Auto-Sliding Split Tube furnace

two-zone heating is available upon request | - Input power: 208 – 240V AC, 1.2kW

- 1200°C Max. working temperature for < 60 minutes

- 1100°C Max for continuous heating

- High purity quartz tube 2"OD x 1.7"ID x 39.4" Length

- 30 segments programmable precision digital temperature controller

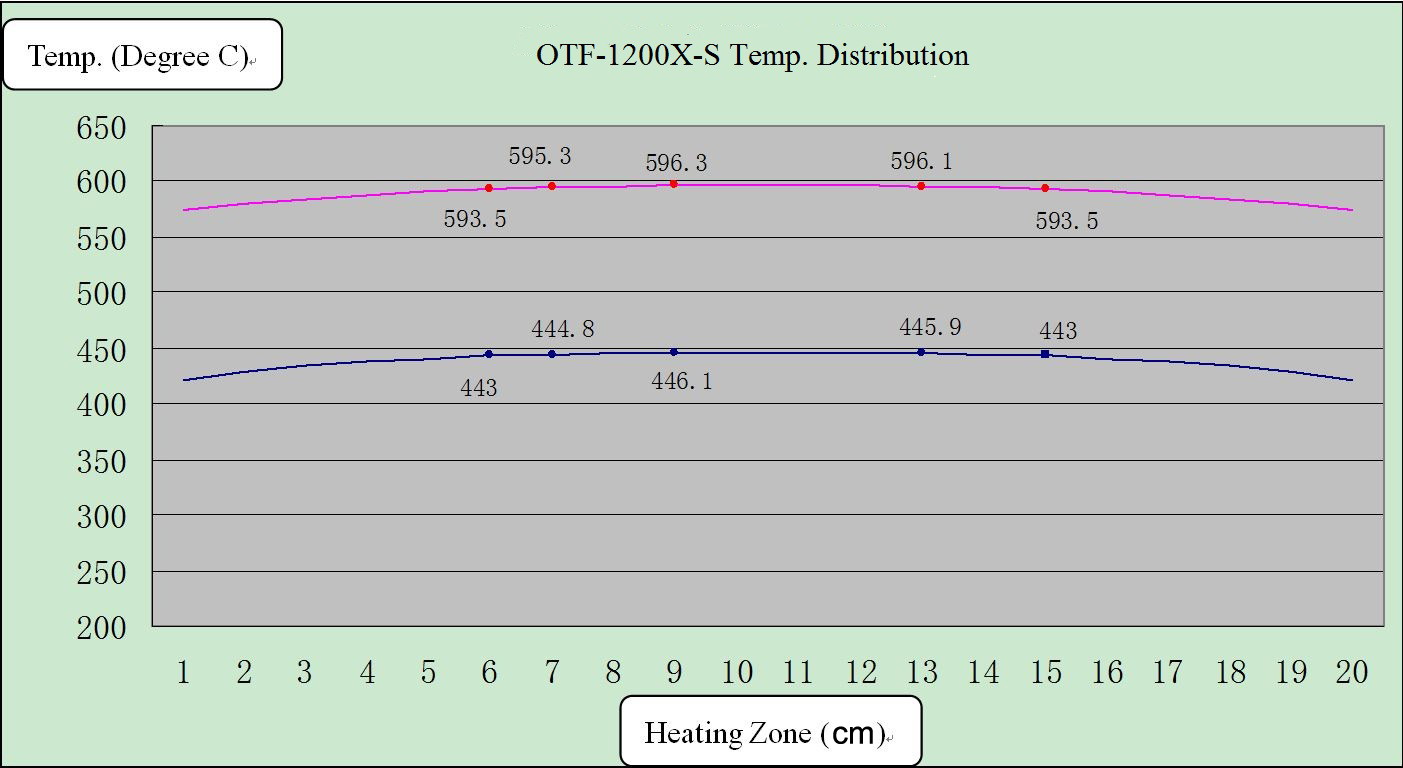

- 8" (200mm), single-zone. 2.3" (60mm) (+/-1°C) @ 1000°C The following picture shows the temp. distribution across the heating zone, please click to enlarge.

Temp. distribution profile Temp. distribution profile |

Plasma RF Generator | - Output Power: 5 -300W adjustable with ± 1% stability

- RF frequency: 13.56 MHz ±0.005% stability

- Reflection Power: 200W max.

- Matching: Automatic

- RF Output Port: 50 Ω, N-type, female

- Noise: <50 dB.

- Power: 208-240VAC, 50/60Hz

- Cooling: Air cooling.

|

Vacuum Flanges and Fittings | - The vacuum flange set is made of stainless steel 304.

- Left flange assembly includes a KF-25 vacuum port, two KF-25 quick clamps, a KF-25 right-angle valve, a KF-25 vacuum bellows, flange support, 3/8 O.D barbed fitting, and a needle valve.

- Right flange assembly includes a digital Pirani gauge, 1/4 O.D tube fitting, 1/4" feedthrough, a needle valve, and a KF-16 quick clamp set

|

Vacuum Pump  | - 208 - 240V / 50-60 Hz (750W Max.)

- 220 liters / M or 7.8 CFM

- Oil Mist Eliminator is included

- Max. vacuum: 3 X 10E-3 torr

|

Product Dimensions | - Overall Dimensions: 1500mm x 600mm x 1200mm (all system, L x W x H)

- Net weight: 350 lbs

- Shipping weight: 480 lbs

|

Oxygen Monitoring (Optional) | An Oxygen Sensor can be used to monitor the oxygen level of gas(es) used in CVD systems for preventing or reducing oxidation. Please click the picture below to learn more:

|

Options | - Please choose below gas delivery systems based on your budget ( click underlined or picture to order )

- The OTF-1200X-S50-PESL package adds gas mixing & delivery capabilities onto the furnace system by integrating four Channel Gas Mixing Station with PLC Touch Panel Control and Precision Mass Flow Meters. Please select this model from the Product Options above.

|

Warranty | One-year limited warranty with lift time support (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional)   | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables a user to edit temperature profile, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

|

Compliance

| - CE Certified

- NRTL (UL61010), CSA or TUV certification is available upon request at extra cost.

|

Operation Video |  |

Warning & Note  Click here to learn the installation of a gas regulator Click here to learn the installation of a gas regulator | - Tube furnaces with quartz tubes are designed for use under vacuum and low pressure < 0.2 bars / 3 psi.

- Vacuum pressures may only be safely used up to 1000°CThe flow rate for gasses should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation.

- MTI reserves the right to modify PECVD design at any time without notice but promise that quality will meet the specifications above

|