Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

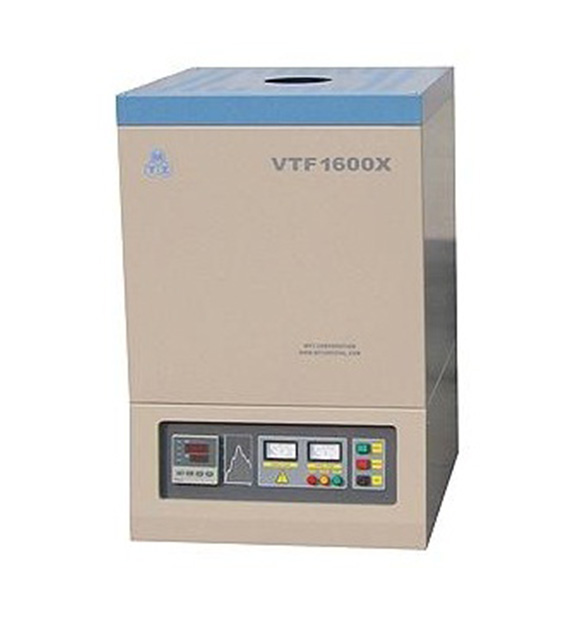

Crucible Melting Furnace 13"D x10"H up to 1600 C with 51 Segments Precision Controller - EQ-VTF-1600X

Description

Item Number:EQ-VTF-1600X

EQ-VTF-1600X Furnace is designed for melting metal and crystal growth via TSSG. The furnace has a vertical chamber with top load and a pulling equipment can be attached to the furnace easily. The furnace consists of high quality alumina fiber brick and MoSi2heating elements with chamber of 13" Diameter x 10 " high, and can be used up to 1600ºC (2912ºF). The Precision digital temperature controller with 51 segments programmable is built in the furnace.

Main Specifications

| |

Furnace construction |

|

Inside Chamber Size | 13" Diameter x 10 " high |

Standard Working Temperature | 1500ºC (2732ºF)( continuous ) |

Maximum Working Temperature | 1600ºC (2912ºF) ( < 3 hrs) |

Temperature Control | 51 steps programmable and auto control |

Heating Rate | 0~10ºC / min (suggestion at =< 5ºC) |

Temperature Accuracy | +/- 1 oC |

Heating Element | MoSi2 |

Working Voltage | AC 220V single Phase |

Max. Power | 9.5 KW |

Outside Size | 24" x 25"x 32.5" |

Net Weight | 180 Kg |

Dimension of shipment | 45" x 45" x 52" |

Weight of shipment | 400 Lbs |

Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty, please order the replacement at related products below.) |

|  |

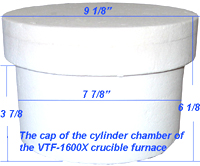

| Cap of the cylinder chamber | Top view of the cylinder chamber |

View Operation Manual

View Operation Manual  Download Catalog Flyer Customized mechanical pulling machine is available upon requestion.

Download Catalog Flyer Customized mechanical pulling machine is available upon requestion.

Warning: MoSi2 heating element is used in the high temperature under oxidizing atmosphere. It will form the SiO2 film which can keep the element from being melted. During the oxidizing process, the SiO2 protecting film is formed again when the element continues to be used. The MoSi2 heating element must not be used in the temperature between 400ºC and 700ºC for a long time, otherwise the element will be cremated under the strong oxidizing function in the low temperature.