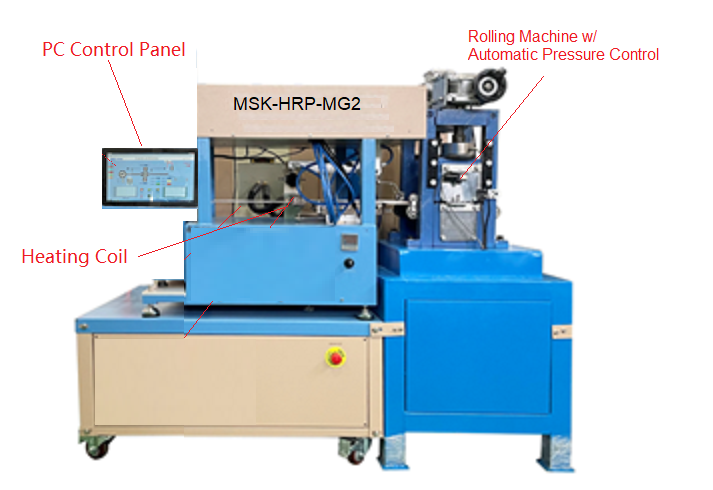

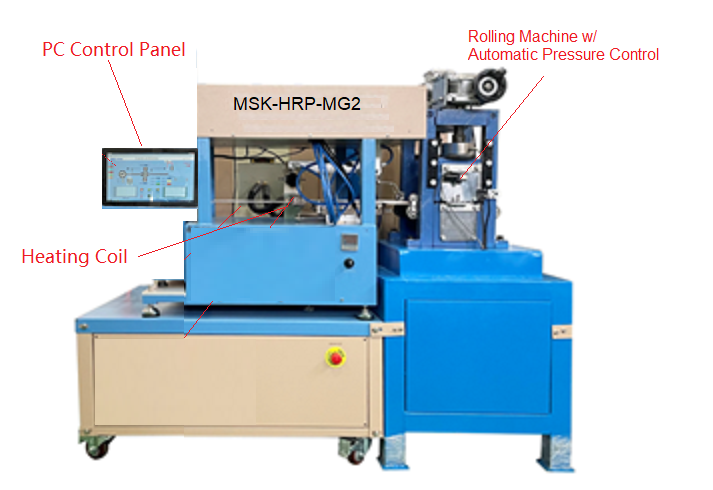

Description

MSK-HRP-MG3 is a lab-scale automatic hot rolling machine for research of metallic alloy strengthening via deformation. It can roll the single metallic sample up to 50 mm width at max. 900 oC at controlled pressure via PC program at the different rolling temperatures, rolling amounts, and repeating times by touch one button.

SPECIFICATIONS

Rolling Press

| - Roller Dimension: Φ121mm x W 150mm

- Roller material: 4Cr5MoSiV1(H13)with hardness HRC 55 ( RT ) and HRC 40 ( 450ºC)

- Rolling Speed: 0 - 20 RPM adjustable and independently controlled for two rollers

- Rolling motors: Two motors with 1:72 gear and Max. torque 4000Nm.

- Pressure sensors: Two sensors to display pressing force up to 7 metric tons with digital display

- Rolling thickness: Max. 30 mm max and Min. 0.1 mm

- Rolling amount: 0.04 - 0.5 mm programmable for each rolling with digital display

- Max. rolled sample size: ≦ L200 x W 40mm,Thickness ≧1mm

- Heating plate: The heating plate in the entrance with 450ºC Max.

- Material to be rolled: < 28 HRC

- Input Power: 8KW, three-phase, 208- 240VAC , 50/60 Hz

|

Induction Heating System

| - The sample will be heated by an induction coil when it moves to the heat zone

- IR temperature sensor will oscillate with induction coil to control sample temperature to the setting value.

- Induction coil oscillating speed: 1-10mm/S programmable

- Max. heating temperature: 950oC max. programmable

- Induction power 208- 240VAC, three-phase, 20KW

|

Sample Travel

| - A single sample will be placed on the sample stage and automatically travel to the induction heating coil, rollers, and cooling chamber as PC programma

- Max. sample size: 30 mm thickness and 30 mm width and 200 mm length

|

| Cooling System | - After recirculation of hot rolling, the sample will be placed on a cooling plate via a pneumatic clamp

- The sample will be cold by Ar gas spraying.

|

Control Panel

| - The whole system is controlled by a 15.6" touch screen PC. The control or programmable parameters include:

- Induction coil oscillating speed

- Sample heating temperature for each sample

- Rolling speeds of top and bottom roller for each sample

- Pressing down amount for each rolling of each sample

- Rolling cycle for each sample

- The temperature of the heating plate on the rolling machine

- Time of lAr gas spraying

- The temperature of the rolled sample.

- 30 programs can be pre-stored for quick operation

- All data and curves can be download to an outside PC.

|

| Warranty | - One-year limited warranty with lifetime support

|

| Compliance | - CE certified

- NRTL certification is available upon request at the extra cost

|

| Dimensions | - L 300 x W1600 x H 1500 mm

|

| Net Weight | |

| Operation Demo Video |

|