Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Roll to Roll Coating System (Max. 250mm W) with 3 Optional Coating Heads - MSK-AFA-300-LD

Description

MSK-AFA-300 is a Roll-to-Roll continuous coat with 3 optional coating heads for materials research labs.

MSK-AFA-300 is a Roll-to-Roll continuous coat with 3 optional coating heads for materials research labs.

This system integrates the functions/ features of reeling in & out, slurry feeder, coating blade, baking oven, and final electrode winding (reeling in).

It can coat electrode sheets up to 250mm in width and 500 meters in length automatically.

For Roll to Roll Coater Service, please fill out and submit the Roll to Roll Coating Service Request Form

Note 1: MSK-AFA-E300-UL is updated from MSK-AFA-E300 with all UL certified electric parts from June 1, 2014, which are ready to pass UL or TUV test at extra cost.

Note 2: Starting July 10th, 2015, the "Intermediate Coating" mode will be offered on all units as standard features.

Note3: upgrade to three coating heads optional

SPECIFICATIONS:

Power |

|

3 Type of Coating Heads (Optional)

| Please select the option bars to choose the coating head/method

Pic. 1 Pic. 2 Pic. 3 Pic. 4 Pic. 5 Pic. 6 |

Max. Coating Width | 250mm |

Thickness adjustable range | 0 - 5mm |

Coating thickness (after drying) | 5 - 200um (for most kinds of battery electrode coating material) |

Thickness Precision | ± 3µm (± 5µm at edges) |

Coating Speed | 0-750 mm / minute |

Max. Drying Temperature | 120°C ( Using a 240V transformer, can reach 150°C max.) |

Temperature Accuracy | ±1°C |

Heating Zone Length | 710mm (28") |

| |

Max. Reeling/Unreeling Diameter | 250mm (OD) |

Max. Coating Length |

|

SS316 Moving Rod | |

Exhaust Port Size | 127mm O.D |

Control Panel |

|

Acessories included | |

Compressed Air | 0.5-0.8 MPa Air compressor is required, but not included. Please click here to order) |

Optional Slurry Feeding Pumps |

|

Optional

|

|

Product Dimensions | |

| |

Warranty |

|

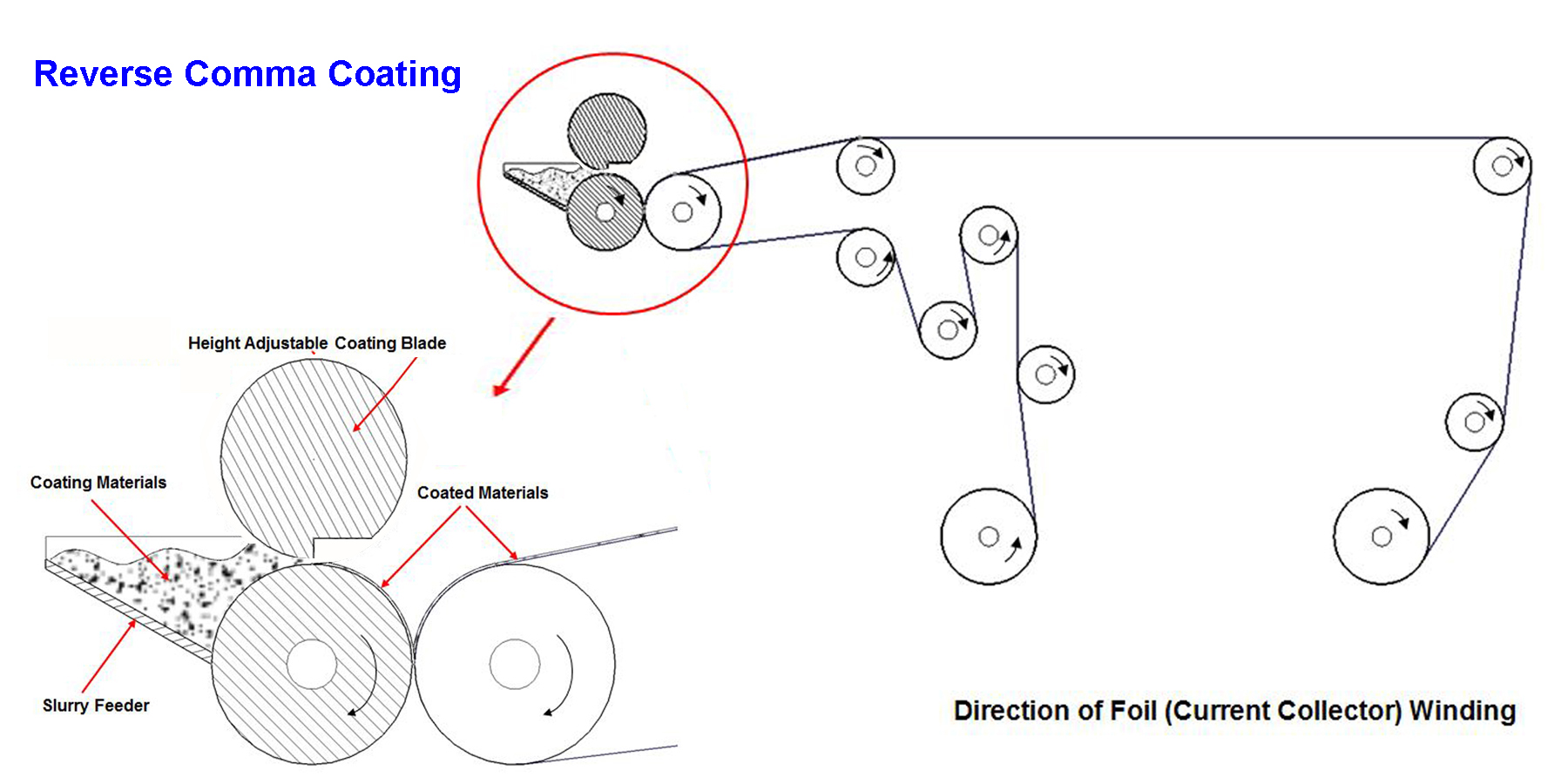

| Operation Video |     Reverse Comma Coating Slot Died CoaSting How to make Pouch Cell Howto Make Cylinder cell |

| Net Weight | 1000 kg (2200 lbs) |

| Shipping Dimension | 70" x 45" x 55" |

Pic.1

Pic.1

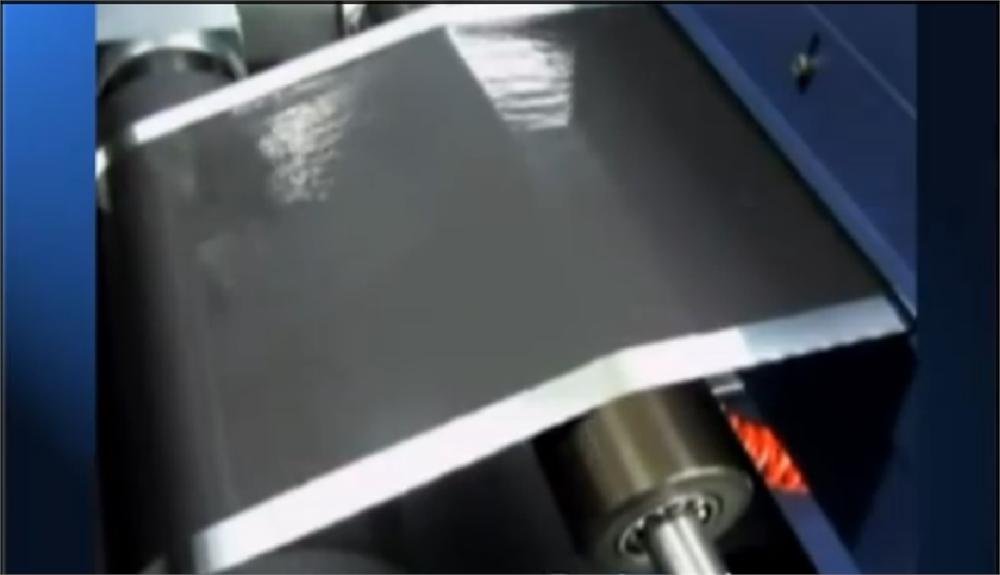

Pic.3

Pic.3  Pic. 4

Pic. 4