Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

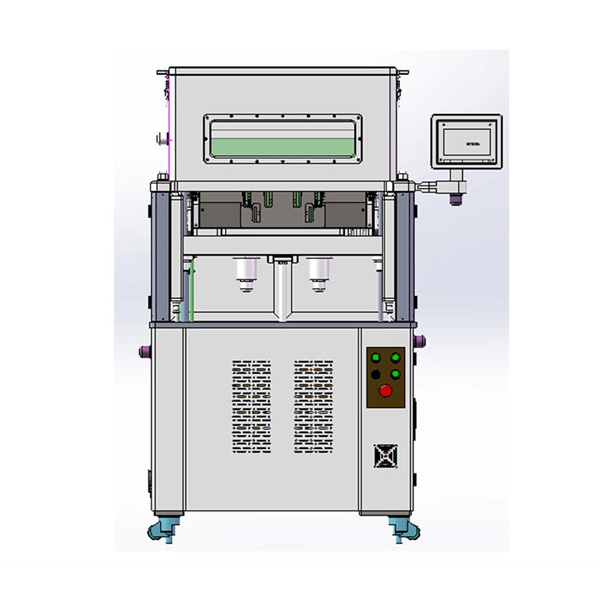

Large Vacuum Sealer w/ Electrolyte Injection and Vacuum Standing for Pouch Cell up to 500x350 mm- MSK-115A-H

Description

MSK-115A-H is a vacuum sealer with the multi-functions, including electrolyte injection, vacuum standing (electrolyte diffusion), and vacuum Sealing for large size pouch cell batteries. This device could be used in a dry room.

MTI has granted the patent 201822101349.0 for the Pouch Cell Sealing Machine integrated with Electrolyte Injection MSK-115A-H since December 2019.

SPECIFICATIONS:

Advanced Features |

|

| Input Power |

|

| Working Gas |

|

| Electrolyte Dispenser |

|

| Pouch Size Adaptability | |

| Vacuum Degassing |

|

| Sealing Die |

|

| Sealing Pressure |

|

| Sealing Temperature |

|

| Sealing Time |

|

| Machine Dimensions |

|

| Net Weight |

|

| Warranty |

|

| Compliance |

|

| Operation Manual & Video | |

| Application Notes |

|