Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

DNP Aluminum Laminated Film for Pouch Cell Case - DNP-ALF

Description

The DNP aluminum laminated film (91 um) is used as a casing material for the polymer Li-Ion battery, which is made in Japan

Specifications

Specifications

| Layers by Layer |

|

| Thickness | 91 μm ± 10% |

| Width and Length | DNP-ALF30: 120 mm ± 0.5 mm x 30m DNP-ALF50: 400 mm ± 0.5 mm x 50m DNP-ALF300: 400 mm ± 0.5 mm x 300m |

| Heat Seal Strength | 30 N / 15 mm or more |

| Laminate Strength ONy / ALM | 3.0 N / 15 mm or more |

| Laminate Strength ALM / PP | 5.0 N / 15 mm or more |

| Electrolyte Resistance ALM / PP | 4.0 N / 15 mm or more Dip Brazing 85°C, 24 hours |

| Surface quality | Mat finish |

| Fish Eye | 2mm or less in diameter (clear),1mm or less in diameter (colored) |

| Molding Depth | < 8.0mm |

| Electrical Insulating | Good |

| Hot Sealing Condition | 180-190°C |

| Moisture Vapor / O2 Transmission Rate | 200ppm / 5 years |

| Solvent Retention | Less than 5mg/m2 |

| Appearance | Within the sample of the limit |

| Slip Factor | CPP/CPP less than 1.0 |

| SDS | SDS for Aluminum SDS for Carbon Black |

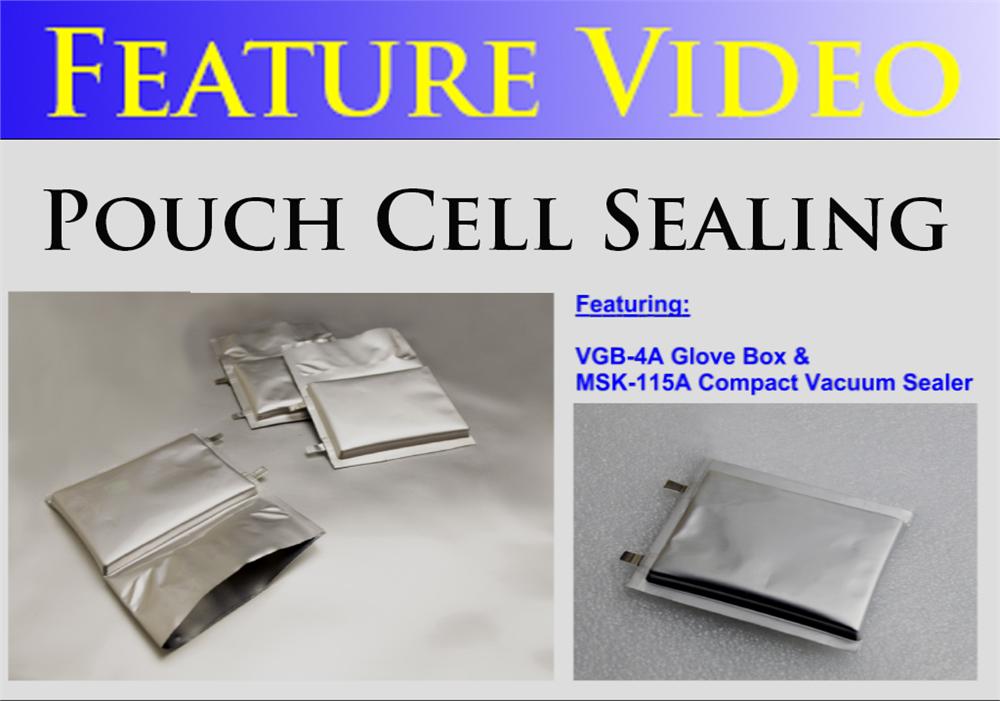

| Application Notes & Video | Click the picture below to see the finished polymer Li-Ion battery made by the heated sealer   |