| Power | - 110V - 240V AC 50/60Hz for worldwide use

- 280W

- UL /CSA certified power supply (110~ 240VAC - 24VDC) is separated from the coating unit

- The coating unit has 24VDC input and is driven by a 24VDC motor, which can be used under the Ar atmosphere glovebox to avoid NRTL certification

|

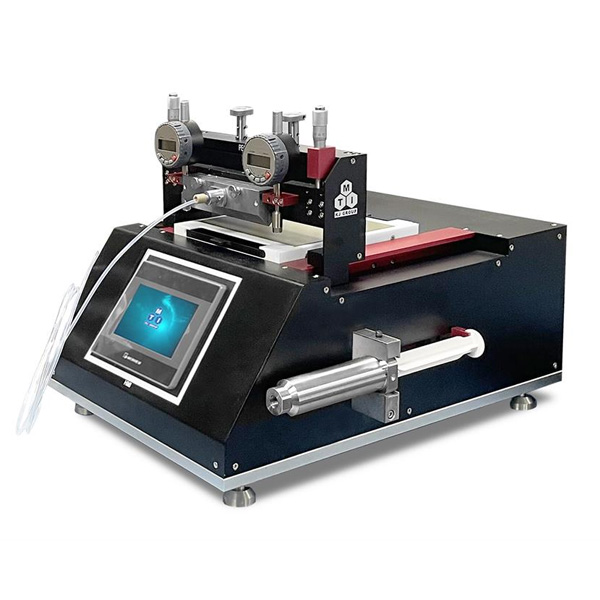

Slot Die head

| - 100 mm width slot die head capacity

- A set of shims, 0.08 mm, 0.1 mm, 0.2mm, 0.3mm, 0.4mm, and 0.5mm thickness, are included.

- Different-width shims are available upon request. ( 12- 50 mm width )

- Minimum coating thickness: 5 microns (depended on slurry viscosity)

- Tube connection: M6 connector with 3mm OD tube from the middle of the head.

- EQ-SDH Die Heads do NOT fit this Coater directly. A customized adapter has to be used (figure below).

-

|

Syringe Pump

| - Built-in syringe pump with a variable speed in the range from 0.05 to 5.0 mm/s

- Touch screen panel for setting up the parameters

- One 20mm stainless steel syringe with a plastic plunger is included.

|

Gap Control

| - Two micrometer heads are built in the travel rod of the coater to adjust the gap between the slot die and the substrate

- Two digital drop indicators are provided to move with the slot die.

|

| Tavel Speed & Length | - Travel Speed: 0.05 - 30 mm/s adjustable via touch screen control panel

- Maximum coating area: 100 mm W x 100 mm L

|

| Heated Vacuum Chuck

| - Vacuum chuck made of aluminum alloy with small holes

- The small vacuum pump is built inside the coater and driven by a 24VDC motor

- Vacuum chuck Area: 150mm (W) x 130mm (L)

- Surface roughness: ≤ 5 μm

- Surface flatness: ≤ 15 μm

- Linear Motion Levelness: ≤ 20 μm

- Heating elements are installed inside the chuck which can reach 120 ºC

- Precision digital temperature controller with ± 1ºC accuracy

|

| Control Panel | - 4" color touch screen panel to set coating speed, heating temperature, and syringe pump speed

|

Options

| - In order to achieve better coating by the slot die, the slurry's viscosity and dispersion is very important, please click the picture below to order a viscosity meter and dispersing machine and find the best parameter for your coating

-

|

| Product Dimensions

|  440mm L x 340mm W x 300mm H 440mm L x 340mm W x 300mm H |

| Compliance | CE certified

NRTL or CSA certification is available upon request at extra cost |

| Warranty | One year limited warranty with lifetime support |

| Operation Video |   |

| Net Weight | |

| Shipping Weight & Dimensions | |

| Application Note | - Coating thickness is not dependent on or equal to the gap between the slot die head and substrate.

- Usually, the gap shall be larger than the coating thickness. Coated thickness is strongly dependent on slurry viscosity, coating speed, and flow speed. ( Lower viscosity, low flow rate, and low speed will result in the thinner film. Please practice finding the best parameters which suitable for you

- Example: 5% carbon+ polymer, viscosity: 500mPa·s, substrate: Al foil of 16 um,

- Gap: 200 um, Slurry feeding rate:: 0.1 ml/minute , Coating speed: 12mm/s

- Dry coated film thickness: 5 um +/- 1 um

|