Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Compact Roll to Roll Coater w/ 160mm Max.Width For Battery Electrode Research - MSK-AFA-E200-UL

Description

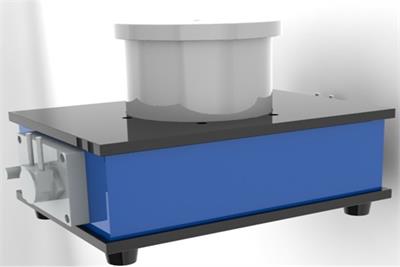

MSK-AFA-E200 is a compact Roll to Roll continuous coater for battery electrode sheets with a small footprint of 3.3'x2.1' for battery research labs. This system integrates the functions/ features of reeling in & out, slurry feeder, coating blade, baking oven, and final electrode winding (reeling in). It can coat electrode sheets up to 160mm in width and 500 meters in length automatically. Comparing with MSK-AFA-EI300, MSK-AFA-E200 lacks the controllable sheet tension function but comes in a much smaller size. SPECIFICATIONS:

Working Voltage | 208 – 240VAC, 50/60Hz, Single phase |

Max. Power Consumption | 3 KW |

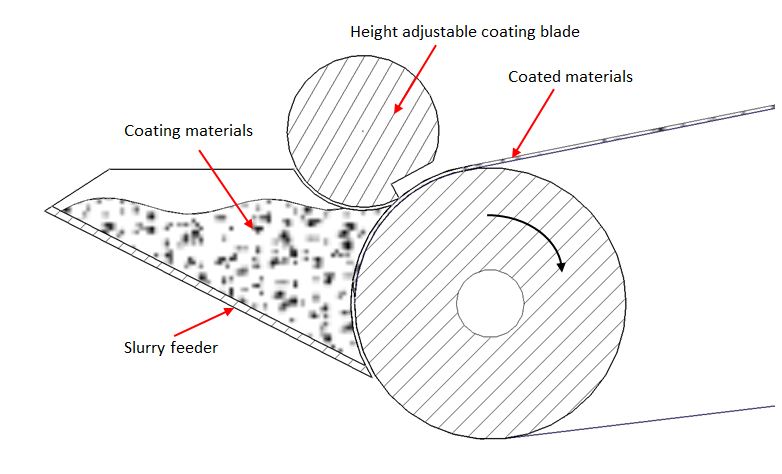

Coating Method & Precision |

|

50-160 mm Adjustable | |

Coating thickness | Usually 30~200μm Depends on different slurry viscosity |

Coating Speed | 0-200 mm / minute |

Drying Oven Temperature | 40-150°C +/- 1°C |

Reel-out/in System | 50mm (ID) |

Max. Rolled Diameter | 200mm (OD) |

Max. Coating Length |

|

Slurry Stirring | SS316 Moving Rod |

Guild Roller | The guild rollers are made of EPDM rubber. They are the consumable parts and suggested a replacement every year. Please click here to order the spare guild roller. |

Dimensions | |

Net Weight | 400 kg (882 lbs) |

Shipping Dimensions | 47" x 40" x 40" |

Shipping Weight | 1000 lbs |

Compliance |

|

Warranty |

|

| Operation Instructions Video |  |

| Application Notes |

|

| Optional |

Pic.1 Pic.1  Pic.2 Pic.2  Pic.3 Pic.3  Pic.5 Pic.5 |