Furnace Structure  | Single heating zone

- High purity Al2O3 insulation chamber guarantees excellent temperature uniformity.

- Cooling fans are installed at the bottom of the furnace to ensure efficient ventilation.

- Sliding flange assembly is made of stainless steel.

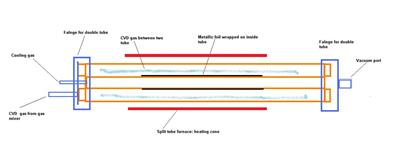

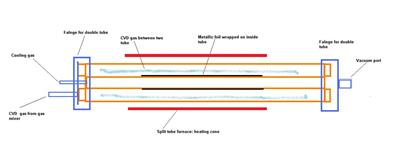

- Dual quartz tube:100mm Dia. exterior tube and suspended by 80 mm Dia. interior tube. Metallic foil (Graphene Growth Substrate) will be wrapped around inside the tube surface for CVD reaction

- Heating zone length: 440mm

- Constant temperature heating zone length: 120 (±1°C) @400~1100°C

| Dual heating zone

|

Power

10 feet power cable with no plug (ask a licensed electrician to do the plug) | Single heating zone

Power: 208-240VAC, 50/60Hz, single phase, 2.5KW ( 20A Breaker required) | Dual heating zone

Power: 208-240VAC, 50/60Hz, single phase, 4 KW ( 50A Breaker required) |

| Heating Temperature | - Max. Temperature: 1100°C

- Continuous Temperature: 1000°C

|

| Heating & Cooling Rate | Max. heating and cooling rates depend on working temperature. Please click on the tables below to see Max. heating & cooling rate varies at different temperatures range.

( You shall calibrate temperature and heating cooling rate at your working condition before use )

Heating plot Heating plot  Cooling plot Cooling plot |

| Fused Quartz Tubes | -

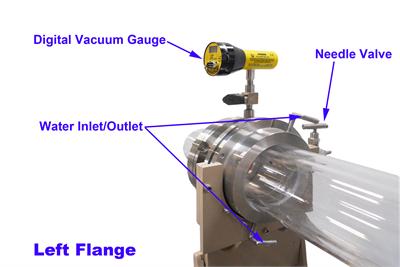

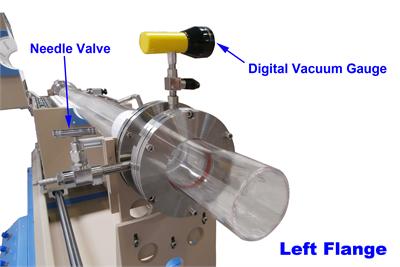

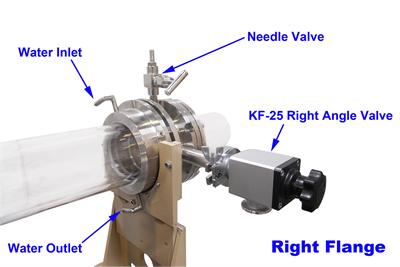

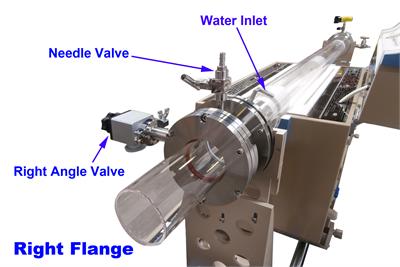

High purity quartz tube: Two pairs of vacuum-sealed flanges with water cooling jackets and stainless steel needle valves

- Outside tube EQ-QZTube-101D-1400: OD:4"x ID: 3.8" X 55" Length (OD 100 x ID 96 x 1400 mm )

- Inside tube EQ-QZTube-80D-1800: OD:3.15: x ID x 2.95" x 70.8" Length (OD 80 x ID 75 x 1800 mm

|

| Vacuum Flanges | Using dual-tube for inducing CVD growth on metal foil (wrapped around interior tube surface):

Please click for a related article: "Roll-to-roll production of 30-inch graphene films for transparent electrodes " - 1-1. Shown below, one pair of SS304 flanges to seal both the outside tube and space between the outside tube and inside the tube (this space is considered as a reaction chamber).

- 1-2. Leave both ends of the inside tube open for gas cooling.

Ultimate vacuum pressure: 10^-2 torr (by mechanical pump)

10^-5 torr (by turbo molecular pump) |

| Temperature Controller | - PID automatic control with 30 programmable segments for precise control of heating rate, cooling rate, and dwell time.

- Built-in over-temperature alarm and protection allow for operation without any attendant.

- Over-temperature protection and alarm allow for operation without attendant(s).

- +/- 1 ºC temperature accuracy.

- RS485 Communications Port.

- Advanced Temperature Control (Optional)

- MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar. Click for detailed information about the MTS02-Y software kit.

- You may upgrade the temperature controller to the Eurotherm 3504 Temperature Controller which is fully compatible with LabVIEW. This package includes a Eurotherm 3504 programmer, a communication cable (RS485 - USB) and a software CD. Click the pic below to view the full spec of the Eurotherm 3504 temperature controller.

|

Mass Flow Meters & Gas Mixing Station  | - 4 precision mass flow controller ( MFC) with digital display and adjusting knob are installed on the left bottom case to control gas flow rate:

- 4 Gas channels (contact MTI sales if need more)

- MFC 1: Control range from 0~100 SCCM

- MFC 2: Control range from 0~200 SCCM

- MFC 3: Control range from 0~200 SCCM

- MFC 4: Control range from 0~500 SCCM

- Flowing rate accuracy: ±1% FS

- Gas inlet and outlet: 1/4" Swagelok tube connector

- One 80mL gas mixing tank is installed in the bottom case

- Each gas channel has a stainless steel needle valve for easy on/off

- The flow rate is adjustable from the MFC panel

|

Vacuum Pump Station and valves  |   |   |

Water Cooling Function

| - Water cooling on the flange is mainly for cooling down the o-ring inside the flange to ensure the best-sealed chamber at high temperature:

- Water cooling flanges require >= 10L/M water flow.

- You may use tap water as the coolant, but we strongly suggest you use a recirculating water chiller for environmental considerations. Please click the thumb left to order the water chiller at extra cost

|

| Optional Parts (building up a single tube furnace) | - You can build up an 80mm Dia. single tube reaction by ordering extra sealing flanges and install them onto the interior tube:

- Left side flange: Barb fitting with needle valve as gas inlet and 1/4'' feedthrough fitting for the customer to insert a measuring sensor (e.x. an insertable thermocouple for temperature calibration)

- Right side flange: KF25 fitting with mechanical gauge and vacuum release valve

(click to enlarge the picture) (click to enlarge the picture)  click here to choose a crucible click here to choose a crucible

|

| Dimension | - Furnace: 550 x 380 x 520mm

- Bottom mobile case x 2: 600 x 600 x 600mm (one for gas mixing station and the other for vacuum pump)

|

| Shipping | - Shipping Weight: ~800 lb

- Shipping by freight with three pallets

- The crating fee will be applied

|

| Warranty | One year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order replacements at related products below). |

| Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables a user to edit temperature profiles, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

| Compliance | - CE Certified

- NRTL (UL61010) or CSA certification is available upon request at extra cost.

|

Application Notes

Click here to learn the installation of a gas regulator | - Tube furnaces with quartz tubes are designed for use under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 Mpa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube

- Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

- Click here to learn How to set up a quartz/ ceramic tube and vacuum flange for MTI Tube furnace.

- One slide stopping clamp is included for holding the position of the furnace.

- After CVD, the graphene must be transferred from the metal catalyst to another substrate for most applications. By using the graphene transfer tape, the residue can below.

|

| Warning | - Fast sample cooling can be achieved by sliding the heating chamber away. Please wear protective gears such as heat resistant suit & gloves if you intend to do so. DO NOT TOUCH THE TUBE SURFACE WHEN IT IS HOT!

|

| Operation Video |

|

Heating plot

Heating plot  Cooling plot

Cooling plot

(click to enlarge the picture)

(click to enlarge the picture)