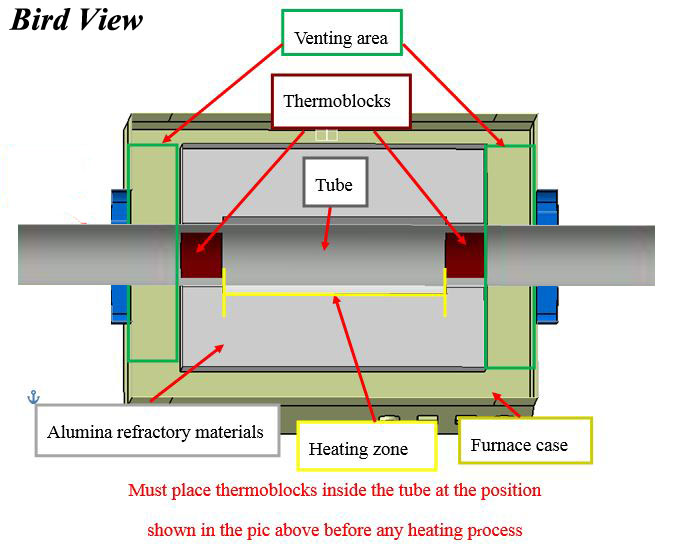

Furnace structure  | Double-layer steel case with two cooling fans which ensure low surface temperature; Energy-saving high purity fibrous alumina insulation; Two fibrous ceramic tube blocks are included for blocking heat radiation from inside of the tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating). Quartz block (Optional) is ideal for more cleanness and a higher achievable vacuum. The furnace can be separated from the temperature controller and place it on remote location    Click here to choose a crucible Click here to choose a crucible

|

| Rated voltage | AC 208-240V Single Phase, 50/60 Hz (30A breaker required; Powder cord is included without plug) |

| Power consumption | 5KW Max. |

| Heating elements | Fe-Cr-Al Alloy doped by Mo |

Heating zone length

| - Three zones: 610mm (24") in total

- Z1 - Z2 - Z3:152.4mm (6") + 304.8mm (12") + 152.4mm (6")

- +/-1ºC Constant Temperature Zone: 260 mm length

- +/-2ºC Constant Temperature Zone: 480 mm length (click the pic below for detail)

|

Fused Quartz Tube

| Model: OTF-1200X-III-S-UL-60

60 O.D x 55 I.D x 1200 L (mm) | Model: OTF-1200X-III-S-UL-80

80 O.D x 72 I.D x 1200 L (mm) | Model: OTF-1200X-III-S-UL-100

101 O.D x 92 I.D x 1200 L (mm) | Model: OTF-1200X-III-S-UL-5

130 O.D x 122 I.D x 1200 L |

| Warning: The tube furnaces with quartz tube are designed for use under vacuum and low pressure < 0.12 Mpa (absolute pressure) |

| Heating temperature | Max. Heating Temperature: 1200°C (<1 hour) Continuous Heating Temperature: 1100°C Max. Heating Rate: 20°C/min |

Temperature Controllers  | - Three MTE certified Temperature controller with 30 programmable segments

- Built-in PID Auto-Tune function with overheating & broken thermocouple protection.

- Over-temperature protection and alarm allow for operation without an attendant.

- +/- 1 ºC temperature accuracy.

- Three K-type thermocouples (one for each zone).

- RS485 Communications Port.

|

European Temperature Controllers (optional upgrade)

| - 1 heating channel

- 1 program of 8 or 24 segment

- Alarm Relay: Form 'A' and Form ‘C’ built-in

- Digital Communications: RS485

- Temperature Accuracy: ± 0.1ºC

- Recipes: Using a PC tool recipes can be created that can be used to change the operating parameters of the 3000 simply by selecting a new recipe via the HMI. This is very useful where multiple products are processed using the same controller but require different parameters to be set.

|

| Vacuum Flange and Gauge | - One pair of SS 304 vacuum flange with double high-temperature silicone O-ring is Included

- Default flange with 1/4'' Bard fittings, 1/4'' tube feedthrough port (for 1/4" O.D thermocouple insert) and a KF25 vacuum port(click bottom left picture to see details )

- One Vacuum/ pressure gauge is installed one side flange

- The vacuum level can reach 10E-2 torr by the quality mechanical vacuum pump and 10E-5 torr by molecular pump

- Optional:

- You may choose a hinged type flange ( see pic below middle ) to make sample loading at easy.

- You may order the digital molecular pump for a faster and better vacuum

- You may order flange support to avoid tube rotating ( click Pic below right )

|

| Dimensions | 800mm(L) x435mm(W) x 670 mm(H) |

| Net Weight | ~70 kg |

| Shipping Dimensions | 55"(L) x 45"(W) x 45"(H) |

| Shipping Weight | 340lbs |

| Warranty | One-year limited warranty with lifetime support. (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacements at related products below.) |

Laptop, software & WiFi Control(Optional)

| - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature profiles, manage heat-treatment recipes, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

|

Compliance

| - CE certified

- NRTL or CSA certification is available upon request at the extra cost

|

| Application Notes | |

| Operation Demo Video |   |

.jpg)