Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Multi-Position Tube Furnace 1100C (1- 2" Dia) w/ Programmable Temperature Controller, GSL-1100X-NT-LD

Description

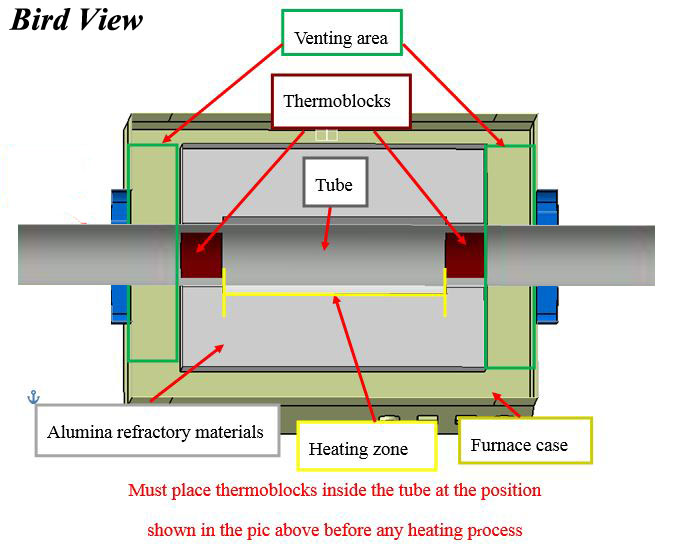

GSL-1100X-NT is a compact tube furnace (1~2" diameter) designed for firing small samples up to 1100°C. The built-in precision temperature controller can program up to 30 segments of heating rate, dwell time, and cooling rate. The furnace can be set up in both vertical and horizontal positions to meet various applications such as firing samples, VLS, CVD, and quenching tests. Set the furnace horizontally or at an angle to grow electronic crystals for the semiconductor industry use or rotate it vertically for sintering applications.

This version does not include the Stainless steel vacuum flanges with valves, vacuum pressure gauge, and quartz tube. To order the furnace with these components together, please click here.

SPECIFICATIONS:

Furnace Structure |

|

Current Rating | 15 Amps |

| Power | 1500W |

Voltage | AC 110V Single Phase or AC 220V Single Phase can be selected in the option bar |

Working Temperature |

|

Heating Rate | Max. Heating Rate: 10 °C /min |

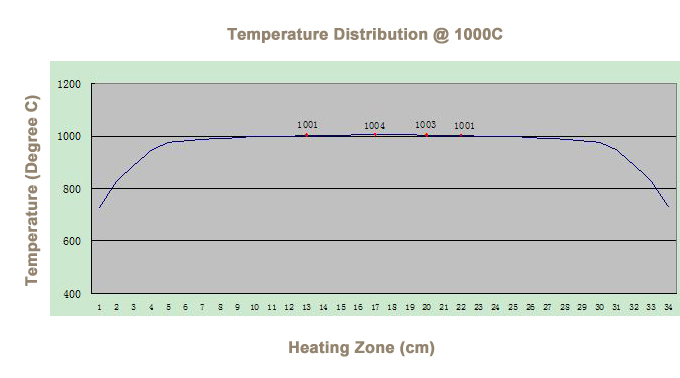

| Temperature Distribution |  |

| Heating Zone |

|

Temperature Controller |

|

| |

Heating Elements | Fe-Cr-Al Alloy doped by Mo |

Processing Tube (Sold Separately) & Tube Adapter | Two choices of quartz tubes: 2 quartz tube or quartz tube (Please find in related products)

|

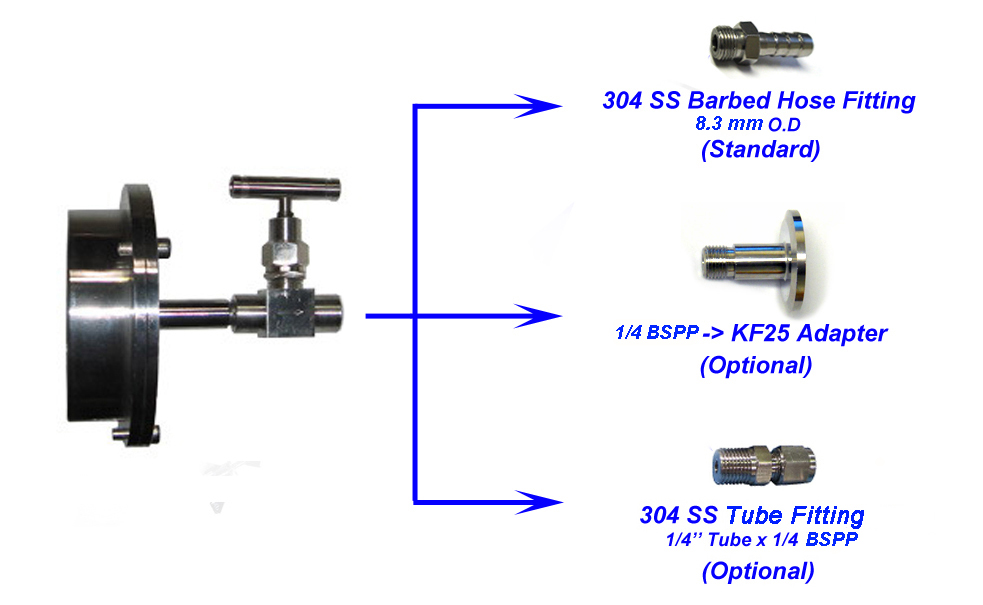

Vacuum Flange (Sold Separately) | Two choices of stainless steel flanges with vacuum gauge and valves

Options: Click on furnace picture (lower right) below to see how to insert an external thermocouple; additional furnace accessories are available for purchase. |

| |

Vacuum Pressure |

|

| A gas-type independent (above 10mbar) digital vacuum gauge with a wide range between 3.8x10-5 to 1125 Torr. Aside from greater measurement precision, this gauge reduces risks of chamber explosions caused by the incorrect reading of gas pressures due to gas-type dependency. (Please click picture left for details) | |

Dimensions |  260mm(L) x 380mm(W) x 400mm(H) (Click here for details) 260mm(L) x 380mm(W) x 400mm(H) (Click here for details) |

Shipping Package Dimensions | 40"(L) x 30"(W) x 30"(H) |

Shipping Weight | 80 lbs |

Warranty | One year limited warranty with lifetime support. |

| Compliance |

|

Application Notes |

|

Operation Instructions | |