| Working Voltage |

- 110 or 220 VAC switchable, 50/60 Hz, single phase

- Max power: 1.5 kW

|

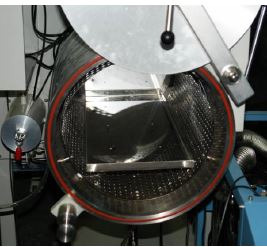

Glove Box Chamber

|

- Case Material: Stainless steel 304 with 3 mm thickness

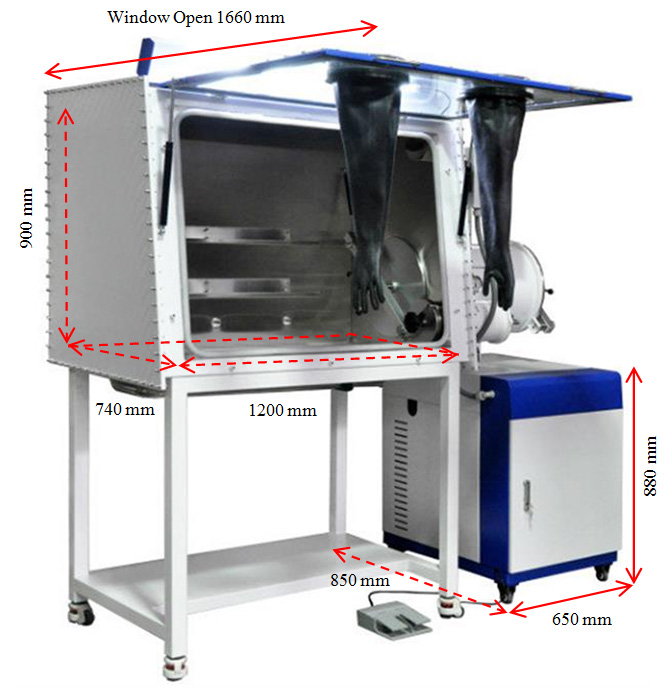

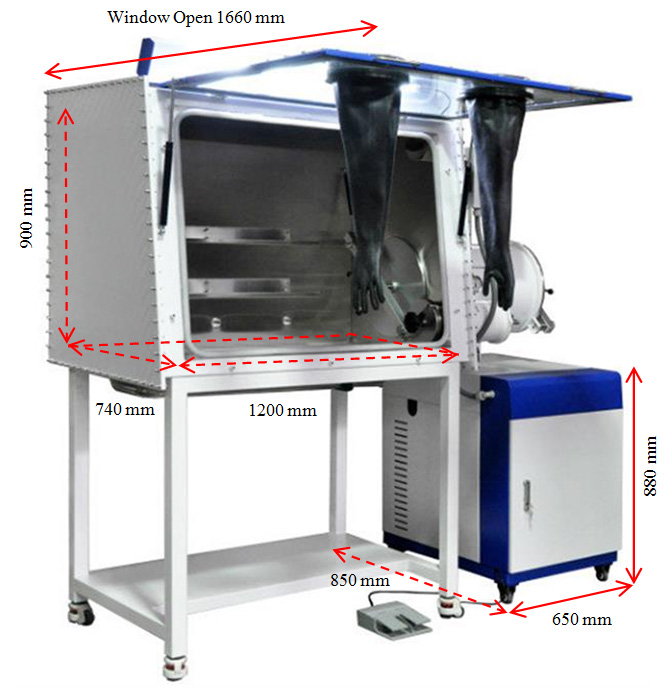

- Chamber dimension: 1200 mm L x 740 mm W x 900 mm H

- Openable front window panel (tempered glass, 8 mm thick)

- Hinged type door for easy load devices inside the glovebox

|

| Chamber Condition |

- Regeneration Temperature Controlleris built-in for automatically regenerating the filters

- Automatically purging function is built-in for quick reducing O2 < 200ppm & H2O < 50 ppm before recycling.

- The automatic pressure control system is built in to keep the pressure at a constant level.

- Water concentration: <1 ppm (20 °C, 1 atm)

- Oxygen concentration: <1 ppm (20 °C, 1 atm)

|

| Leak Rate |

- <0.05 vol% / hr (depending on oxygen concentration inside the glove box)

|

| Antechamber |

- Antechamber dimension: 360 mm Dia. x 600 mm L

- Small chamber dimension (for tools): 150 mm Dia. x 220 mm L

|

| Heatable Antechamber (optional) |

- Heatable Antechamber: 200C max., ID 385×588mm (L)

Pic. 1 Pic. 1  Pic. 2 Pic. 2

|

| Optional |

- Loading and unloading device from the front door is much easier than ever! A vacuum-sealed jar is available for air-sensitive sample transporting ( clicking Pic. 1 to order )

- KF100 port with a blinding plate is optional to connect a tube furnace up to an MTI tube furnace (Pic. 2-3)

Pic. 1 Pic. 1  Pic.2 Pic.2  Pic. 3 Pic. 3  Pic. 4 Pic. 4

|

| Working Gas |

- Operating gas: Inert gas such as N2, Ar, He

- Regenerating gas: For regenerating both oxygen and H2O remover, use a mixture of H2 (5-10%) and operating gas

|

| Gas Purification System |

- Automated regeneration process

- Automated Water and oxygen removal

- Purification cylinder: made of BASF R3-11 Copper Catalyst and Lindy Molecular Sieve

- Pipeline: 304 stainless steel, KF40, and KF25 ports

|

| Ports & Fittings |

- Total three KF40 ports on the back of the glove box

|

| Filter System |

- Inlet and outlet filter can eliminate particle size > 0.3 μm

- Carbon and solvent vapor filters are available upon request at the extra cost for flammable vapor

|

| Pressure Control System |

- Automatic pressure control by PLC for the Glove Box Chamber

- Pressure range: +/- 12 mbar

- Manual pressure control is allowed via a foot pedal

|

| Purging System |

- An automatic purging system allows easy operating and reduces gas consumption

|

| Control System

|

- Siemens PLC control system with 7" touchscreen display

- Water concentration: 0 - 1000 ppm with an accuracy of 0.1 ppm

- Oxygen concentration: 0 - 1000 ppm with an accuracy of 0.1 ppm

- Pressure: -12 to 12 mbar with an accuracy of 0.01 m-bat

- Records for total hours of operation, total regeneration times, time since last regeneration

|

Pump

|

- 240 L/m heavy-duty double stage rotary vane pump for faster gas exhaust

- Vacuum rate: 240 L/m (8.5 cfm)

|

| Gloves |

- A pair of 9 3/4" butyl gloves is included for immediate use

|

| Lighting |

- Built-in fluorescent lamp

|

| Dimension |

- Product Dimension: 2000 mm L x 1000 mm W x 1880 mm H (79" x 40" x 74")

- See the pictures below for detailed dimensions

|

| Shipping Dimension |

|

| Shipping Weight |

|

| Compliance |

- NRTL certification is available upon request with extra cost

|

| Warranty |

- One-year limited warranty with lifetime support

- Rusting and damage due to improper storage conditions or maintenance are not covered by a warranty

- Gloves are consumable items and are NOT covered by a warranty

- The oxygen sensor is consumable, NOT covered by warranty. Please use the videos below for properly 1) Replacing a worn unit and 2) Storing the sensor to ensure maximum longevity when not used

|

Operation Instructions

& Video |

|

Application Notes & Warnings

|

- The interconnections between the glovebox chamber and the gas purification system must be unimpeded during the purification cycles.

- The O2 removing rate is largely dependent on the type of purging gas used. For a faster chamber purging process, Nitrogen is preferred over Argon due to its lighter mass

- Regularly perform regeneration to maintain optimum purification efficiency.

- The O2 sensor is consumable and its expected lifespan is around one year. We supply a replacement O2 sensor, please click the underline and just order the sensor.

- The use of corrosive gases is prohibited as they will damage the water and oxygen sensors!

- Corrosive liquid (such as LiPF6 electrolyte) must be remain sealed in a container inside the glove box. Otherwise, liquid vapor may condense and corrode the steel chamber and purification pipeline.

- We can connect various tube furnaces with the glove box for processing air sensitive materials

- You may order a vacuum transportation jar to deliver the air-sensitive sample in or out glove-box

|

| Heatable Antechamber (optional) |

- Heatable Antechamber: 200C max., DN385×588mm (L), available ( Pic. 1-2)

- Two large ante-chambers with central isolating door is available upon request (Pic. 3 )

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3

|