Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

CMS (Combinatorial Materials Science) Series – Advanced Research System utilizing Sputtering or Electron Beam Techniques

Description

Techniques Offered:

- Electron Beam Evaporation

- Thermal Evaporation

- Magnetron Sputtering

- Combinatorial Materials Science

Overview

- Extremely capable, advanced research tool

- Designed to accommodate specific thin film applications such as GMR, CMS, Semiconductor, Nanoscale devices, Photonics, and Photovoltaics

- Unique system design can be configured for true Ultra High Vacuum performance

- Field tested and proven design

Applications

- Giant Magnetoresistance (GMR)

- Combinatorial Materials Science (CMS)

- Semiconductor

- Superconductor

- Nanoscale devices

- Photonics

- Photovoltaics (PV)

- OLED

- Organic films

Features

Chamber

- Adaptable chamber, base plate, and substrate options

- 18" D x 15" H SS process chamber

Pumping & Gauging

- 1500 l/s Cryo pump

- Wide range vacuum gauge, atm to 1x10-10 torr

- High precision closed loop pressure control (both upstream and downstream for sputtering applications)

Substrate Handling

- Rotating substrate platen for up to 150mm (6") substrates

- Substrate heating to 800°C with quartz lamp heater

- Single or multi-wafer load lock with manual or computer controlled sample transfer

- High precision PID temperature control loop (when equipped with substrate heating)

Deposition Sources

- Pneumatically actuated source and substrate shutters

- Configurable with six or more magnetron deposition sources

- Cross contamination shielding (when applicable)

Quality & Safety

- Computer control with manual or fully automatic operation

- CE mark, UL listing, CSA, NRTL, and other industry recognized testing certifications available

- Extruded aluminum framework with enclosure panels

- Single service drop power distribution module

Options

Chamber

- UHV configuration

- 24" chamber upgrade

- Multi-process chamber cluster tool configurations

Pumping & Gauging

- Maglev turbo pump

- Dry pumping package

- Residual gas analyzer for in-situ monitoring of process gases or chamber constituents

Deposition Sources

- Available Linear multi-pocket UHV electron beam evaporation source (multi-technique options available)

- HV or UHV compatible magnetron sputter sources

Substrate Handling

- Rotating substrate platen for up to 200mm (8") substrates

- Substrate biasing for sample cleaning (typically RF plasma to remove native oxide layers)

- Substrate bias during deposition to influence features of film microstructure (such as crystal orientation), improve film densification, promote film adhesion, and promotes improved film homogeneity of co-sputtered alloy films

- Substrate heating to 1100°C with element style heater

- Substrate cooling (Liquid and/or LN2)

- Sample flip fixture for coating both sides of the substrate

- Film shaping tool (blade mounted to high precision computer controlled arm)

- Indexable magnetic field at substrate

- In-situ film analysis (Optical process monitor, RHEED, or spectroscopic ellipsometer)

Architecture Overview

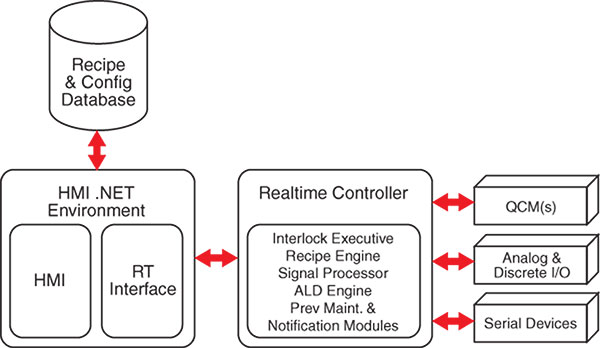

KJLC® eKLipse™ Control SoftwareKurt J. Lesker Company® eKLipse™ Controls Software is utilized on all KJLC platforms. The eKLipse™ controls platform utilizes a .NET application running on a Windows PC for its User Interface and Recipe Editor. Equipment automation is accomplished via a standalone Real Time Controller.

|