Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

CVD Furnace 1

Description

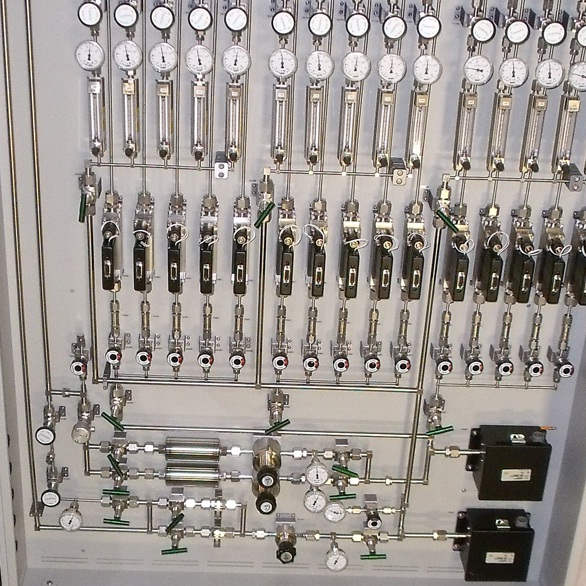

AVS Inc - builds full feature Chemical Vapor Deposition (CVD) furnace gas cabinets with capabilities for multiple gas delivery

AVS has built Chemcial Vapor Deposition (CVD) furnaces for the chemical vapor deposition (CVD) and chemical vapor infiltration (CVI) of a variety of materials, including silicon carbide, pyrolytic carbon, boron nitride, zinc selenide and zinc sulfide. AVS gas and vapor delivery systems coordinate mass flow controls and modulating valves to deliver reactant and carrier gases such as nitrogen, hydrogen, argon, methane, silicon tetrachloride, methyl trichlorosilane, boron trichloride, carbon dioxide, ammonia and others.

Precise control of temperature, atmospheric pressure, gas flows, exhaust stream, even rotary motion, is managed by the ACE™ control system. Decades of furnace design and heat control experience are applied to obtain the proper temperature ranges and uniformities necessary for predictable gas reactions. AVS retort assemblies and advanced differential pressure control technology keep reactant gases and by-products inside the retort, protecting Chemcial Vapor Deposition (CVD) furnace hot zones from contamination for extended service life.

To support our Chemcial Vapor Deposition (CVD) furnaces, AVS supplies reactant or carrier delivery systems, including weight-monitored liquid delivery systems, vaporizers, gas metering manifold systems and control cabinets. Waste stream management systems are also available, including dust collectors, condenser systems, collectors, gas burn-off stacks, incinerators or complete scrubber neutralization systems. AVS also offers leak detection and alert systems, such as hydrogen detection or hydrogen chloride sensors, all which can be fully integrated and interlocked to the customer’s emergency ventilation, SCRAM system or other safety evacuation systems.

Premier Solutions Pte Ltd / AVS Inc - builds full feature Chemical Vapor Deposition (CVD) furnace gas cabinets with capabilities for multiple gas delivery