Description

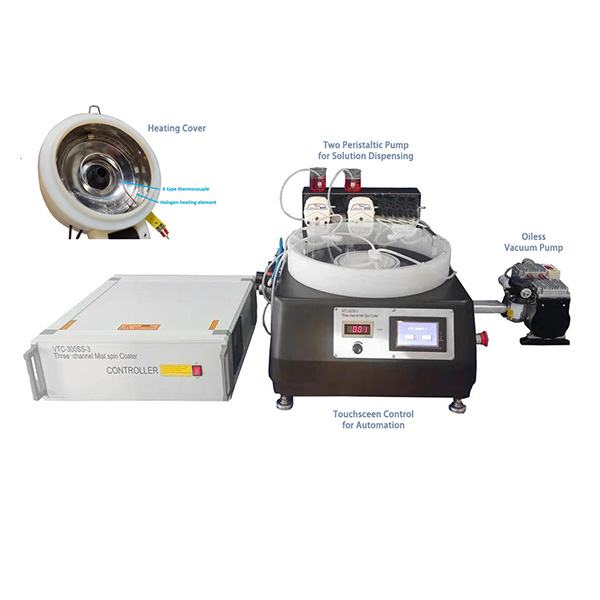

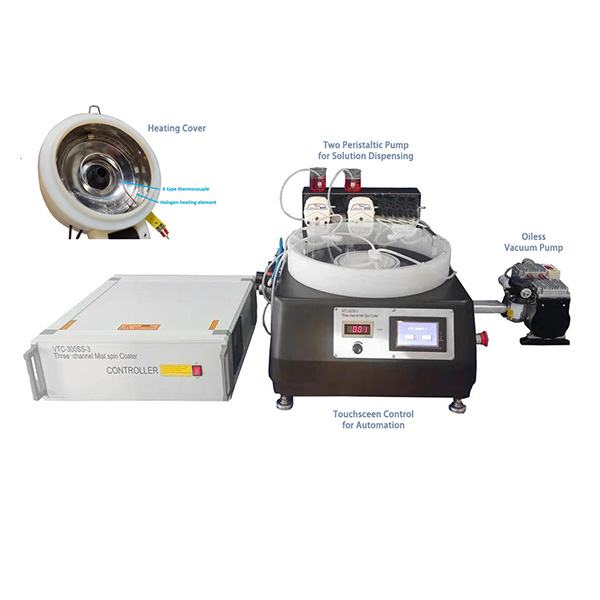

VTC-100ML-HC is an automated multi-layer spin-coating unit with a rotational speed of 10000 rpm and a heating cover up to 200℃. Integrated with two peristaltic pumps, it automates the cycles of spin-coating and drying process for two different solutions. With its modularized design, three or more channels of coating solutions can be simply added for layer-by-layer assembling.

Please note that the diagrams and product images are for illustrative purposes only. The final product may differ.

SPECIFICATIONS:

| Features | - Automated Spin-coating-drying-cooling process. One-click for multilayer programmable coating.

- Spinning Speed: 500 ~ 10000 RPM

- Substrate size: 10 mm to 4"

- Polypropylene Chamber with IR heating cover, up to 120ºC.

- Optional PTFE Chamber, up to 200ºC

- Two mini SS nozzles with IR heating cover with precision temperature controller up to 120ºC

- Two precision peristaltic pumps for solution dispensing with an increment of 9-10 μl

- Touchscreen panel for easy control and monitoring.

|

| Power | - 110 VAC, single phase

- 2 kW

|

Chamber and Cover

| - Chamber size: 150 mm diameter

- 2 sets of Aluminium vacuum chucks for substrates from Φ 25 - 100 mm.

- choice of material, PP or PTFE, for chamber and cover.

- IR heating cover with a single point PID temperature controller, up to 120ºC or 200ºC upon chamber material.

-

|

Vacuum Pump

| - One 120L/min Oilless Vacuum Pump is included

- For use in the Ar glove box, a feedthrough is required at an extra cost for a vacuum pump connection.

|

| Peristaltic Pump | - Two peristaltic pumps with flow sensor

- High precision liquid dispenser with a minimum increment of 9-10 μl per injection.

|

Nozzle

| - Two mini SS nozzles to dispense the liquid

- Elevation lever to prevent dispensing liquid from drying

|

| Cooling | - A 1/4" gas port for cooling gas connection

- An integrated solenoid valve for cooling gas on/off.

|

Control Panel

| - Touch screen control panel to program the process.

- Speed: 500 - 10000 RPM, 6 segments, 30 seconds max for each segment.

- Acceleration speed: 200-2000 RPM.

- Solution Injection Amount

- Dwelling time

- Heating rate, heating temperature, and dwell time

- Cooling air on/off, cooling temperature

- Number of coating for each solution up to 500 times of each solution

|

| Automation | - The automated multilayer coating process is as follows,

- Wafer and solution preparation and loading

- Vacuum on

- Liquid dispensing solution A

- Spin-coating solution A

- Dwell

- Drying by the IR heating

- Cooling by the air

- Liquid dispensing solution B

- Spin-coating solution B

- Dwell

- Cooling by the air

- Repeat the cycle

|

| Operation Video |  (video for heatable cover) (video for heatable cover) |

Warranty &

Compliance | - One year limited with lifetime support

- CE Certified

- NRTL or CSA certification is available at an extra cost.

|

| Warnings | - Do not overflush the water bowl/base with any kind of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use a fabric cloth to wipe out the residues that remain in the bow/base.

- Please turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation.

- For more details about the cleaning procedure, please review the cleaning instruction for the spin coaters.

|

| Shipping Dimensions | 40"(L) x 30"(W) x 30"(H) |

| Shipping Weight | 46 kg (100 lbs) |