Furnace Structure

| - 1700°C Max. vertical tube furnace is built on the bottom with the separated temperature control unit

- Alumina processing tube, vacuum-sealed flange with valves, vacuum gauge, thermal blocks are included

- The gas quenching chamber is built-in the top of the furnace with a vacuum-sealed lifting rod

- Quench sample up to 50mm dia, x 65 mm L under inert gases and vacuum

|

Gas Quenching Chamber

| - The quenching chamber is made of SS304, and vacuum sealed with two observation windows on the door, which can reach the vacuum level up to 10-5 torr via a turbopump

- The sample can be loaded from the chamber via a hook and tungsten wire, then put the sample into processing tube

- The lift rod is moveable up-down manually via Magnetic Fluid Sealed Swivel Coupling (Lectric lifting available)

- The electric gate valve is built on the bottom of the chamber to block radiation from the heating tube

- 1/8 gas inlet and gas outlet port are installed on the chamber

- The lift rod will bring the heated sample from the heating zone to the quenching chamber, then close the gate valve and compressive gas will below the heated sample to quickly cooling

|

Power Input | - Single Phase, 220V AC +/- 10%, 50/60 Hz

- Max. 4000W (4 KW)

- 20A air breaker required

- 10 feet length 10-3 AWG heavy duty UL approved power cable is included. Extra length cable can be ordered by click picture below-left

- The plug is not included. Browse our catalog for compatible plugs or obtain one from a local hardware store

|

Working Temperature | - Max. working temperature: 1700°C (3092°F) for < 1 hours

- Continous working temp.: 800-1600°C (3002°F)

|

Heating / Cooling Rate | - 5°C/min above 1200°C

- 10°C/min below 1200°C

|

| Heating Elements & Heating Zone | - 4 pcs of U-shaped 1800 grade MoSi2

- Heating Zone Length: 130mm

- Constant Temperature Zone: 60 mm +/- 5°C

|

Temperature Controller  | Two digital Temperature controllers are installed in the furnace system: (1) Eurotherm 3000 is used as furnace temperature control

- 24 segment programmable with ± 0.1℃ accuracy

- Alarm for over-temperature, The temperature deviation,and thermal couple broken

- RS485 communication port installed for PC operation, and software is included, which will record data (1 per/minute)

- Thermal couple for temperature control: B type

(2) YD518 controller (48*48mm, MET certified)) is used as the temperature monitoring for extra protection

- The extra B type of thermal couple is installed inside the furnace for monitoring

- In case that control T/C is broken and the temperature controller does not work, the controller will cut-off power

|

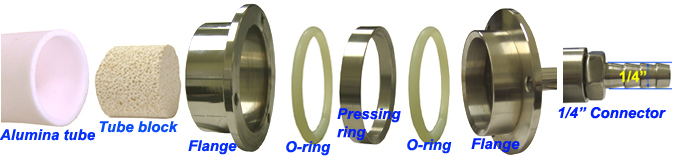

Processing Tube

| - 99.8% High purity Al2O3 Ceramic, ID: 54mm; OD: 60 mm x Length 850 mm

- Two fibrous ceramic tube blocks are installed on both top and bottom flanges for blocking heat radiation from the inside tube

|

Vacuum Sealing and Valve | - Vacuum flanges made of SS304 for processing tubes are included.

- KF25 vacuum port for connecting a vacuum pump

- Vacuum pressure can reach 50 mTorr by a quality mechanical vacuum pump and 10^-5 torr by turbo molecular pump. Please click the picture below to see the flange assembling details.

- Gas inlet and out port with needle valves are included, which accept 1/4"OD stainless steel gas pipe.

- Optional:

|

Dimension | |

Net Weight | |

Shipping Dimensions | |

Shipping Weight | |

Warranty | One-year limited warranty (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Compliance | - CE Certified

- NRTL or CSA certification is available upon request at extra cost.

|

Warning | MoSi2 heating element is used in high temperature under an oxidizing atmosphere. During the oxidizing process, the SiO2 protective film is formed again the heating element from melting during sustained use. The MoSi2 heating element must not be used in the temperature between 400°C and 700°C for a long time, otherwise, the element will be cremated under the strong oxidizing atmosphere at low temperatures. |

Application Notes

Click here to learn more about the installation of a gas regulator. | |

Operation Instructions

&

Video |

|