| Model | GSL-1100X-6-III | GSL-1100X-8.5-III | GSL-1100X-11-III |

| Fused quartz tube size | - High purity quartz tube

- Warning: quartz tube is fragile, please handle with care. Warranty does not cover the broken tube by use

|

Size:

152 O.D x 143 I.D x 1300mm L

(6" O.D x 5.6" I.D x 51" L) | Size:

216 O.D x 206 I.D x 1300mm L

(8.5" O.D x 8.1" I.D x 51" L) | Size:

279 O.D x 269 I.D x 1300mm L

(11" O.D x 10.6" I.D x 51" L) |

| NOTE: The customers must define one tube size before purchase. It is very difficult to change the tube size after because the chamber liners need to be replaced in order to fit the different tube sizes. |

| Quartz boats (optional) | max. 4" wafer boat compatible

| Max. 6" wafer boat compatible

| Max. 8" wafer boat compatible

|

| Furnace structure | - Double-layer steel casing with air cooling. The surface temperature of the case is < 70°C.

- Refractory fibrous alumina insulation liner for maximum energy saving.

- Heating element: NiCrAl Resistance Wire

- Two fibrous ceramic tube blocks are included for blocking heat radiation from the inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating)

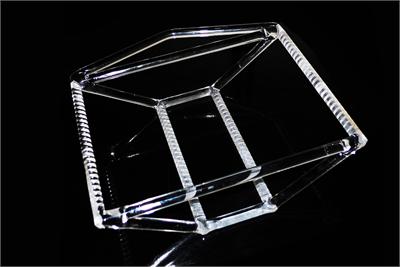

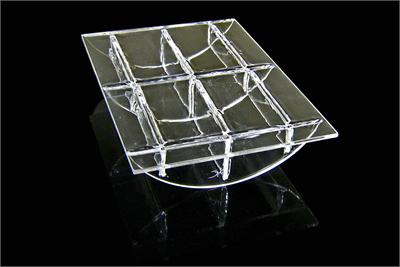

- This furnace can be used as an annealing or diffusion furnace for 8" wafer uses a quartz boat at the related product below

Holding 8" wafer Holding 8" wafer |

| Heating zone | - Total heating zone length 900 mm (36")

- Three zones: 300 mm + 300 mm + 300mm (12" per zone)

- Constant temperature zone:

- 750 mm (if three zones are in the same temperature within +/- 3°C) longitude direction

- 600 mm (if three zones are in the same temperature within +/- 1°C) longitude direction

- +/- 3 oC along the cross-section

|

Working temperature

| - Max heating temperature: 1100°C ( < 1 hour )

- Normal working temperature: 200~1000°C

- Max heating & cooling rate: 10°C/min

- Temperature uniformity: please click the pic left to enlarge

- Optional: If use GE special quartz tube, working temperature can reach 1150oC under vacuum at the extra cost

|

Temperature control

| |

| Vacuum sealing & Flange

| A pair of SS vacuum sealing flange (Hinged Type) and 4 pieces of silicon O-ring are included. Left Side Flange: Vacuum gauge, stainless steel needle valves, and 1/4" barbed hose fitting. Right Side Flange: KF40 vacuum port with KF-40 Vacuum Right-Angle Valve for easy connection to KF40 bellows and pump. ( If using a pump with a KF25 port, you will need an adapter KF40-KF25. - One 1/4" OD thermal couple insert port is built in the flange for easy temperature calibration.

- Vacuum Level: 10-2 torr by heavy-duty mechanical pump and 10-4 torr by regular turbo-pump. 5x10-7 torr can be reached by 700 L/s high-speed turbopumps and a modified flange adaptor

|

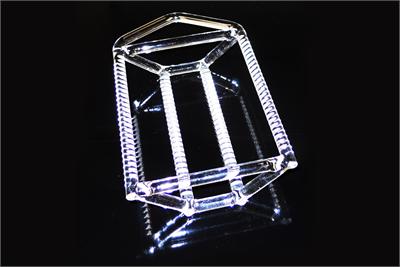

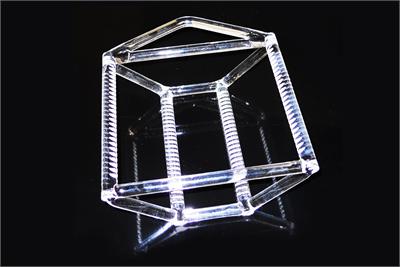

Options Click to enlarge | - The tube furnace should be calibrated regularly to maintain temperature accuracy and uniformity. We are providing a simple calibration kit for you to complete this job at an extra cost The complete calibration kit includes (click the underline to see details):

- You may consider ordering turbopump for hi-vacuum up to 10-5 torr ( click pic below right to order )

|

| Rated Voltage | - Single Phase, 220V AC, 50/60 Hz

- AWG 8# Power cord is included (without plug)

|

| Power consumption | Max. 8KW (50A breaker required) |

| Product Dimension | 1879 L x 680W x 920 H mm (74" L x 24.5" W x 37" H) |

| Net weight | 200kg |

Shipping dimension

| 80" x 40" x 70" |

Shipping weight

| 800 lbs |

| Warranty | - One year limited warranty for electrical parts. ( Consumable parts such as processing tubes, o-rings, and quartz tube are not covered by the warranty)

- You may order a replacement quartz tube at the link below

|

| Laptop, software & WiFi Control(Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipes, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000).

|

| Compliance | - CE Certified

- NRTL or CSA Certification is available upon request, additional charges will apply

|

| NOTE | |

| Operation Instructions |

|

Warning

| - Tube furnaces with quartz tubes are designed for use under vacuum and low pressure < 0.2 bar / 3 psi

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum pressures may only be safely used up to 1000°C

- The flow rate for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

|

Holding 8" wafer

Holding 8" wafer