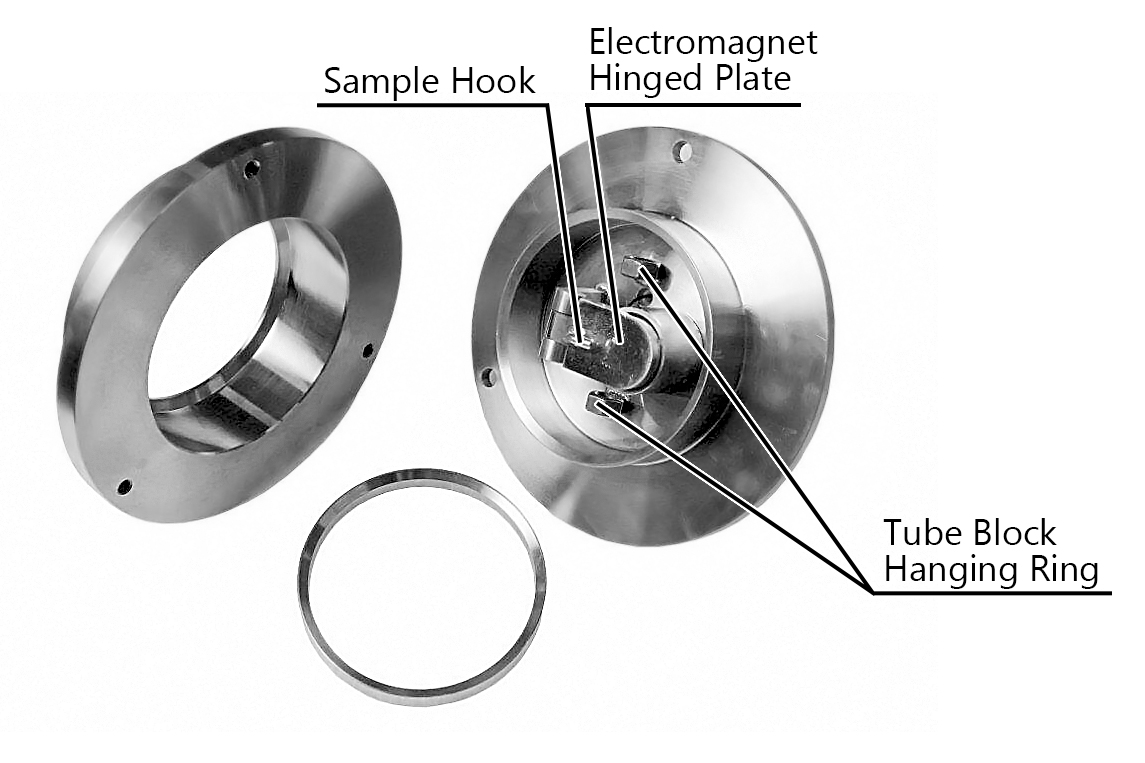

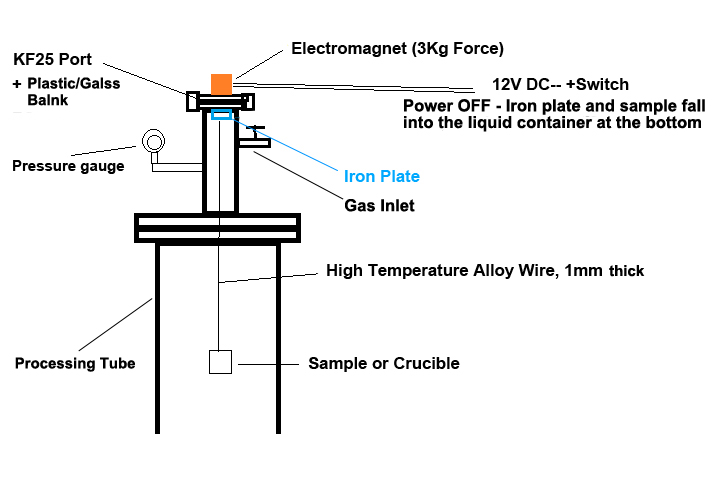

Electromagnet Sample Release Flange & Quenching

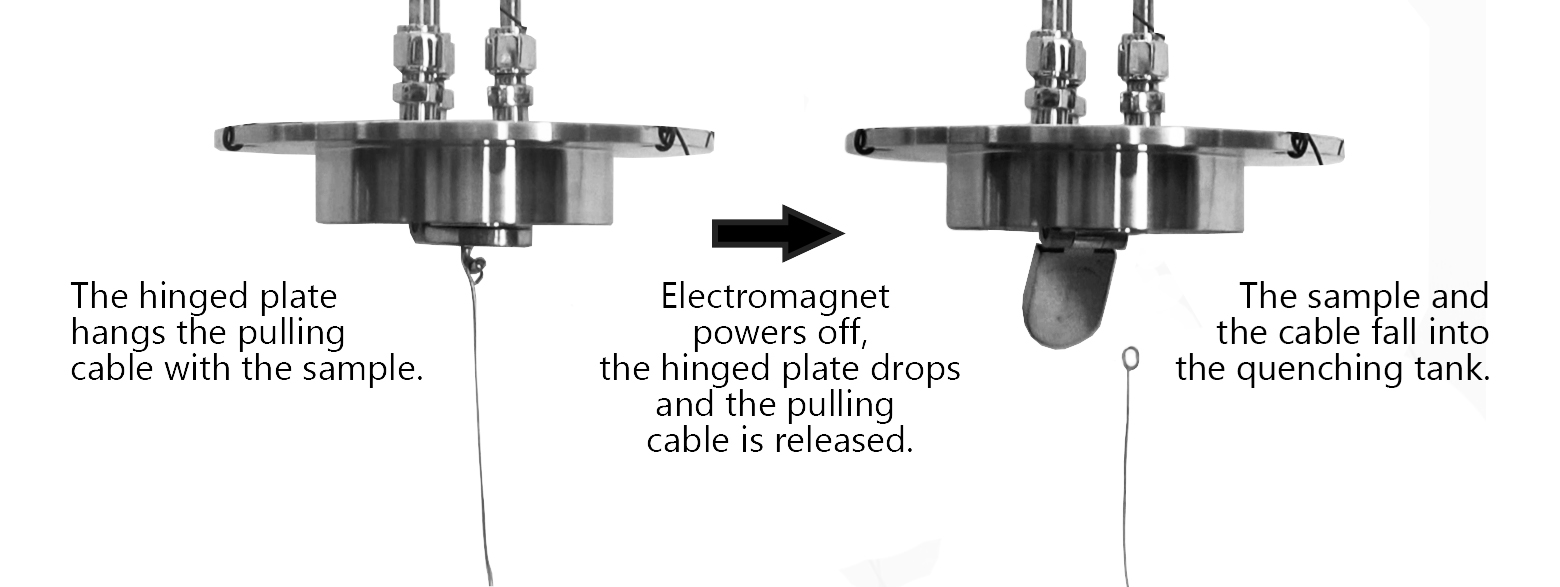

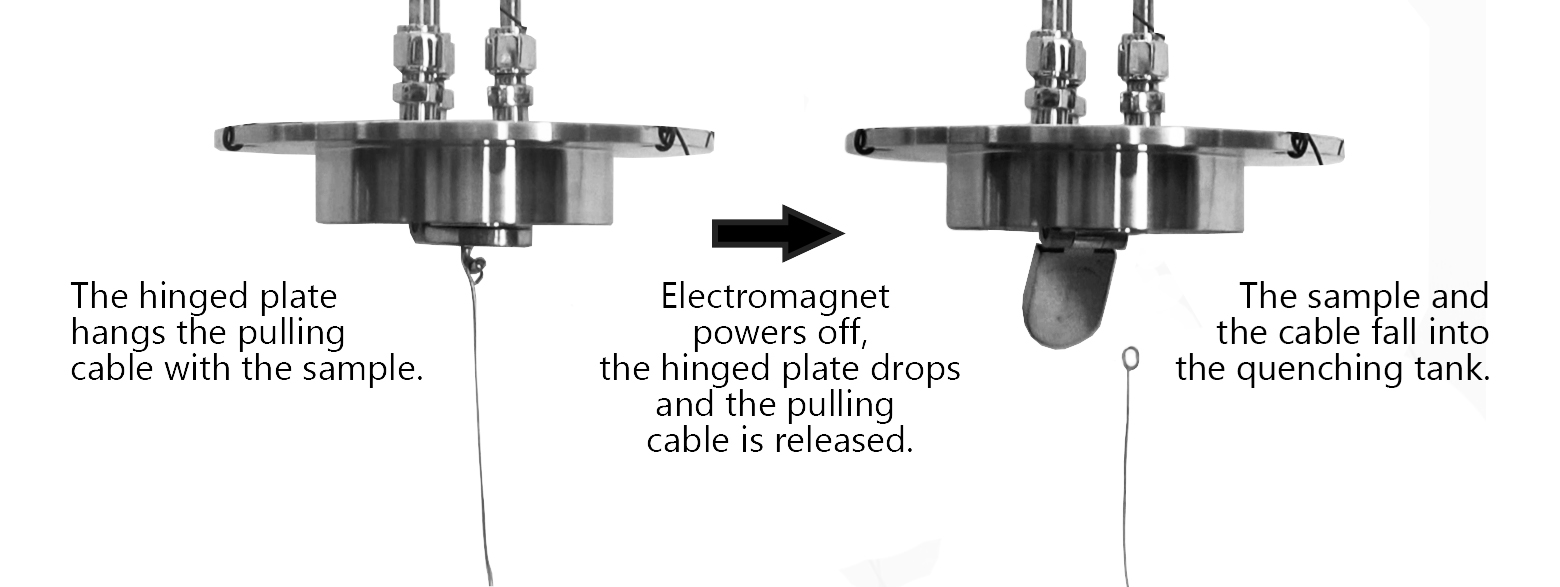

| - Full automatic electromagnet sample release flange

- Hinged plate hooks the cable, which pulls the sample.

- Hinged plate drops when the electromagnet powers off. The sample and the cable fall into the quenching tank.

- Rings are available for hanging the tube block with cables.

- Bottom flange is connected with a 4" gate valve ( manual operated ) via CF-100 adaptor

- The gate valve is connected with a quenching media container in size 400 x400 x 200 H ( mm )

- Caution: You must use ice water or cooled oil as a quenching media if quenching under vacuum.

|  |  |  |  |  | | 1. Flange Structure | 2. Flange Operation | 3. Gate Valve | 4. Quenching Tank | 5. Quenching | 6. Pulling Cable |

|

Quenching operation | - One stainless steel tank is located on the bottom of the furnace to contain quenching liquid.

- One large gate valve is built on the bottom tube

- One electromagnet is installed on the top flange and hold sample hanging wire up to 500 g

- Touch the release button of the electromagnet on the temperature control unit, the sample will drop to the liquid tank.

- Before release, the sample must fill argon gas to 5 psi and open gate valve

|

Gas Purification and Circulation

(Optional)

| - EQ-RMP-1 is an automatic recirculating moisture and oxygen purification system, which can provide an environment with moisture and oxygen concentration lower than 1 ppm for MTI's furnaces and gloveboxes.

- Two-columns of Molecular sieves are Built-in in the system. One is for removing oxygen and another is for removing moisture up to < 1 PPM

- The automatic pressure control system is built in to keep the pressure at a constant level

- 6" color PLC touch panel is included which can set and display the humidity and pressure level

- Oxygen sensor and moisture sensors are included.

|

Hermetic Quenching Tank

(Optional) | - Hermetic quenching tank is optional for air-sensitive materials, which enables the entire quenching process under atmosphere control

- Please contact MTI for further inquires.

|

Dimension |  1080×650×1600 mm 1080×650×1600 mm |

Net Weight | |

Shipping Dimensions | |

Shipping Weight | |

Warranty | One-year limited warranty (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Certificates | - CE Certified

- NTL(UL61010) or CSA certification is available at extra cost.(please click marks below to learn details )

|

Warning | MoSi2 heating element is used in high temperature under an oxidizing atmosphere. During the oxidizing process, the SiO2 protective film is formed again the heating element from melting during sustained use. The MoSi2 heating element must not be used in the temperature between 400 oC and 700 oC for a long time, otherwise, the element will be cremated under the strong oxidizing atmosphere at low temperatures. |

Application Notes

Click here to learn more about the installation of a gas regulator. | |

Operation Instructions

& Video |   |