| Furnace Structure | - Double-layer steel casing with air cooling keeps furnace surface temperature lower than 60°C.

- High purity fibrous alumina insulation for maximum energy saving.

- Split cover with Interlock protection, cut the power if lid open during furnace heating process.

|

Power Input | 208-240 AC, 50/60 Hz single phase, 9 KW Max. (60A breaker required) |

Heating Elements | - 8 pcs 1Kw Halogen light tube, ( Dia. =10mm, L=300mm, Heated Length =200mm)

- Standard working life: 2000 hrs. ( depends on heating rate )

- The Halogen light tube is consumable. Please click picture left to order a spare one

|

Heating Zone | 12" length with 4" constant temperature zone within +/-5ºC uniformity |

Working Temperature | - 1100ºC Max. for < 10 minutes

- 1000ºC Max. for < 20 minutes (Note: if running longer time, furnace case will > 100°C, must use fan to cool the furnace case from outside)

- 800ºC Max. for < 120 minutes

- 600ºC Max. for Continuous

|

Max. Heating Rate | 50ºC/sec |

Cooling Rate | - Max. Cooling: 60ºC/min (Under vacuum: 200 m-torr), 117ºC/min (under atmospheric pressure)

- Lowest Cooling: 10 ºC / minute

|

Thermocouple | K type, the head of the thermocouple touches the Aluminum Nitride sample holder from underneath |

Temperature Controller

| - FA-YD808P-AG temperature controller is included.

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default DB9 PC communication port

|

Temperature controller (optional)

| |

Quartz Tube & Sample Holder | |

Vacuum Flange | - KF-D25 High Vacuum Flange is made of stainless steel with double hi-temp. silicone O-rings, needle valves, and a water-cooling jacket.

- It only requires water cooling in long-running times at temperatures > 600oC.

- Circulating water rate: 0.5 m3 /hr.

- The slide-out flange provides an easier way of loading, unloading the samples and other specific processes needed.

- Insert-able thermal-couple for accurate measurement.

|

Vacuum Pump (optional)

| - EQ-FYP vacuum pump is recommended for this furnace. The ultimate vacuum pressure in this system can be 10^-3 torr. Vacuum bellows and clamps are included in this package. Click here for the spec of EQ-FYP vacuum pump.

- Click here to view other models of pump and package.

|

Water Cooling (optional)

| - Cooling water is required.

- Please make sure the flow rate of cooling water is ≥ 10L/min, water temp. < 25ºC; pressure > 25 PSI.

- We suggest using the EQ-KJ5000 Series recirculating water chiller as a cooling system (please order separately at related products below) to save water.

- Warning: This RTP furnace's max dwelling time shall be less than 600 seconds at 1000ºC ~ 1100ºC with tap water, otherwise, O-ring may melt.

|

Flow-meter | One flow meter is installed on the front panel for adjusting gas flow from 16 - 160 ml/min |

Vacuum Gauge | A digital vacuum gauge with a measurement range from 10-4 to 1000 Torr is installed on the furnace. |

Vacuum Pressure & Gas Fitting | - Pressure can reach 50 more by using a mechanical vacuum pump with KF25 adapter

- Pressure can reach 10-4 torr by the molecular pump with KF25 adapter

|

Dimensions | - Flange closed: 1350mm(L) x 330mm(W) x 590mm(H)

- Flange opened: 1350mm(L) x 520mm(W) x 740mm(H)

|

Net Weight | 70 kg (150 lbs) |

Warranty | One year limited manufacturer warranty with lifetime support (Consumable parts such as processing tubes, o-rings and halogen lamps are not covered by the warranty, please order replacements at related products below). |

Laptop, software & WiFi Control(Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipe, record, and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available at an extra cost (up to $1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance | Please select the certificate in the options bar:

UL or CSA certificate (UL 61010) is available upon request at extra cost

|

| |

Optional | - You may combine the RTP furnace with a high vacuum station or gas livery system as a vacuum furnace or CVD system. Click pictures below to see details

- For achieving a fast cooling rate (< 10ºC/second), you may choose RTP furnace with sliding rail. Please click the picture below to see the details.

- You may order the pressure control module ( click picture below-right ) to keep the chamber at constant pressure

|

Application Notes

| - Tube furnaces with quartz tubes are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 MPa. Vacuum pressures may only be safely used up to 1000°CThe flow rate for gasses should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

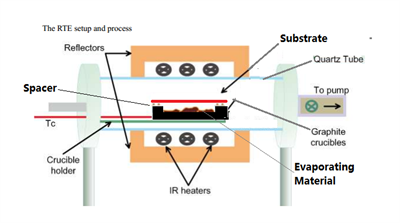

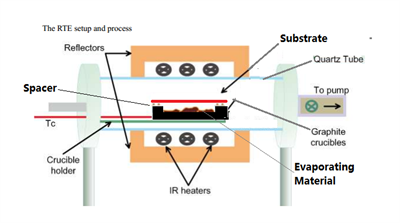

- This furnace also can be modified into an RTE, CSS or HPCVD furnace with a graphite crucible coated with SiC ( click Pic-left for detail how to set up an RTE processing by DIY )

- After CVD, the graphene must be transferred from the metal catalyst to another substrate for most applications. By using the graphene transfer tape, the residue can below.

|

Operation Instructions |

|