Description

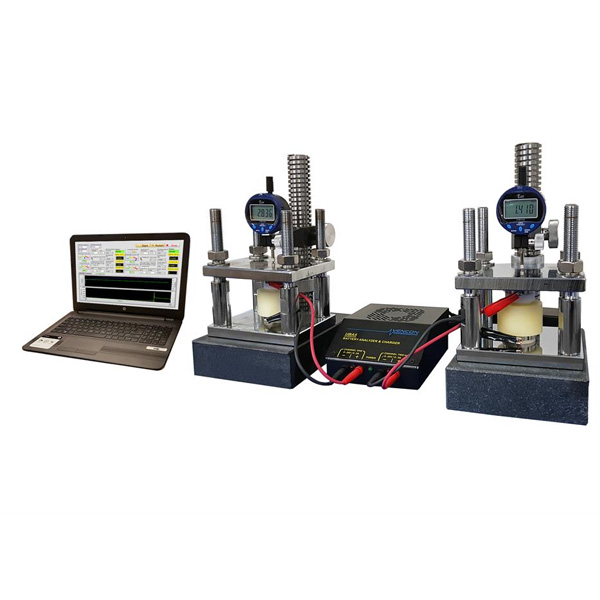

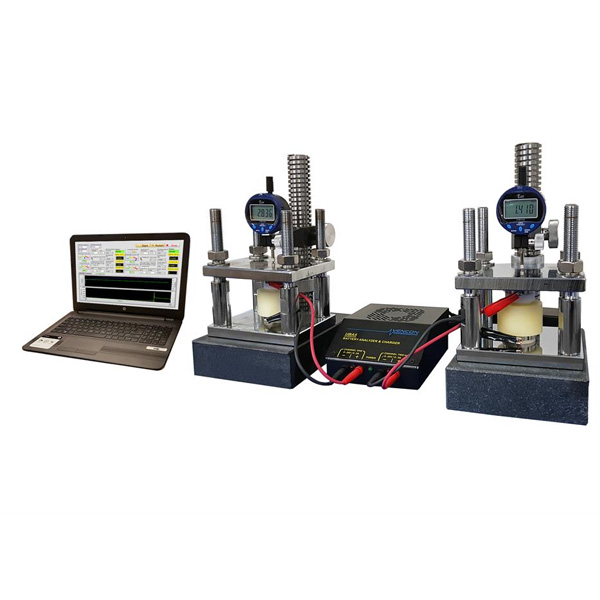

BST-UBA5-VE is an ideal solution for measuring the volume/thickness change of the electrode materials of pouch battery during the charge/discharge cycles. Such a package consists of a compact dual-channel battery cycler, load frame fixtures with precise micrometers and a lab top with Labview based testing software installed.

SPECIFICATIONS:

| Electrical Requirements | - 100~240VAC, 50/60 Hz, AC to DC adaptor is included

|

Battery Cycler Working Voltage

| - Voltage Range: 1 -15 V

- Accuracy ±0.2% rdg ±10mV

- Resolution: 1 mV

|

| Battery Cycler Charging & Discharging Current | - Charge at 1 mA - 2000 mA per channel

- Discharge at 12mA - 3000 mA per channel

- Accuracy ±0.5% reading ±2mA

- Resolution 1mA

- The power supply is with universal input 100~240VAC and 15VDC output for battery tester

|

| Testing Channels | - Two independent testing channels. Each channel can work under different modes to cycle a battery at 1mA - 2000mA, up to 15V.

|

| Power limit | |

| Data Sampling | |

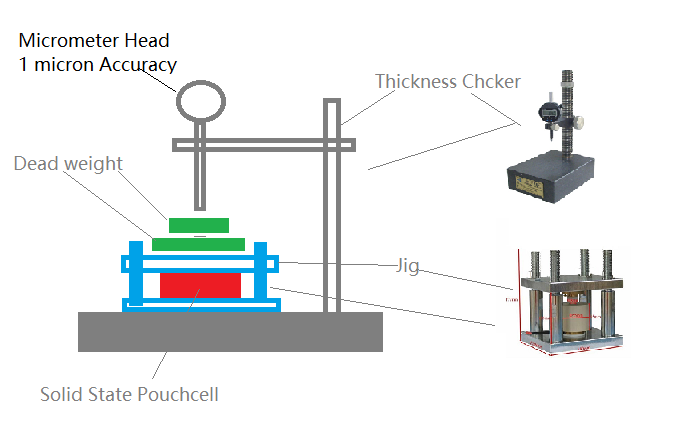

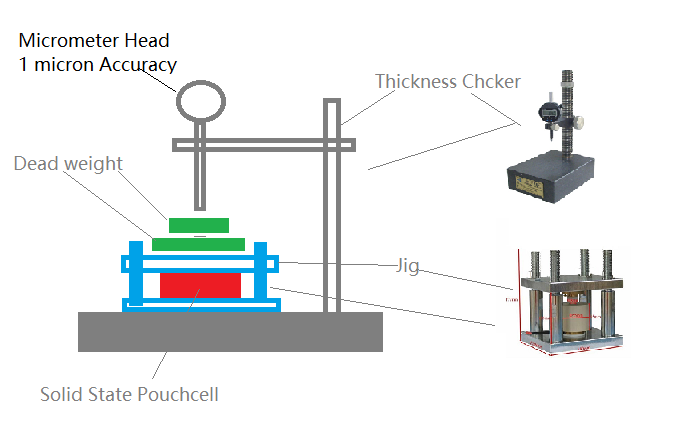

Load Frame & Micrometer   | - Working space of the frame is 90 mm L x 70 mm x 150 mm H

- You may add dead weight on the top plate or use a torque wrench to tighten the holding screws to find the critical pressure needed to confine the battery volume expansion

- Digital micrometer: 1 micron (0.001mm) resolution

- Range: 0-12.7mm

- Accuracy: 0.004 mm

- Power supply: CR2032 3V Li-ion battery

- Operating temperature: 0 - 40 °C

- The data export is available with the battery testing software. It is capable of data logging, export, statistical analysis, which is ideal for tracking battery volume expansion over multiple charge-discharge cycles

|

| Test Cell ( optional) | - Test cell ( pouch cell) up to 80x60mm area will be placed inside of load frame.

- Optional split coin cell and split pouch are available by clicking the picture below

- Test cells are NOT included in the standard package.

- The force sensor can be replaced micrometer to measure the curve of pressure vs charging/discharging

|

Software & Laptop

| - Brand new laptop with Labview based testing software is included (Supports Windows 7, 8 & 10, 64 bits).

- The software can perform various working modes (constant current charge/discharge and cycling) for evaluating cell capacity and lifecycle for all types of rechargeable batteries

- Testing graphs and curves can be created by software, such as Voltage-Current-Electrode Thickness change in the same time domain

- Limited threshold conditions include stop voltages and time

- With real-time monitoring windows and integrated graphs/data, the testing process can be observed more directly and efficiently.

- Stores all results in industry-standard spreadsheet format (A copy of MS Excel must be installed in order to view data. The user can easily analyze the performance of the batteries tested in channels both visually and statistically).

|

Miscellaneous

| - Battery input: Banana connectors (two pairs of cables with alligator clips included).

- Accessory ports Two. Allows expansion with analog inputs and digital output lines.

|

| Compliance | - Approvals CE and FCC, RoHS, and WEEE compliant.

|

| Warranty | - Two-year parts and labor against defective materials and workmanship.

|

| Operation Manual & Video |   |

| Dimension & Weight | - Battery Tester: 130mm x 170mm x 75mm (WxLxH), 820g

|

| Optional at extra cost | - Temperature probes ( 0- 100°C) for battery temperature monitoring and charge termination). ( Pic.1. $75/ea)

- Wifi adaptor which allows wireless control of the analyzer over an existing wifi network. ( Pic 2. $198)

- The high current version of the UBA5 with a 10A or 20A per channel maximum load current is available. It is designed for testing of lithium-ion single or two cell batteries. (Pic.3). The high current version of the UBA5 with 44V, 60V or 70V per channel is available ( Pic. 4 )

-

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3  Pic. 4 Pic. 4 |

Pic. 1

Pic. 1  Pic. 2

Pic. 2  Pic. 3

Pic. 3  Pic. 4

Pic. 4