Furnace Structure | - Double-layer steel case with two cooling fans, which ensure low surface temperature

- High purity fibrous alumina insulation for energy saving

|

Power | 10KW (75A air breaker required ) |

Voltage | AC 220-240 Single Phase, 50/60 Hz |

Max. Temperature | Zone one: 1400 °C (1500 °C<1hour), Zone two: 1700 °C Zone Three: 1400°C (1500 °C<1hour) |

Max. Heating Rate | <=10 °C /min |

Normal Heating/cooling Rate | 5°C /min |

Thermal Block Placement | - Two thermal blacks are included. Please picture below to learn how to place them inside the tube

- You may order flange support to avoid tube rotating ( click Pic below right )

.jpg) |

| Heating Zone Length | - Three zones: total 25" (630 mm) heating zone (included two refractory separators)

- Zone 1: 7.5" (190 mm) heated by 4 pcs U type SiC(30x300 mm)

- Working temperature 400 - 1400°C (1500 °C<1hour)

- Heating rate: 10°C/min

- Zone 2: 10" (250 mm) heated by 6 pcs U type MoSi2(30x300 mm)

- working temperature 800 - 1700°C

- Max. Heating rate: 5°C/min

- Zone 3: 7.5" (190 mm) heated by 4 pcs U type SiC(30x300 mm)

- Working temperature 400 - 1400°C (1500 °C<1hour)

- Max. Heating rate: 10°C/min

- Constant Temperature Zone Length ( 3 controllers at the same temperature): 200mm with+/- 1C)

|

Tube Size and Flange

| - 99.8% purity Alumina Tube

- 2-3/8" ( 60mm) O.D.x 2-1/8"I.D. (54mm) x 48" (1200mm) Length

- 60 mm stainless steel vacuum sealing flange with valve and meter is included

- For 80mm & 100 mm O.D. options, tube length: 1500 mm

- Two porous ceramic blocks are included for protecting flange from heating radiation

- Vacuum pressure can reach to 10-4 torr with the turbo vacuum pump

|

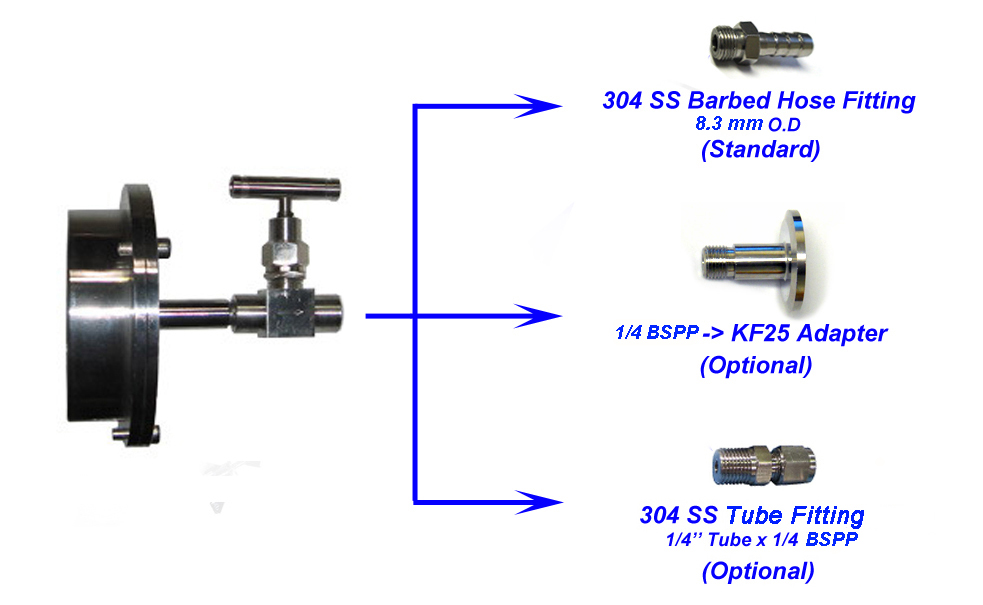

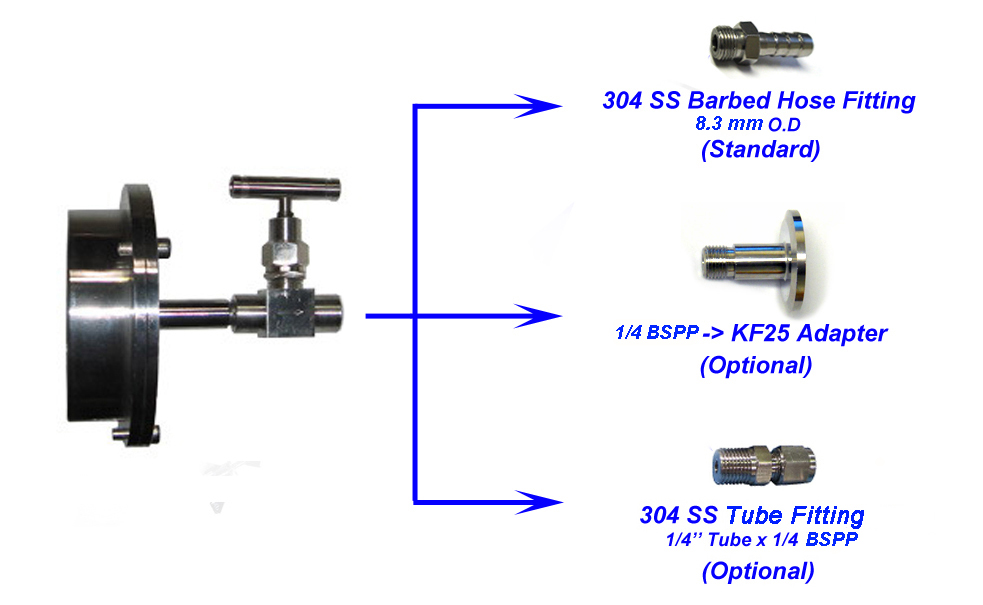

Fitting Ports

| - In order to increase the throughput and achieve high vacuum, you may replace the standard barbed hose fitting with the KF25 adapter, please click underline to order.

For supplying high-pressure gas, you may replace the standard barbed hose fitting with the Swagelok Tube Fitting, please click underline to order |

Temperature Controllers | - Three digital controllers with microprocessor-based PID control and self-tuning

- Each has 30-segments programmable with protection for overheated and broken thermocouple

- Temperature Accuracy: +/- 1ºC

- Thermal Couple: One B type(210mm long TC for the central zone), two S type (210mm long TC for side zones)

|

European Temperature Controllers (optional upgrade)

| - 1 heating channel

- 1 program of 8 or 24 segment

- Alarm Relay: Form 'A' and Form ‘C’ built-in

- Digital Communications: RS485

- Temperature Accuracy: ± 0.1ºC

- Recipes: Using a PC tool recipes can be created that can be used to change the operating parameters of the 3000 simply by selecting a new recipe via the HMI. This is very useful where multiple products are processed using the same controller but require different parameters to be set.

|

Power Cable & Plug

| - 10 feet length 8-3 AWG heavy duty UL approved power cable is included

- Extra length cable can be ordered by click picture left

- The plug is not included. You can order from the local hardware store according to female plug in your lab

|

Dimensions | 863 L x 457 W x 711 H mm (34 L x 18 W x 28 H inch) |

Net Weight | 150 kg |

Warranty | One year limited warranty with lifetime support(Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)

- Labview Based Temperature Control System (EQ-MTS01) enables user to edit temperature profile, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters operating range.

- The above features are available upon request at an extra cost (up to $1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance | - CE Certified

- NRTL or CSA Certification is available upon request, additional charges will apply

-

|

| Operation Instructions |   |

Shipping Package Size After Crating | 47"x45"x45"(1200L x 1150W x 1150Hmm) |

Shipping Weight | 180 kg |

Application Notes | |

Optional Parts | |

Warnings

Please click here to learn the installation of a gas regulator. Please click here to learn the installation of a gas regulator. | - The tube furnaces with alumina tube are designed for use under vacuum and low pressure < 0.02 Mpa / 0.2 Bar/ 3 PSI

- Never use graphite crucible in the alumina tube.

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- The gas flow rate should be limited to < 200 SCCM ( or 200ml/min )

- Vacuum limit definition for all alumina tube furnaces: * Vacuum pressures may only be safely used up to 1500°C

|

.jpg)

Please click here to learn the installation of a gas regulator.

Please click here to learn the installation of a gas regulator.