Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Vacuum Planetary Centrifugal Mixer w/ Two Containers (300ml) & Optional Ball Mill Jars - MSK-PCV-300-LD

Description

The planetary centrifugal vacuum mixer MSK-PCV-300-LD is designed for mixing and deaerating various kinds of liquid, slurry, paste, and powder materials. It could be used for mixing and homogenizing nanopowders, nanotubes, ceramics powders, battery powder/slurry, metal powders, and especially high viscosity slurry/paste. The vacuum mixing capability is integrated for the best mixing results. The standard package includes two 300 ml of containers and counter-weights. High-throughput adapters are also available for 6 samples (7 ml per sample) mixing per batch. Also, you can use the device as an ultra-high-energy ball milling up to 600 G impact force with special alloy jars. SPECIFICATIONS

Features |

| ||||||||||||||||||||

| Voltage Input |

| ||||||||||||||||||||

| Power |

| ||||||||||||||||||||

Mixing

|

| ||||||||||||||||||||

| Vacuum Capability |

| ||||||||||||||||||||

| Speed |

| ||||||||||||||||||||

| Containers and Counter-Weights | |||||||||||||||||||||

| Optional containers |

Pic. 1 Pic. 2 Pic. 3 Pic. 4 Pic. 5 Pic. 6 | ||||||||||||||||||||

| Max. Mixing Volume and Weight |

| ||||||||||||||||||||

| Control Panel |

| ||||||||||||||||||||

| Safety and Protection |

| ||||||||||||||||||||

| Warranty |

| ||||||||||||||||||||

| Dimension | |||||||||||||||||||||

| Weight |

| ||||||||||||||||||||

| Shipping Weight & Dimensions |

| ||||||||||||||||||||

| Operation Video and Instructions |  How to mixing How to mixing  How to ball milling How to ball milling | ||||||||||||||||||||

| Application Notes |

|

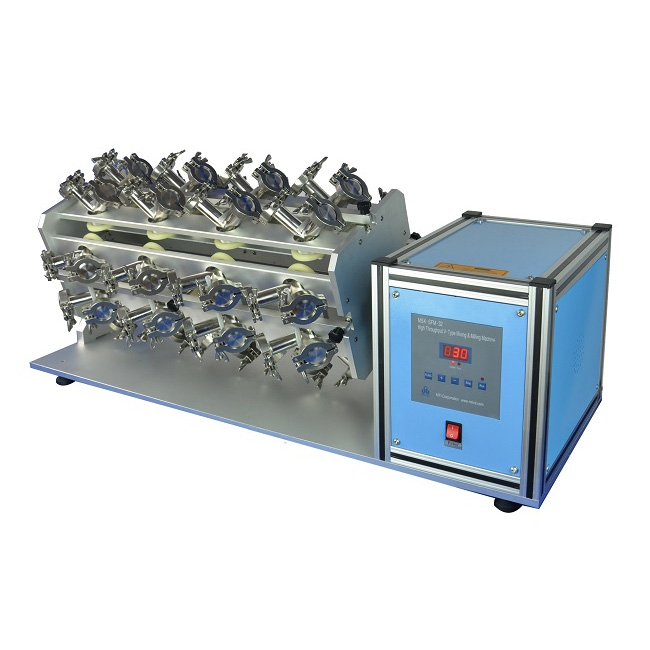

MSK-SFM-32 is a high throughput mixing and milling machine that has 32 stainless steel tank with 50 ml capacity. The special V-shaped mixing tank is designed for grinding and mixing dry powders in short periods of time for 32 kinds of composition. A digital control panel enables the rotary speed and time duration of the mixing session to be programmed easily. The mixer can be used inside a glove box under Ar gas because of 24VD Motor Driven. It is an excellent tool for material MGI research.

SPECIFICATIONS

Features

|

|

| Input Voltage |

|

| Timer Setting Range | 1~900 min |

| Rotary Speed | 20~70 rpm |

| Dimensions and Capacity | |

| Optional grinding balls | Please click the picture below to choose a grinding ball made of stainless steel, alumina YSZ and Agate

|

| Overall Dimensions |  |

| Weight | 50 Kg |

| Compliance |

|

| Warranty |

|

| Operation Manual & Video |   Demo Video Operation Video |

| Optional |

|