Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Graphene Foam Sheet (spongy graphene, 2" x 2" x 1.2 mm) for Lithium Air Battery Research - GF-2212-LD

Description

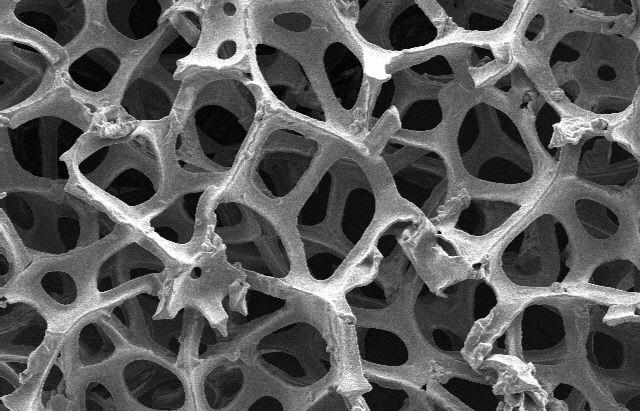

The 3D Graphene Foam is made via chemical vapor deposition (CVD) processing. In course of CVD fabrication of graphene hydrogen and methane gases are introduced into a furnace that heats to 1000° Celsius. In the furnace is a nickel or copper film which captures a mono or multi-layer or graphene as the furnace is heated and the methane decomposes. To create CVD Graphene Foam, instead of using a thin sheet of nickel to capture graphene, nickel or copper foam is used. The metal foam captures graphene in a similar foam structure. The metal skeleton is then etched away and left is a visible, porous 3D graphene foam structure. This structure has a high surface area, which opens several exciting applications for Graphene Foam while maintaining most of two-dimensional graphene’s properties1. CVD processing of Graphene Foam opens a cost-effective route for engineering a new class of ultra-light, highly conductive graphene-based materials with exceptional mechanical strength, flexibility, and elasticity.

| |

Application Notes |

|