Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

- UV Drying & 10K RPM Programmable Spin Coater for 3“ wafer Max. - VTC100B-UV

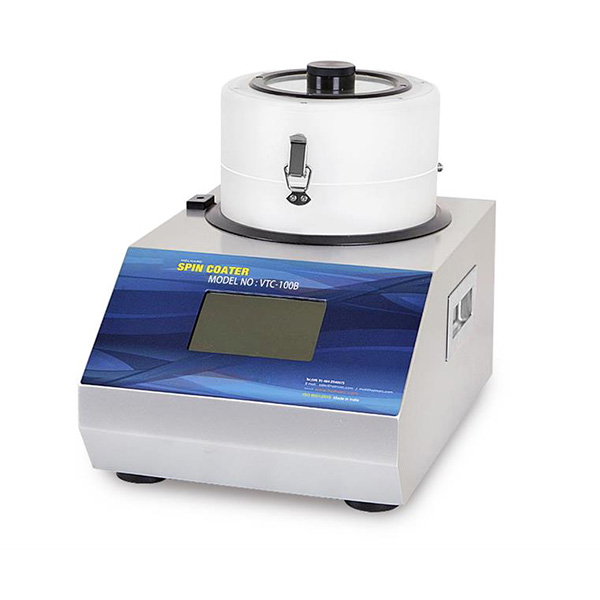

UV Drying & 10K RPM Programmable Spin Coater for 3“ wafer Max. - VTC100B-UV

Description

VTC-100B-UV has a touchscreen display Readout tabletop spin coating device dedicated to spin coat small substrates between 30 mm to 70 mm. UV LED curing system is used whenever there is a need for curing and drying of coatings. It also provides gases purge facility for an additional supply of gases inside the chamber. Vacuum Chucks provide flat, rigid surfaces for mounting substrates of different sizes and shapes. A vacuum chuck powered by oil-less vacuum pump holds the substrate at the spinning head. The syringe holder height can be adjusted and rotated freely along the support rod. All required safety measures are provided for high-speed rotation and spillage. It also provides a facility for drainage.

SPECIFICATIONS:

| Structure |

|

| Input Power |

|

| Vacuum Chuck & Vacuum pump |

|

| Actuator | Brushless DC motor |

| Touch Panel with Digital Control |

|

| Liquid Injecting |

|

| Gas Inlet | 6mm diameter gas inlet port allows customers to fill desired gasses into the chamber, which can make coating under variable gas flow environment. |

| Product Dimensions |  400 x 275 x 331 mm (L x W x H) 400 x 275 x 331 mm (L x W x H) |

| Weight | 34 kg (75 lbs) |

| Compliance |

|

| Warranty |

|

| Operation Manual & Video | |

| Warnings |

|