Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

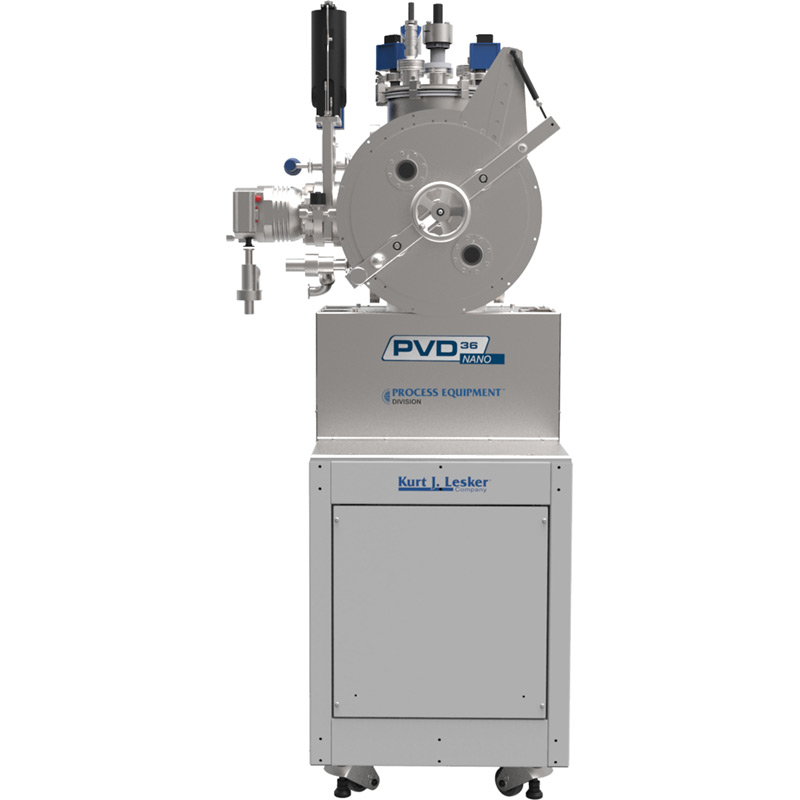

NANO 36™ – Affordable, Compact Sputtering or Thermal Evaporation Thin Film Deposition System

Description

Overview

The Kurt J. Lesker Company® NANO 36™ is our optimized, entry level deposition system. Our chamber design is uniquely suited for glovebox integration. With increased capabilities and a smaller footprint, the NANO 36 provides an accessible price point while maintaining the quality you expect from KJLC.

The NANO 36 is compatible with the following deposition techniques:

- Thermal Evaporation (up to four 2" boat assemblies)

- Torus® Magnetron Sputtering sources (up to three 2" or 3" sources)

- 1cc or 10cc LTE Organic deposition sources (up to four)

- Combination of two Thermal and two LTE sources

- Custom configurations are available upon request

KJLC's software allows user friendly recipe creation along with a reliable, uninterruptable processing module that allows process completion, regardless of the state of the computer user interface.

Features

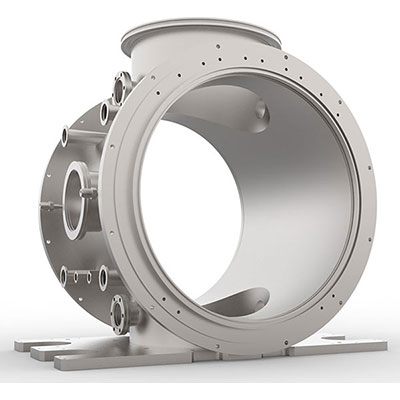

Process Chamber

|

Vacuum Pumping & Gauging

|  |

SafetyFully enclosed system electronics rack.

*System dimensions and mounting dependent on options selected. |

QualityUtilizing industry leading components allows KJLC to produce the highest quality PVD R&D tool on the market. Components and key manufacturing points are:

|  |

Options

Pumping Options

|  |

| HV Valves

|

Process Equipment Options

| Low Temperature Evaporation Sources (Up to Four)

|

Torus® Magnetron Sputtering Source (Up to Three)

For more information on our new Mag Keeper sources please see the following link. |

| (Up to Three) Power Supplies

|

Substrate Options

Substrates

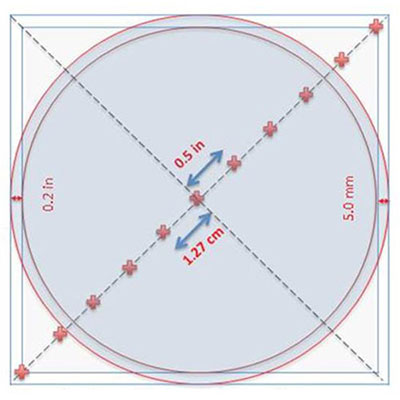

The Nano 36 is designed to allow the use of square substrates 100mm x 100mm or smaller and round substrates up to 150mm diameter or smaller. The substrate platen accommodates multiple size substrates using a KJLC multi-site fixture and substrate clips. Custom substrate/mask holders are available upon request. Standard substrate fixture options include:

|

Glovebox Adaptors

The Nano 36 is now easily integrated with a glove box. The process chamber features spring-loaded, pendulum style, full-access, aluminum doors. This new chamber design makes opening and closing the chamber door inside the glovebox a snap while providing quick and easy access to your substrate fixture and deposition sources. We also designed in a chamber back door option for glovebox integrated systems to allow chamber access while maintaining glovebox integrity.

Kurt J Lesker is able to offer a wide array of standard and custom glovebox suites, from a standard 4 port or 6 port arrangement, to custom lengths and depths.

Glovebox Specifications

- All stainless steel construction of the glovebox

- Specifically designed to integrate with KJL deposition system

- All stainless steel Swagelok valves, fittings and piping

- Modular design (for easy expansion)

- Lexan front window

- Quick release front window

- Electrical feedthrough with a six (6) outlet power strip

- LED light fixtures

- All stainless steel antechamber; size 15" diameter x 24"L with sliding tray

- Shock assisted door lifting mechanisms

- All stainless steel mini antechamber; size 8" diameter x 15"L

- Stainless steel stand with leveling feet and casters

- Stainless steel vacuum gauges

- Adjustable bin storage unit (adjustable shelving)

- Spare KF40 feedthroughs

- Two (2) HEPA gas flow filters; one (1) inlet, one (1) outlet

- Push button evacuation and refill of antechamber

- All stainless steel 24V DC solenoid valve for refill of antechamber

- Automatic electro-pneumatic valve for evacuation of the antechamber (KF40)

- Common vent line

- Stainless steel filter column for the removal of oxygen and moisture including automatic electro-pneumatic valves (KF40 size)

- Fully automatic system with Siemens PLC control unit and 7" color touch screen with built in operating instructions and system diagnostics. Includes:

- O2, H20 and pressure trending

- Maintenance alarms

- Power saver mode for vacuum pump/lights (optional)

- Automatic regeneration process using 3-5% hydrogen gas mixture

- Capable of removing 36 liters of oxygen from inert gas before needing a regeneration

- Capable of removing 1300 grams of moisture from inert gas before needing a regeneration

- Continuous oxygen monitoring

- Continuous moisture monitoring

- Includes 50 cfm circulation blower

- Built for continuous operation

- Manual solvent removal system including stainless steel filter column, 10lbs of activated carbon, manual bypass and isolation valves, evacuation and refill valves, and refill drain port (optional)

- Automatic solvent removal system including stainless steel filter column with 20lbs of molecular sieve, automatic bypass and isolation valves with automatic reactivation of filter material (optional)

- Automatic purge valve-200 L/min flow rate

Glovebox Options

Along with the gloveboxes and system adaptor boxes the following accessories can be supplied:

- Spin Coaters

- Hot Plates

- UV Ozone Curing

- Regenerable Solvent Purification System

- Other accessories upon request

Pumping:The NANO 36 offers a Pfeiffer 260 L/s turbomolecular pump and KJLC RV206 oil sealed rough pump as standard components with an option to select an Edwards nXDS6i - 3.6 cfm (6.2 m3/hr) Scroll roughing pump. Base pressure specification for the NANO 36 is 9 x 10-7 Torr. |

| Deposition:The Nano 36 offers single and multi-technique deposition options (Thermal + LTE only) including thermal evaporation and magnetron sputtering (Torus). |

Only KJLC offers Mag-Keeper sputter sources with zero o-rings in the cathode body and a magnetically coupled target to allow for easy target changes. (A game changer when changing a target through a glove box!) Our "patent pending" cooling well design enables operation at power densities ≥ 200 watts/.in2. This cathode is designed to sputter up to a 0.375" thick target on the 3" cathode and up to a 0.250" thick target on the 2" cathode. The high strength design is able to sputter up to a 0.125" thick Fe target with 3" cathodes, or 0.0625" thick Fe target with 2" Mag-Keepers. Without a hold down clamp or dark space shield this cathode is capable of running as low as ≤ 1mTorr. The unique dome shutter design eliminates the need for additional cross contamination shielding required with standard flip or swing shutters. To learn more about sputtering rates and uniformity, click here. |