| Voltage | - AC 110V or AC 220V +/- 10%

- (please select and highlight the working voltage for the cutting saw and vacuum pump in your requirement.)

|

| Motor | Brushless magnetic DC motor (110V) with variable speed up to 3,000 rpm

Power consumption: 180W |

| Effective Cutting Range | 3 dimension: X-axis: 8" , Y-axis: 4", Z-axis: 4" ( depth) |

| Moving/Cutting Speed Range | X-axis: 1-50mm/min adjustable

Y-axis: 1-50mm/min adjustable

Z-axis: 1-20mm/min adjustable |

| Accuracy | 0.0025 mm moving resolution and 0.01 mm position accuracy. |

| Cutting Blades Kits | - One 4" Dia x 0.35 mm thick fully sintered diamond blade

- Two pairs of flanges with 62 mm Dia. (for dicing) and 42 mm Dia. (for deep cutting)

|

PC Software

| - Laptop and PC software is provided with the equipment

- Cutting parameters can be set in software as cutting length, width, diameter, time, feed speed, kerf loss, etc

- Manual or programmable control mode

- Compatible with Win 7/8/8.1

- Click the pic below to view the software interface

|

| Water Cooling | - Assemblies of water jetting, draining, and Transparent plastic splashing protection is included

- The optional EQ-ECO-430 Coolant Circulating Tank is NOT included in the standard package. Please click the link to order if needed

- Adjustable nozzles are installed for re-circulating coolant

- Protective splash cover with elect cooling during tonic safety interlock installed

- For better lighting, please consider a Fiber Optic Y-shape Dual Light Microscope Illuminator

|

Accessories

| - Complete accessories are included for immediate use, including 120L/min Oilless vacuum pump,

4" diamond blade and sample holder, etc. Please see below standard package for details - One vacuum chuck (P/N ECO402) and adhesive film (P/N ECO 419) are included for dicing the thin wafer

|

| Optional | |

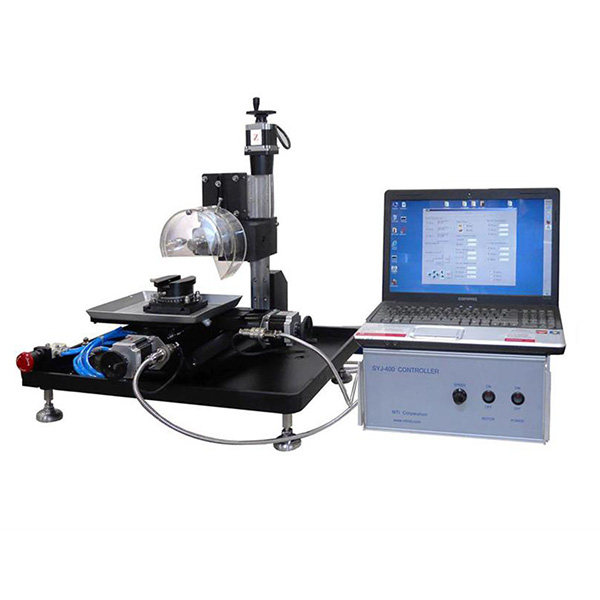

| Net WT& DIMEN | - Net Weight: 33.5 kg

- 580mm L x 560mm W x 660mm H

|

| Shipping WT & DIMEN | - Shipping weight: 190 lbs

- 48" L x 40" W x 37" H

|

| Warranty & Compliance | One year limited with lifetime support ---but not including damages caused by misuses, such as rusted parts from inadequate storage and broken parts by the user. |

| Certification | CE certified. With an additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per customer's request. |

| Operation Instruction |

|

| Application Notes | |

| Warning | - It is required to use proper cutting fluid with the saw to prevent corrosion of the machine components. We strongly recommend you use an oil-based coolant or lube cool lubricant with the water. Do not use tap water directly, otherwise, the rusting component is not part of the warranty

- Never cut any materials without the use of proper cutting fluid. If you do so, serious damages can be caused by the spooler driving mechanism

- For cutting the sticky materials such as non-ferrous alloy, epoxy, and plastic, you must sharpen the diamond blade frequently. We suggest that cutting the sample along with the included dressing stone (Glue sample and the dressing stone side by side and cut them together, this process will help keep the blade sharp enough for efficient cutting

- Please clean the machine after the completion of each use, especially the lead screw using WD-40 lubricant (1 can include) after each use. Make sure the X, Y and Z axes can move freely without blocking and rusting

- If you don't know what is the best cutting speed for your material, please try to speed from low (2 mm/minute) to high (6 mm/minute). Harder material needs lower speed to avoid blade or sample broken

|