Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Epi282 Series Deposition Stages

Description

EpiCentre 282 UHV Manipulator Stages

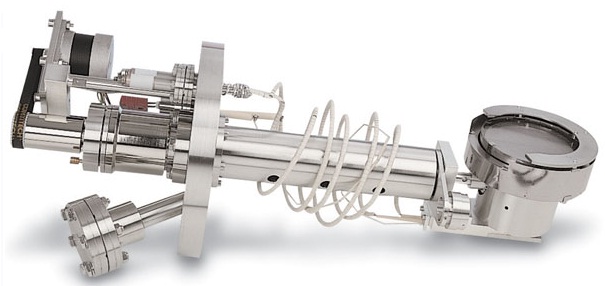

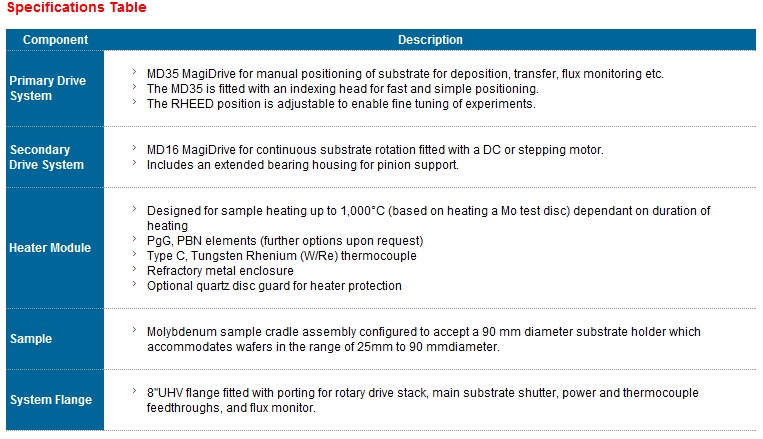

The Lesker EpiCentre 282 is a full heating and rotation stage intended primarily as a retrofit instrument for molecular beam epitaxy systems such as the V80H. This component differs from the Lesker EpiCentre 100 and 346 in that it supports the substrate at a right angle to the general manipulator Z axis. Two axes of rotation provide continuous azimuthal rotation for the sample and a limited primary rotation for substrate orientation.

An awareness of existing right-angled manipulator design drove a complete rethinking of the concept of this stage. By stacking two MagiDrive rotary feedthroughs we are able to achieve a dual axis, concentric rotation system which eliminates the head positioning gear train typically used by other manufacturers. By incorporating the Lesker EpiCentre heater module technology into this component, we are able to improve on ultimate temperature capability, uniformity and reliability.

System Design Philosophy

The azimuthal drive is achieved through a bevel gear train actuated by the MD16 MagiDrive. Particular attention has been paid to the design of this section of the instrument, as it has conventionally been the source of premature failure. The gear train is supported in a precision housing that ensures the gear pitch distance does not reduce for increased temperature. The substrate cradle drive mechanism is positioned further from the hot zone and uses large ball races in an arrangement tolerant of the thermal stresses. This all results in low radial run-out of the cradle during rotation, which is important for serious RHEED measurements.

Stage Positioning

The Lesker EpiCentre 282 may be fitted with a simple manual tilt positioning selector. Alternatively, a fully automated system is available. Manual positioning is achieved by thimble adjustment of an MD35H MagiDrive. A positioning ring with an external spring-loaded pin is attached to the drive. Releasing the pin enables the drive to be rotated to a number of pre-defined positions. These ensure simple and repeatable locking of the stage for sample transfer, growth, flux monitoring and RHEED. The RHEED position may be finely tuned to allow for chamber geometry variations. The automated option provides stepper motor control over the MD35H. Bakeable switches protect the system from travel beyond its limits and provide an absolute homing point. When coupled to the KZSMC1 series motor controller this system allows precise positioning to be achieved throughout the desired range.

Heater Modules

The Lesker EpiCenter 282 series is available with the same 100 series heater element technology including PgG (Pyrolytic graphite coated Graphite) and PBN (Pyrolytic Boron Nitride coated graphite). These heater elements offer the best ratio of heat radiating surface to gap and therefore run at lower temperatures for a given power transmission.

The heater module is also available with a quartz guard to protect the element during sample transfer. The heater element power graph plots the required Volts or Amps (left scale) to reach temperatures ranging from 400°C - 820°C. The graph then illustrates the total power (Watts) required for the same temperature range (right scale). Below this the heater resistance is plotted versus temperature. Other heater configurations can be provided on special request.

Substrate Spin, Positioning, Temperature Control, and Power Supply Options

The Lesker EpiCentre 282 may be fitted with DC or stepper motors for continuous substrate rotation. Both options may be controlled using the motor control options detailed on their respective pages. The heating element is designed to match the temperature controller and Glassman supply detailed on the controllers page.

Lesker Epi282 Series Deposition Stages