Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

1700C Tube Furnace with High Vacuum System (1.0E-4 torr) - GSL-1700X-HV-UL-LD

Description

GSL-1700X-HV furnace consists of a high-temperature alumina tube furnace and a high vacuum system. It can be heated up to1700°C by a different type of MoSi2 heating elements and achieve vacuum pressure up to 10^-4 torr with a diaphragm pump. It is widely used for material or chemical lab to sinter all types of new material samples under vacuum or other gas conditions. The temperature of the tube furnace is controlled by 30 segments programmable high precision SCR power controller with accuracy +/-1°C.

Specifications

| Furnace | Furnace structure | Double-layer steel casing with air cooling. Two cooling fan inside to keep case temperature < 55°C | |||||||||

| Tube Materials | 99.8% High purity Al2O3 Ceramic | ||||||||||

| Tube Size | 82mm O.D Alumina tube ---------- ID: 73mm; OD: 82 mm in diameter x 1000 mm length | ||||||||||

| Refractory lining | 1750 grade fiber alumina cast | ||||||||||

| Heating element | MoSi2 | ||||||||||

| Working Temperature | 1700°C (2912°F) Max. <1hr 1600°C continuously | ||||||||||

| Normal Working Temperature | 800 -1700°C (2732°F) | ||||||||||

| Temperature Controller |

| ||||||||||

| Max. Heating / Cooling Rate | 5°C / min above 1200°C and 10°C/min below 1200°C | ||||||||||

| Heating Zone | 457 mm (18") | ||||||||||

| Constant Temperature Zone | 150 mm (6") (+/- 1°C at 1600°C ) | ||||||||||

| Temperature Accuracy | +/- 1°C | ||||||||||

| Power Input | Single Phase, 220V AC, 50/60 Hz | ||||||||||

| Power Output | Max. 5KW | ||||||||||

| High Vacuum Station | Structure | Mobile cart size: 600 (L) x 600 (W) x 700(H), mm Max. Loading: 600 Lbs on top Molecular pump control Panel: LCD digital Inside: Pfeiffer vacuum pump made in Germany Vacuum sensor is included | |||||||||

| Vacuum sensor | Two vacuum gauges are installed in this system. 1. Mechanical vacuum gauge 2. High vacuum gauge (measuring range 10^-8 mbar ~ 10^3 mbar) is installed in the whole high vacuum system for monitoring the high vacuum status when operating the furnace with HV station support. | ||||||||||

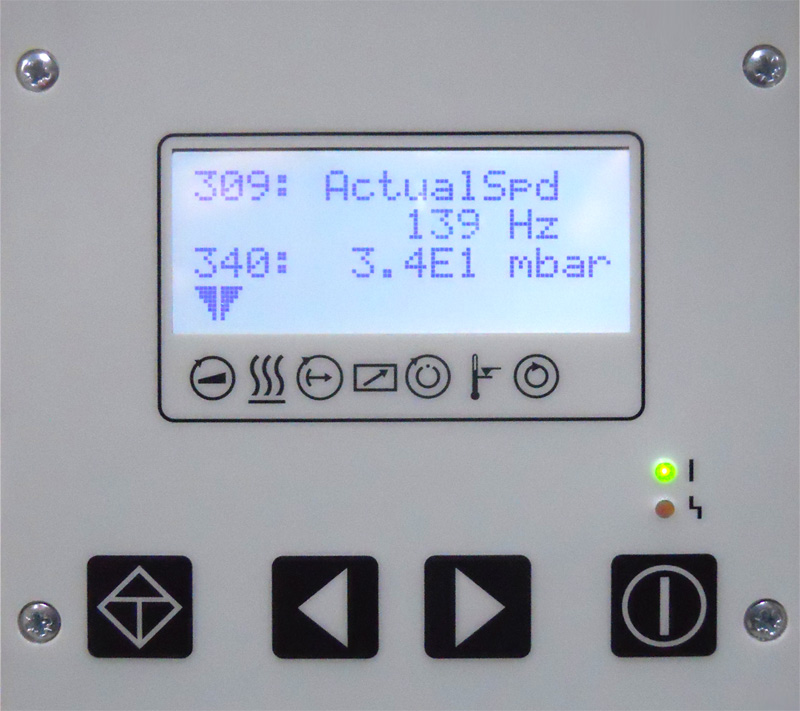

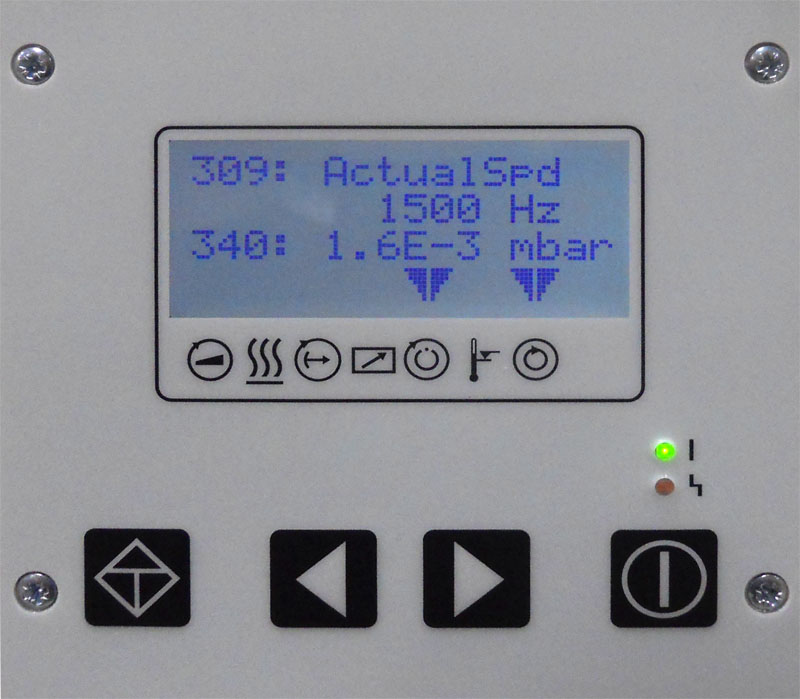

| Control Panel | One button operation - the diaphragm pump and the turbomolecular pump will start after pressing the "start" button. System controlled spinning speed - the controller will control the speed of the turbine spinning up and down according to the vacuum level and leaking rate of the reaction chamber. Self-protection - the system will protect the pump from damage by overheating and over-current if the leaking rate of the reaction chamber is too high to achieve a high vacuum. LCD screen - double lines parameters checking interface make the working easier to be handled.

| ||||||||||

| Volume Flow Rate | Nitrogen N2 33 L/s Helium He 39 L/s (2340L/minute) Hydrogen H2 32 L/s | ||||||||||

| Working Range | From 1000 mbar to <1E-6 mbar (under Cold Condition only; Noted: Please don't use a high vacuum if the temperature is over 1500 °C) | ||||||||||

| Ultimate Pressure | <1E-8 mbar (without any leaking) | ||||||||||

| Power Input | 110V AC or 220V AC switchable, 50/60Hz | ||||||||||

| Power consumption | Duration/Max power: 100/110Watt | ||||||||||

| Shipping Info | Product Dimension | Tube Furnace: 550 L x 450 W x 670 H mm (21.7" L x 17.7" W x 26.4" H) Mobile bench with vacuum system: 600 x 600 x 700mm | |||||||||

| Net Weight | Furnace: 150 kg (330 lbs) Mobile bench with vacuum system: 50 lbs | ||||||||||

| Shipping dimension | Two Cases of 47" x 45" x 45"(1200L x 1150W x 1150Hmm) | ||||||||||

| Shipping weight | 450 Lb (175kg) | ||||||||||

| Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) | ||||||||||

| Compliance |

| ||||||||||

Note Click here to learn more about the installation of a gas regulator. Click here to learn more about the installation of a gas regulator. |

| ||||||||||