| Working Voltage | 110VAC or 220VAC, 50/60Hz, Single Phase |

| Max. Power Consumption | 1.7KW |

Glovebox Chamber

| - Fully openable front window panel (tempered glass, 8 mm thick)

- Dimensions: 2400mm(L) x 800mm(W) x 930mm(H)

- Case Material: Stainless Steel 304

- Built-in fluorescent lamp

- Two shelves, 300mm L x 250mm W x 300mm H

- Two pieces of HEPA filters for particle size >0.3 μm

|

| Antechambers | - Large Antechamber Dimensions: 360mm(Dia.) x 600mm(L)

- Small Antechamber Dimensions (for tools): 150mm(Dia.) x 300mm(L)

- Max. vacuum level: 100 Pa

|

| Obtainable Purity Level | - Water concentration: <1 ppm (20°C, 1 atm)

- Oxygen concentration: <1 ppm (20°C, 1 atm)

|

| Working Gas | - Operating gas: Inert gas such as N2, Ar, He

- Regenerating gas: Mixture of H2 (5%) and Operating gas

- Note: If you use Ar gas, please make sure the inside equipment is Ar gas compatible

|

| Gas Purification System | - Auto regeneration process with user defined parameters.

- Built-in Regeneration Temperature Controller.

- Automatically purging function is built-in for quickly reducing O2 < 100ppm & H2O < 100 ppm before cycling.

- The automatic pressure control system is built in to keep the pressure at a constant level.

- Purification Cylinder: made of BASF antioxidant materials (Na86((AlO2)86(SiO2)106.XH20, 5 kg) and UOP water adsorbent materials.

- Moisture removal capacity: 2 kg

- Oxygen removal capacity: 60L

- Stainless steel pipe connection

- Blower: Flow Rate: 90m³/h

|

| Filter System (optional) | - One Organic Solvent Filter System filled with replaceable activated carbon (5.2kg) is optional

- Carbon and solvent vapor filters are available upon request at the extra cost for flammable vapor

|

| Control system | - Siemens PLC control system with 6" touchscreen display

- Water concentration: 0 - 1000 ppm

- Oxygen concentration: 0 - 1000 ppm

- Auto pressure control -5 - 8 mbar

|

| Feedthroughs | - Power feedthrough is included.

- power extension board with 5 outlets, 15A max.

- Can be 110VAC or 220VAC depending on the input source

|

Vacuum Pump

| - 240L/m Heavy Duty Double Stage Rotary Vane Pump for faster gas exhaust

- Vacuum rate: 7.8 cfm

- Lowest pressure: 0.4pa

|

| Gloves | - Two pairs of NORTH Butyl glove is included

- Protection against toxic materials

- 8" Dia.x 32" Long

|

| Product Dimensions | 3235mm(L) x 1040mm(W) x 1860mm(H) (127" x 41" x 73") |

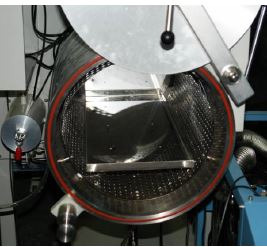

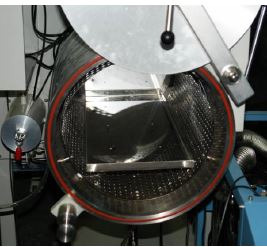

| Heatable Antechamber (optional) | - Heatable Antechamber: 200C max., DN385×588mm (L), available ( Pic. 1-2)

- Two large ante-chambers with central isolating door is available upon request (Pic. 3 )

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3 |

| Shipping Dimensions & Weight | 2 pallets, 1800 lb total weight #1: 86"x41"x84" #2: 86"x41"x83" |

| Operation Instructions |

|

| Warranty & Compliance | - One Year limited warranty with lifetime support

- Rusting and damage due to improper storage or maintenance are not covered by warranty

- Gloves are consumable items and are not covered under warranty

- NRTL or CSA certification is available upon request at the extra cost

|

| Application Notes & Warnings | - The interconnections between the glovebox chamber and the gas purification system must be unimpeded during the purification cycles.

- The use of corrosive gasses is prohibited as they will damage the water and oxygen sensors.

- Regularly perform regeneration to maintain optimum purification efficiency.

- The O2 removing rate is largely dependent on the type of purging gas used. For a faster chamber purging process, Nitrogen is preferred over Argon due to its lighter mass.

- Corrosive liquid, such as LiPF6, must be remain sealed in a container inside the glove box.

- The glove box may connect with the tube furnace upon request

- You may order vacuum transportation jar to deliver the air-sensitive sample into or out of the glovebox.

|