Induction Heater

| - Working Voltage: 208 - 240 V AC (Single Phases), 50/60Hz (50A air breaker is required)

- Input Current: 5 - 30 A Adjustable

- Output Frequency: 100 - 500 kHz Adjustable

- Max. Output Power: 6 KW

- Required Water Flow Rate: > 3 L/min

- Required Water Pressure: >=0.2 MPa (29 psi)

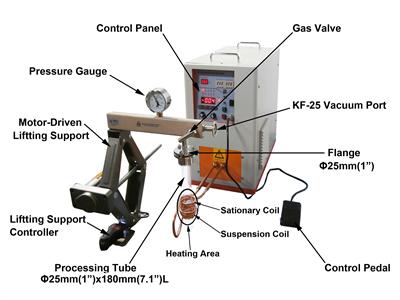

- Please click the picture on the left to see the detailed structure

|

Induction Heating Coil

for Levitation | - A multi-turn helical conical heating coil is used to balance the three-dimensional force

- Can successfully levitate electrically conductive material up to 10g

|

| Quartz Tube for Levitation | - Single End Opened Quartz tube: 25mm(OD) x 22mm(ID) x 180mm(L)

- Vacuum Sealing Flange for 1'' O.D tube with double high-temperature silicone O-rings

- 1/4'' barbed hose fitting, KF25 vacuum port, mechanical pressure gauge, and two needle valves are built-in on the supporting frame

|

Recirculating Water Chiller  | - Cooling Capacity: 722 kCal/h (2866 Btu/h)

- Max. Water Flow Rate: 16 L/min

- Temperature range to control: 2 - 35°C

- Please click the picture left for more details

|

Vacuum pump

| - One 156L/m Rotary Vane Vacuum Pump with Exhaust Filter is included

- Three KF25 quick clamps and one bellows are included for immediate use

- Max. Vacuum Pressure:

- 10^-2 torr by the mechanical pump

- 10^-5 torr by molecular pump

|

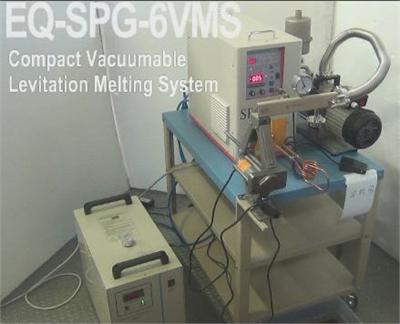

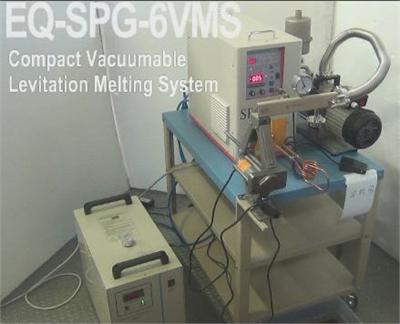

Work Station & Manipulator

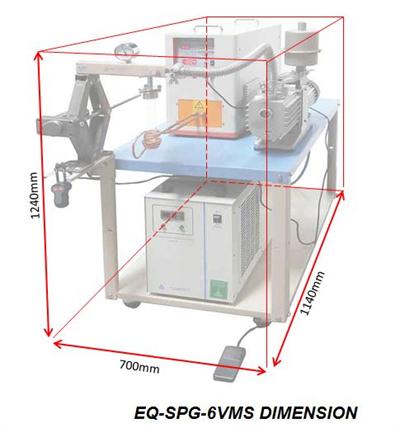

| - The induction heater, water chiller, and vacuum pump are integrated on a heavy-duty mobile steel cart: 600mm(L) x 800mm(W) x 600mm(H)

- Motor-driven manipulator provides rigid support and easy height adjustment

|

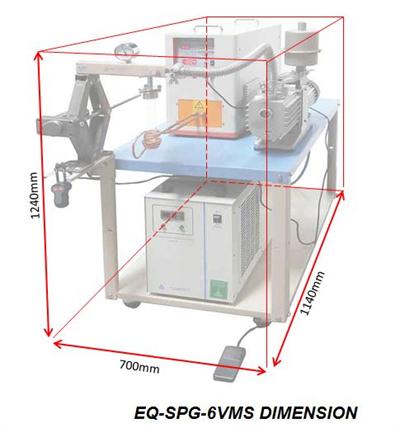

| Product Dimensions |  1140mm(L) x 700mm(W) x 1240mm(H) 1140mm(L) x 700mm(W) x 1240mm(H) |

| Warranty | - One year limited warranty with lifetime support

- Consumable parts such as processing tubes, o-rings and heating coil are not covered by the warranty

|

| Compliance | - NRTL or CSA Certification is available upon request at extra cost, please contact our sales representatives for a price quote. Certify standards include: 1) Induction heater: UL61010-1 & UL499; 2) Vacuum Pump: UL1450; 3) Water Chiller: UL61010 & UL1995

|

| Operation Video | Levitation Melting in air Levitation Melting with Inert gas Levitation Melting with Vacuum

|

Warning Click here to learn more about the installation of a gas regulator. Click here to learn more about the installation of a gas regulator. | - This system is suitable for Al, Mg, Copper, and its alloy with weight <10g。

- Please click here to learn how to set up the crucible for melting

- Attention: A pressure regulator must be installed on your input gas tank ( click picture below to review ) and have the output gas pressure set below 3 PSI at all times. Gas pressure exceeding over 3 PSI may cause irreversible damage to the furnace chamber.

- Never heat the furnace without flowing gas. Please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages. The flow rate for gases should be limited to < 200 SCCM ( or 200ml/min )

|

| Application Note: | - For customization inquiries, please complete the "Customize Induction Heating System Form" and return it to This email address is being protected from spambots. You need JavaScript enabled to view it.

|

| Net Weight | 200 lbs |

| Shipping Weight | 300 lbs |

| Shipping Dimensions | 48"(L) x 40"(W) x 49"(H) |

1140mm(L) x 700mm(W) x 1240mm(H)

1140mm(L) x 700mm(W) x 1240mm(H)

Click here to learn more about the installation of a gas regulator.

Click here to learn more about the installation of a gas regulator.