Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

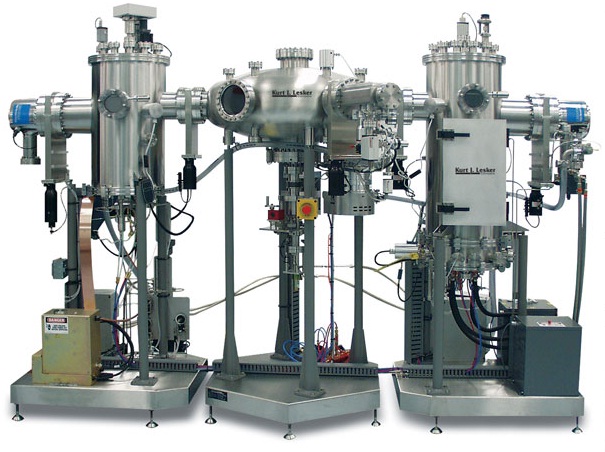

LUMINOS - Manual Cluster Tool

Description

LUMINOS™— Multi-chamber thin film deposition and analysis manual cluster tool system for R&D applications requiring in-vacuum substrate transfer between chambers.

Penn State University uses Lesker LUMINOS™ to deposit multi-layered PVD and CVD thin films.

- Radial Distribution Center Chamber enables 6 to 8 process modules to be connected, accommodates substrates up to 4" x 4"

Typical Applications

- Multi-Chamber for OLED/PLED R&D

- Multi-Chamber for Device Fabrication

- Thin Film Deposition and Analysis

Deposition Techniques Available

- Magnetron Sputtering (RF or DC)

- Thermal Evaporation of Metals & Inorganics

- Thermal Evaporation of Organics, Including OLED/PLED Applications

- ALD

- Electron Beam Evaporation

Process Options

- Heating

- Cooling

- Bias

- Ion Source for Substrate Cleaning/ Assisted Deposition

Features

- Substrate entry and exit load lock and sample preparation chamber

- Radial Distribution Center (RDC) Chamber

- 304 stainless steel 8-way 36" diameter chamber

- Manual rotary sample transfer device

- Motorized linear and Z-shift sample transfer devices

- Pneumatic isolation valves between radial process chambers

- Organic Evaporation Chamber – Available with up to 9 low-temperature organic evaporation sources

- Metal Evaporation Chamber – Available with up to 4 thermal evaporation sources

- Mask-Changing Module

- Manual Z-shift sample transfer device for mask exchange

- 10-mask storage capacity with mask holders

Optional

- Sputter deposition chamber

- Reactive plasma cleaning chamber

- Computer-controlled process automation

For over 20 years, Kurt J. Lesker has designed, manufactured, assembled, programmed, and tested hundreds of thin film deposition systems for both research and production applications. Kurt J. Lesker four clean assembly areas, located at their US and UK facilities, provide the necessary environment for system assembly and testing. All seals, welds, flanges, and chambers are helium leak checked and inspected to ensure vacuum integrity prior to system assembly. These components are then professionally assembled by Kurt J. Lesker technicians using protective wear to prevent contamination. Kurt J. Lesker on-site fabrication shops offer immediate support for any necessary modifications during assembly. Functional testing of the completed systems to standard procedures and customer specifications ensures reliability and customer satisfaction. Kurt J. Lesker offers on-site system start-up and customer training for any of their systems to get your process up and running—quickly and efficiently.

Lesker LUMINOS - Manual Cluster Tool