Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

AXXIS – Co-Sputtering, Thermal Evaporation, & Electron Beam Techniques

Description

AXXIS™—Facilitates multiple deposition techniques and co-deposited films efficiently!

The University of Alberta uses our AXXIS for glancing angle depositions (GLAD).

Typical Applications

- R&D Thin Film Deposition

Process Options

- Heating

- Cooling

- Bias

- Ion Source for Substrate Cleaning/Assisted Deposition

Features

- 18" diameter x 15" deep cylindrical 304 stainless steel chamber

- Six radial process ports

- Hinged front-loading door

- Door- or port-mounted substrate fixtures

- Turbomolecular or cryogenic pumping

- Available with up to six TORUS® circular magnetron sputtering sources

- Available with up to 6-pocket 5.5kW electron beam source

- Available with up to three thermal evaporation sources

- Optional ion source

- Open framework

- Instrument rack

Optional

- Substrate fixture indexing and rotation

- Load lock

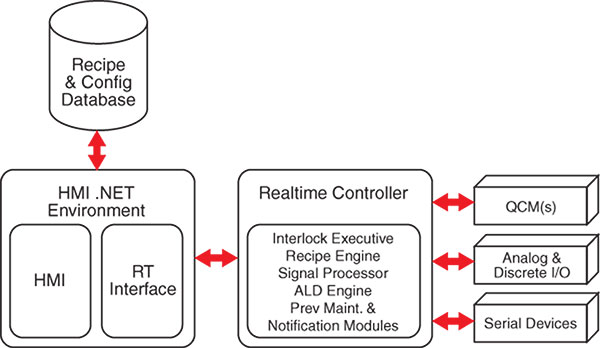

- Computer-controlled process automation