Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

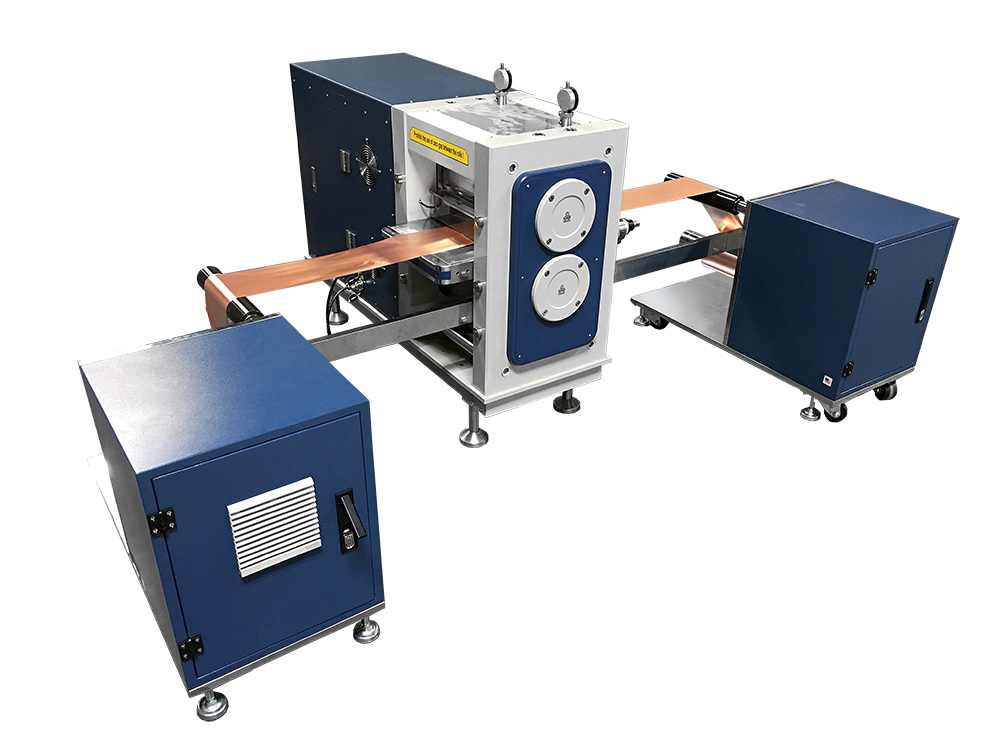

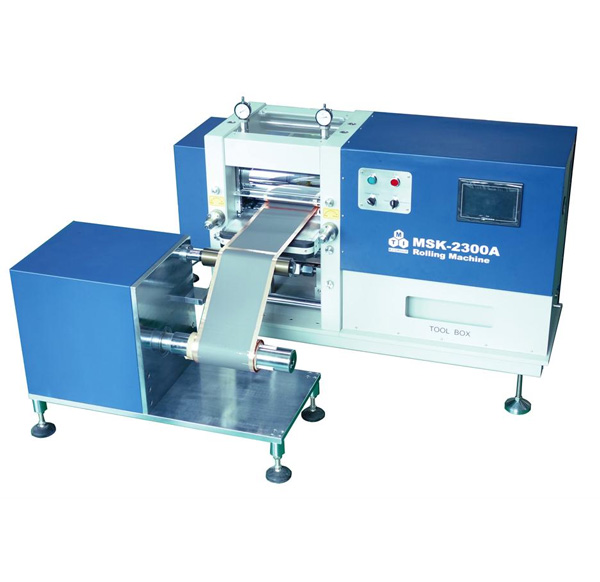

Roll to Roll Pressure Controlled Rolling Pres for Battery Electrodes (Max. 300mm Width) - MSK-E2300B

Description

MSK-E2300B is an Automatic Battery Electrode Rolling Press System with precision digital pressure control in a compact footprint that is less than 6'x6'. It integrates tension controlled feeding and winding devices together with Pressure Controlled Electric Rolling Machine to achieve attention-free electrode rolling & pressing up to 75 meters long with the 300mm max-width. It is a perfect tool for building prototypes (e.g. pilot scale studies) of new generation rechargeable batteries to prepare electrode sheets at consistent and repeatable rolling conditions.

SPECIFICATIONS:

Working Voltage |

|

Max. Power Consumption |

|

Rollers (one pair) |

|

| Press gap |

|

| Motor & Rolling Speed |

|

| Roller Surface Hardness |

|

Press Planeness | ±0.0025mm |

Pressure Control | |

Rectifying Sensor | Built-in Rectifying Sensor to ensure neatly reeling electrode foil after pressing |

Compressed air | 60psi required (Air compressor is not included. Please click here to order) |

Rolling Unit Dimensions |

|

Compliance & Warranty |

|

Application Notes |

|

| Articles | |

Operation Video |     |

Net Weight | 1000 kg (2200 lbs) |

Shipping Weight & Dimensions |

|